Production skills management: How to define, assess and track skills on the shop floor

Production skills management is the process of defining, assessing, and tracking the competencies needed to run production safely and efficiently. Without it, manufacturers face unqualified operators on critical equipment, expired certifications during audits, and production bottlenecks caused by insufficient cross-training.

Production skills management is the process of defining, assessing, and tracking the skills and competencies needed to run production safely and efficiently, from frontline operators to production managers. In today’s manufacturing environment, where quality standards, safety regulations, and customer demands are constantly evolving, having a systematic approach to managing skills isn’t optional, it’s essential.

Without proper skills management, manufacturers face significant risks: unqualified operators on critical equipment, expired certifications during audits, knowledge gaps when experienced workers leave, and production bottlenecks caused by insufficient cross-training. As a result, these issues directly impact throughput, quality, safety performance, and ultimately, profitability.

This guide covers everything production and plant managers need to know about production skills management: the key roles and their responsibilities, essential hard and soft skills for today’s production teams, how to build and maintain skills matrices, the best tools and software solutions, and practical implementation strategies you can use right away.

What is production management, and where do skills fit in?Copied

Production management is the systematic oversight of manufacturing operations, including the coordination of materials, labor, equipment, and capital to transform inputs into finished products at the desired quality, cost, and delivery performance. Production managers handle several key responsibilities: planning production schedules, managing budgets, ensuring quality standards, maintaining workplace safety, and optimizing resource use.

Why skills management is central to production success

Skills management sits at the heart of production management because every production goal depends on having the right skills in the right roles at the right time. Whether you’re hitting throughput targets, maintaining zero-defect quality, or achieving safety milestones, success requires skilled people.

However, as production operations scale and complexity increases, relying on tribal knowledge, spreadsheets, or memory becomes increasingly risky. What worked when a single manager knew every employee’s capabilities becomes impossible when managing dozens or hundreds of workers across multiple lines and shifts.

How a skills matrix solves production challenges

That’s where a skills matrix provides real value. It gives you a structured way to document who can perform which tasks at what level. As a result, you can staff shifts with confidence, spot training needs systematically, and keep compliance docs ready for audits, all while cutting the risk of production hiccups caused by skills gaps.

Common production challenges that skills management solves

Consider these production challenges:

- A critical machine goes down, but the only qualified technician is on vacation

- An auditor asks for proof of operator certifications, and you’re scrambling through folders and emails

- A new product launch requires specialized skills that only a few team members have

- High performers retire, taking years of institutional knowledge with them

All of these scenarios stem from weak skills management. Moreover, as operations scale and get more complex, relying on tribal knowledge or spreadsheets becomes riskier. Therefore, a skills matrix provides the visibility and structure you need to handle these challenges proactively.

Key roles in production (and what they’re responsible for)Copied

Building an effective skills management system starts with understanding the different roles on the shop floor and how their work connects. While job titles and org structures vary across companies, most production operations include these core roles:

Production manager / Plant manager

The production manager (also called plant manager or operations manager in some organizations) holds ultimate responsibility for manufacturing output, quality, cost, and safety. This is both a strategic and tactical role that requires balancing competing priorities while maintaining operational excellence.

Core responsibilities include:

- Planning and organizing production schedules to meet customer demand while optimizing resource use

- Managing production budgets, controlling costs, and tracking financial KPIs like cost per unit and variance

- Ensuring quality standards through systematic inspection, testing, and continuous improvement

- Maintaining health and safety compliance, conducting safety training, and investigating incidents

- Overseeing staff including hiring, performance management, training, and succession planning

- Managing bottlenecks through capacity analysis and resource reallocation

- Coordinating with procurement for materials, maintenance for equipment uptime, and logistics for on-time delivery

In essence, production managers need to be equally comfortable on the shop floor and in the conference room. They translate strategic business goals into operational reality while solving immediate production challenges.

Production supervisors and line leaders

Production supervisors and line leaders serve as the critical link between management strategy and frontline execution. They translate production plans into shift-level work assignments, monitor real-time performance, and solve problems as they pop up.

Key responsibilities:

- Leading daily shift operations and managing production flow to meet targets

- Coaching and developing operators through on-the-job training and performance feedback

- Monitoring KPIs such as cycle time, scrap rates, and OEE (Overall Equipment Effectiveness)

- Running quality checks and making sure standard operating procedures are followed

- Responding to equipment issues, material shortages, and quality problems in real-time

Effective supervisors combine technical knowledge with people skills. They keep production moving while developing their team’s capabilities.

Production operators

Production operators are the hands-on workforce who run equipment, perform changeovers, conduct quality checks, and handle preventive maintenance tasks. Their technical skills and attention to detail directly determine production output and quality.

Typical responsibilities:

- Operating production equipment according to standard procedures and safety protocols

- Performing equipment changeovers and setups for different product runs

- Running in-process quality inspections and documenting results

- Performing routine maintenance tasks like cleaning, lubrication, and minor adjustments

- Spotting and reporting equipment problems, quality issues, and safety hazards

While each role has distinct responsibilities, they form a connected system. Production managers set direction and allocate resources, supervisors translate plans into action and coach teams, and operators execute the work with skill and precision. A unified skills tracking system makes sure all roles have the skills they need to perform well.

Essential skills for production managers (and their teams)Copied

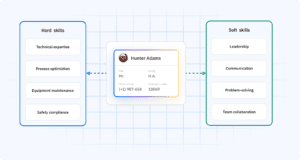

Production roles need a mix of technical expertise and people skills. The specific skills vary by role, but successful production operations depend on having depth in both hard skills (technical knowledge and process mastery) and soft skills (leadership, communication, and problem-solving).

Core hard skills

Technical skills form the foundation of production excellence. These are the capabilities that directly affect production output, quality, and efficiency:

Production planning & scheduling

The ability to create realistic production schedules that balance capacity constraints, material availability, labor resources, and customer delivery requirements. This includes understanding bottleneck management, sequencing logic, and resource optimization techniques. Production managers need to be skilled with planning tools and methods like MRP (Material Requirements Planning) and finite capacity scheduling.

Lean manufacturing & continuous improvement

Knowledge of lean principles including waste reduction (the 8 wastes: defects, overproduction, waiting, non-utilized talent, transportation, inventory, motion, extra processing), value stream mapping, 5S workplace organization, Kaizen events, and standardized work. According to KnowledgeHut research on essential production management skills, understanding how to spot and fix improvement opportunities is critical for staying competitive.

Quality management & root cause analysis

Expertise in quality control tools and methods including statistical process control (SPC), control charts, capability analysis (Cp/Cpk), failure mode and effects analysis (FMEA), and root cause analysis techniques like 5 Whys and fishbone diagrams. Production managers also need to understand CAPA (Corrective and Preventive Action) processes and how to respond to audit findings systematically, skills frequently highlighted in production manager job postings.

Technical process knowledge

Deep understanding of the specific manufacturing processes in your operation, whether that’s machining, assembly, injection molding, stamping, welding, packaging, or other processes. This includes knowing equipment capabilities and limits, process parameters and their effects on quality, material properties and behavior, and how to troubleshoot common issues.

Data & KPI literacy

The ability to collect, analyze, and act on production data. Key metrics include OEE (Overall Equipment Effectiveness = Availability × Performance × Quality), scrap and rework rates, first pass yield, throughput, cycle time, on-time delivery percentage, and labor productivity. Production managers need to be comfortable with data visualization tools and using data to drive decisions rather than relying on gut feel alone.

Core soft and managerial skills

While technical skills get the work done, soft skills determine how well teams work together, adapt to change, and keep performing over time:

Leadership and people management

The ability to inspire and develop teams, provide clear direction, delegate well, and hold people accountable while keeping morale up. Strong production leaders create a culture where operators and supervisors feel empowered to solve problems and suggest improvements. This includes coaching, giving constructive feedback, recognizing contributions, and managing performance issues fairly.

Communication and conflict resolution

Production environments need constant communication: shift handoffs, safety briefings, production meetings, and cross-functional coordination. Good communicators adapt their message to the audience (executives vs. operators), listen actively to understand issues before responding, and address conflicts constructively before they blow up. This matters especially in diverse, multi-shift operations where poor communication can lead to costly mistakes.

Time & priority management

Production managers juggle multiple competing priorities: urgent equipment repairs, scheduled meetings, quality investigations, staffing issues, and strategic projects. The ability to triage well, focus on high-impact activities, and avoid getting pulled into every small problem is essential. This includes delegating appropriately and knowing when to escalate vs. when to solve things yourself.

Problem-solving and decision-making

The capacity to analyze complex situations, identify root causes, evaluate alternatives, and make sound decisions under pressure. Production managers face constant trade-offs: Should we run overtime or miss a deadline? Should we repair or replace this aging equipment? Should we stop production for this quality issue or continue with extra inspection? Strong decision-makers gather relevant data, think through consequences, consult stakeholders when appropriate, and commit to a course of action decisively.

Emerging skills for production managers in 2026 and beyondCopied

The skills needed for production management keep evolving as manufacturing adopts new tech and responds to market pressures. Forward-thinking manufacturers are building these capabilities now:

Advanced technology integration

Modern production increasingly involves automation systems, industrial IoT sensors, real-time data dashboards, predictive maintenance algorithms, and collaborative robots. Production managers don’t need to be software engineers, but they must understand how these technologies work, what problems they solve, and how to manage the human-technology interface. This includes evaluating technology investments and leading digital transformation on the shop floor.

Sustainability and resource efficiency

Environmental regulations and customer demands are pushing manufacturers toward sustainable practices. Production managers need skills in energy management, waste reduction, circular economy principles, and environmental compliance. This goes beyond just meeting regulations, leading manufacturers are finding that sustainable operations also drive cost savings through less material waste, lower energy use, and better process efficiency.

Cross-functional collaboration

Production no longer operates in isolation. Successful production managers work well with engineering (for design for manufacturability and process improvements), supply chain (for material planning and supplier quality), quality assurance (for systematic problem-solving), maintenance (for equipment reliability), and even sales and marketing (to understand customer needs and manage expectations). Being able to speak the language of other functions and find win-win solutions is increasingly valuable.

Here’s the key point: the skills profile for production management is shifting and will keep evolving. Production skills management can’t be a one-time exercise where you define roles and forget about them. It needs to be dynamic, regularly updated to reflect changing technology, customer requirements, and competitive pressures.

What is production skills management?Copied

Now that we’ve covered the roles and skills that matter in production, let’s define production skills management clearly:

Production skills management is the systematic process of mapping the skills and competencies needed for each production role, assessing current employees against those requirements, and maintaining this information over time to guide staffing decisions, training investments, and operational improvements.

The scope of production skills management

It’s part of the broader category of manufacturing skills management platforms and tools, but with a specific focus on the frontline: production managers, supervisors, operators, technicians, and other shop floor roles.

Production skills management covers several key activities:

Key activities in production skills management

- Skills definition. Identifying what skills and certifications are required for each role and task

- Skills assessment. Evaluating employees’ current skill levels through testing, observation, and certification tracking

- Skills documentation. Recording skills data in a format that’s accessible, accurate, and audit-ready

- Skills analysis. Using skills data to spot gaps, plan training, and make staffing decisions

- Skills development. Running training programs and cross-training initiatives to close gaps and build backup strength

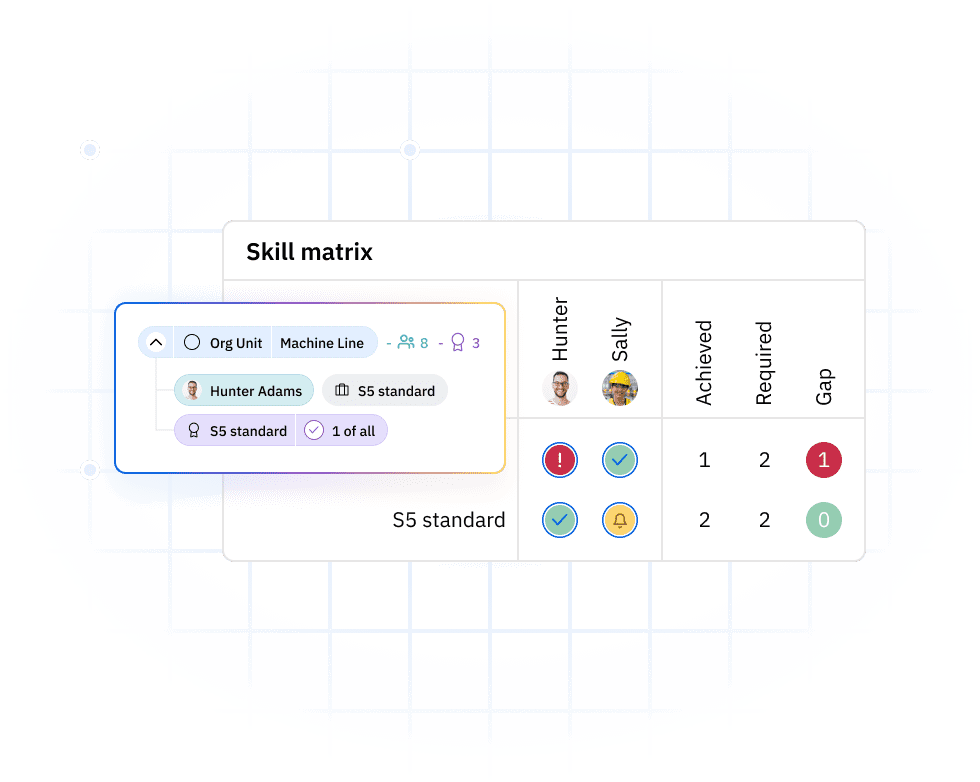

The most common tool for production skills management is the skills matrix, a visual representation that shows which employees have which skills at what level. A production skills matrix typically shows skills as rows (or columns) and employees as columns (or rows), with proficiency marked by numbers, colors, or labels like ‘beginner,’ ‘proficient,’ ‘expert.’

Limitations of spreadsheet-based skills tracking

However, static skills matrices kept in spreadsheets have some real limits:

- They get outdated quickly as people gain skills, certifications expire, and requirements change

- They’re hard to maintain across multiple shifts, lines, or facilities

- They don’t alert managers to expiring certifications or training needs

- They’re prone to version control issues and data entry errors

- They’re a pain during audits when you need to quickly prove compliance

That’s why many manufacturers are moving from spreadsheets to dedicated skills matrix and skills management software. These platforms give you real-time visibility, automated alerts, integration with training systems, and audit-ready reports, all critical as production gets bigger and more complex.

How to build a production skills management system (Step by step)Copied

Building an effective production skills management system doesn’t require a massive transformation project. You can start with basic tools and scale up as needs grow. Here’s a practical step-by-step approach:

Step 1: Map your production processes and roles

Before defining skills, you need clarity on your production structure. Start by documenting:

- Production lines and work centers: How is your shop floor organized? Assembly lines, machining cells, inspection areas?

- Shift patterns: Do you run 1, 2, or 3 shifts? What are the headcount requirements per shift?

- Key roles: Production manager, supervisors, line leaders, operators, technicians, quality inspectors, material handlers

- Critical processes: Which operations are bottlenecks? Which need specialized skills or certifications?

Think in terms of inputs → processes → outputs, as defined in production management frameworks. Where do skills make or break performance? For example, setup skills affect changeover time (process efficiency), quality inspection skills affect defect rates (output quality), and maintenance skills affect equipment uptime (input availability).

Step 2: Define the skills & competencies per role

For each role identified in Step 1, create a full list of required skills. Break these into categories:

Technical skills (operators and technicians):

- Equipment operation (specific machines, tools, systems)

- Quality procedures (inspection methods, testing equipment, documentation)

- Safety and compliance (lockout/tagout, confined space, PPE, hazardous materials handling)

- Maintenance tasks (TPM, preventive maintenance, basic troubleshooting)

- Software/systems (ERP, MES, quality systems)

Managerial/leadership skills (supervisors and managers):

- Production planning and scheduling

- Team leadership and coaching

- Problem-solving and root cause analysis

- Performance management and communication

- Lean/continuous improvement facilitation

Be specific and avoid vague descriptions. Instead of ‘forklift operation,’ specify ‘certified forklift operator (Class IV) for loads up to 5,000 lbs.’ Instead of ‘quality checks,’ specify ‘dimensional inspection using calipers and micrometers per ISO 9001 procedures.’

Reference industry-standard skill lists where possible. For production managers, look at skills from job descriptions and competency frameworks. For technical skills, check equipment manuals, safety requirements, and certification bodies. Many manufacturing skills management platforms provide pre-built skill libraries you can customize.

Step 3: Choose how to document skills, Spreadsheet vs skills matrix software

Once you’ve defined required skills, you need a system to track who has what skills at what level. You have two main options:

Option A: Excel or Google Sheets

Spreadsheet-based skills matrices are a good starting point, especially for small teams or when you’re just getting started with skills management. They’re familiar, flexible, and don’t require any software investment.

However, spreadsheets have serious limits:

- Manual updates are time-consuming and error-prone

- No automated alerts for expiring certifications or training deadlines

- Hard to manage across multiple locations or departments

- Version control issues when multiple people need access

- Tough to integrate with training records, HR systems, or scheduling tools

- A pain during audits when you need instant proof of compliance

For details on skills management software costs and ROI, you can see what investment levels make sense for different organization sizes.

Option B: Skills matrix & Skills management software

Dedicated skills management software solves the pain points of spreadsheets by providing:

- Real-time skills overview accessible to managers, supervisors, and HR

- Automated alerts for expiring certifications, missing qualifications, and training needs

- Multi-user access with role-based permissions

- Integration with training systems, HR databases, and scheduling tools

- Audit-ready reports you can generate instantly

- Visual dashboards showing skills gaps, training completion, and compliance status

For manufacturers with a single production line and fewer than 20 employees, a well-kept spreadsheet might work fine. But as you scale, adding shifts, lines, locations, or complexity, dedicated skills management software becomes essential for keeping things accurate, compliant, and efficient.

Step 4: Assess current production skills

After defining required skills and picking your documentation method, the next step is assessing your current workforce. This baseline assessment shows skill gaps, training priorities, and risks. Use these methods:

Supervisor assessments

Supervisors who work daily with operators are well-positioned to evaluate technical skills through direct observation. Use standardized rating scales (like 1 = needs supervision, 2 = can work independently, 3 = can train others) to keep things consistent across assessors.

Practical tests and sign-offs

For critical equipment or safety-sensitive tasks, run hands-on competency checks. Have operators perform the task under observation and verify they meet standards before signing off on their skills. Document these assessments with dates and assessor names.

Training & certification records

Gather existing training certificates, safety qualifications, licenses, and formal credentials. Note expiration dates where they apply. This gives you your baseline compliance status.

Self-assessment for management skills

For production managers and supervisors, combine self-assessment with manager review. Use structured questionnaires that cover planning, leadership, problem-solving, and communication skills. Self-assessment gives valuable insight into confidence and development needs.

Research from agricultural management studies on skills assessment methods shows that benchmarking is critical: Are your operators truly skilled by industry standards, or just the best you have internally? This perspective helps set appropriate development targets.

Step 5: Build and maintain production skills matrices

With skills defined and assessments complete, you can now build your skills matrices. Whether using spreadsheets or software, the basic structure is the same:

- Rows represent skills or competencies (like ‘CNC Lathe Operation,’ ‘Forklift Certified,’ ‘5S Training’)

- Columns represent employees (individuals or sometimes job positions)

- Cells show proficiency level using numbers (0-4 scale), colors (red/yellow/green), or labels (beginner/proficient/expert)

You can also flip the orientation (employees as rows, skills as columns) if that works better for your workflow or software.

Best practices for skills matrices:

- Group related skills together (all machining skills, all safety skills, all quality skills)

- Highlight critical skills that impact production bottlenecks or safety

- Include certification expiration dates where they apply

- Create separate matrices for different departments, lines, or shifts if needed

- Review and update matrices at least quarterly (more often for fast-changing operations)

For manufacturers using AG5, ready-made production and manufacturing templates speed up this process. Instead of starting from scratch, you pick a template that matches your industry and customize it with your specific equipment, processes, and requirements. This approach makes sure you don’t miss critical skills and follow industry best practices from day one.

Step 6: Use skills data in daily production decisions

The real value of production skills management shows up when you actively use skills data to make better operational decisions:

Staffing shifts and assignments

Before creating shift schedules, check the skills matrix to make sure each line or work center has enough qualified people. For example, if a production line needs at least two people certified on a critical machine, verify that staffing assignments always meet this minimum. Skills matrices help prevent the costly scenario where the production schedule looks fine on paper but lacks the skills needed to execute.

Planning cross-training and succession

Spot single points of failure, skills held by only one person. These represent risk: if that person is out, production suffers. Use the matrix to prioritize cross-training initiatives that spread critical skills across multiple team members. Similarly, identify knowledge held by experienced workers nearing retirement and systematically transfer that knowledge to successors.

Preparing for audits and customer visits

When auditors or customers ask to see proof that operators are qualified for their tasks, your skills matrix gives instant visibility. Modern skills management software can generate compliance reports showing all certifications, expiration dates, and training history in minutes, a process that might take days if records are scattered across filing cabinets and email inboxes. This readiness not only saves time during audits but also shows professionalism and control of your processes.

Assessing production management skills (Managers & leaders)Copied

While much of this guide has focused on technical skills for operators and supervisors, assessing management and leadership skills is just as critical. Production managers directly influence organizational performance through their strategic thinking, decision-making, and people development. However, these skills are harder to evaluate than technical proficiency.

Assessment frameworks for production management should cover:

Strategic planning & resource optimization

Can the manager develop realistic production plans that balance competing constraints? Do they optimize resource allocation or simply react to problems? Look for evidence of proactive planning, what-if scenario analysis, and continuous capacity optimization.

People management & communication

Does the manager develop their team or just delegate tasks? Do they provide clear expectations and constructive feedback? Evaluate through employee engagement scores, retention rates, promotion rates from the department, and 360-degree feedback from direct reports, peers, and superiors.

Data-driven decision-making

Does the manager use data systematically to spot root causes and measure improvement? Or do they rely mainly on intuition and stories? Look at their comfort with key metrics, ability to identify trends, and track record of using data to drive lasting improvements.

Change management and continuous improvement leadership

Can the manager successfully roll out process changes and improvements? Do they build buy-in and keep momentum, or do initiatives stall? Research on production management skills shows that effective change leadership is among the most valuable skills for modern production managers. Assess through the success rate of CI projects, level of team engagement in improvement activities, and ability to overcome resistance to change.

A practical approach combines self-assessment with 360-degree feedback. Have production managers rate themselves against clear competency definitions, then gather input from their manager, peers in other functions, and their direct reports. Compare these perspectives to find development areas.

The idea of benchmarking management skills applies here too. Organizations can compare their production managers’ capabilities to industry standards or high-performing manufacturers. This external perspective helps identify whether gaps are individual development needs or systemic organizational challenges needing different interventions.

Production skills management tools and softwareCopied

As production operations grow, most manufacturers eventually outgrow spreadsheets and need dedicated software. Understanding the landscape of manufacturing skills management platforms helps you evaluate options and pick the right solution for your needs.

Category overview: Manufacturing skills management platforms

Manufacturing skills management platforms focus on frontline workforce capabilities: operators, technicians, supervisors, and production managers. These platforms typically emphasize:

- Skills matrices and competency tracking for technical roles

- Certification management and compliance tracking

- Training history and development planning

- Skills-based staffing and scheduling

- Audit-ready reporting and documentation

Examples include Kahuna Workforce Solutions, which positions itself around validated frontline skills data, staffing optimization, and compliance. Their approach helps manufacturers make sure the right qualified people are in the right positions at the right time.

AG5: Skills management built for manufacturing

AG5 specializes in skills matrix software and training matrix software designed specifically for manufacturing environments. Key capabilities include:

Pre-built manufacturing templates

Rather than starting from scratch, manufacturers can use hundreds of industry-specific templates covering production operations, tool and die, TPM (Total Productive Maintenance), safety protocols, quality systems, and more. These templates are based on best practices and can be customized to match your specific equipment, processes, and requirements.

Real-time skills overview

AG5 provides instant visibility into production skills, qualifications, and certifications across single or multiple facilities. Production managers, supervisors, and HR teams can access up-to-date information anytime, eliminating the version control and data accuracy problems built into spreadsheet-based systems.

Automated alerts and notifications

The system automatically flags expiring certifications, overdue training, and missing qualifications, allowing managers to address issues proactively rather than discovering gaps during audits or when production needs pop up.

Audit-ready reporting

Generate compliance reports instantly showing certifications, training completion, and skills coverage. This capability dramatically reduces the admin burden of audits and shows process control to customers and regulatory bodies.

Example: Production skills management in a manufacturing plantCopied

To make these concepts concrete, let’s walk through a realistic implementation scenario:

The situation

A mid-sized automotive components manufacturer operates three production lines across two shifts. The plant employs:

- 1 Production Manager

- 3 Line Supervisors (one per line)

- 24 Production Operators

- 4 Maintenance Technicians

- 2 Quality Inspectors

The plant had been tracking skills informally, supervisors knew who could run what equipment, but there was no centralized system. When a major customer audit was announced, the production manager realized they couldn’t quickly show operator qualifications.

The implementation

Step 1: Template selection

The production manager selected AG5’s manufacturing skills matrix template, which included relevant skill categories for their operations:

- Equipment operation (CNC machining centers, automated assembly, inspection equipment)

- Safety certifications (forklift, lockout/tagout, confined space)

- Quality procedures (dimensional inspection, first article inspection, PPAP documentation)

- TPM activities (autonomous maintenance, cleaning, basic troubleshooting)

They customized the template by adding their specific machine models and internal procedures.

Step 2: Data collection

HR imported employee rosters and existing training records from their learning management system. Supervisors ran skill assessments for each operator on their line, rating proficiency on a 1-4 scale (1 = trainee, 2 = competent under supervision, 3 = fully competent, 4 = expert/trainer).

Step 3: Matrix updates

Supervisors used AG5’s mobile app to update matrices directly from the shop floor, cutting out the need to return to a desk computer. They marked current proficiency levels and added notes about planned training or recertification needs.

Step 4: Operational use

The production manager now uses the skills matrix weekly when building shift rosters, making sure each line has at least two operators qualified on critical equipment. When planning vacation schedules, they check the matrix to avoid situations where the only person certified on a machine would be out.

The results

Within three months of rolling out the system:

- The customer audit was completed successfully with instant access to all operator qualifications

- Cross-training increased by 35% as the matrix clearly showed single points of failure

- Equipment downtime due to ‘no qualified operator available’ dropped to zero

- Expired certifications decreased by 80% thanks to automated renewal alerts

Most importantly, the production manager reported spending less time firefighting staffing issues and more time on strategic improvements like capacity optimization and continuous improvement initiatives.

Getting started with production skills management in AG5Copied

If you’re ready to move beyond spreadsheets and roll out systematic production skills management, AG5 provides a proven path forward:

The pain you’re solving

Excel-based skills tracking and ad-hoc approaches can’t keep pace with:

- Growing production complexity and headcount

- Increasingly strict audit requirements

- High turnover requiring systematic onboarding and cross-training

- Multiple shifts, lines, or facilities that need coordinated skills management

What AG5 provides

- Single source of truth. All production skills, certifications, and training records in one system accessible to authorized users

- Ready-made templates. Production and manufacturing templates mean you don’t start from scratch, customize industry best practices to your operation

- Real-time, audit-ready matrices. Generate compliance reports instantly, whether for internal reviews or customer audits

- Scalability. Start with one line or department and expand across your entire operation as needed

Next steps

Download AG5’s free production skills matrix template to see how a structured approach transforms skills data from static spreadsheets into a live production skills management system. The template gives you a starting point you can use right away. When you’re ready to scale, AG5’s full platform provides the automation, integrations, and enterprise features that growing manufacturers need.

Final thoughtsCopied

Production skills management is no longer optional for competitive manufacturing operations. The challenges of maintaining quality, meeting delivery commitments, ensuring safety compliance, and passing audits all depend fundamentally on having the right skills in the right roles at the right time.

This guide has covered the essential elements of production skills management:

- Understanding production roles from managers to operators and their distinct skill requirements

- Identifying the hard and soft skills that matter most in today’s production environments

- Building systematic skills management systems using matrices and software

- Assessing both technical and management capabilities

- Rolling out practical tools that scale from spreadsheets to enterprise software

The manufacturers that excel don’t just have skilled people, they have systematic processes for defining, developing, and deploying those skills strategically. They know exactly what capabilities they have, where the gaps are, and what training investments will deliver the highest returns.

Whether you’re starting with a basic spreadsheet or rolling out enterprise skills management software like AG5, the key is to start systematically documenting and managing production skills today. Every day without visibility into your skills inventory is a day you’re operating with unnecessary risk and missed opportunity.

Your production skills are too valuable to manage informally. Give them the systematic attention they deserve, and watch your operational performance improve as a result.

FAQs Copied

-

What is production skills management?

-

What is the difference between a skills matrix and production skills management?

-

How do I start building a production skills matrix?

-

What skills are most important for production managers?

-

Should I use Excel or skills management software?

-

How often should I update production skills matrices?

-

What is the best way to assess operator skills?

-

How can production skills management help with audits?

-

What is skills benchmarking and why does it matter?

-

How do I handle skills management across multiple shifts or facilities?

Author Copied

Revisions Copied

Written by: Rick van Echtelt

Copy edited by: Adam Kohut