Manufacturing skills matrix template

You can use this free manufacturing skills matrix to identify and track the proficiency levels of employees in machine operation, equipment maintenance, quality control, and safety protocols.

Download your free template here

Overview Copied

With our free manufacturing skills matrix template, you will receive a clear overview of the skills that are present in your organization, as well as those that are missing. Using this information, you can develop and implement a plan to ensure that your employees’ skills are up to date, comprehensive, compliant, and ready for the future.

Production line operation

- Assembly line operation

- Machine setup and calibration

- Preventive maintenance

- Quality control inspections

- Troubleshooting and repair

- Inventory management

Specific production line tasks

- Carpet punching

- Latch table assembly

- Glue robot operation

- Assembly PDI (pre-delivery inspection)

- Roll compression

Trim and assembly system

- TAS station build operations

- TAS station hogring operations

- TAS station bezel pull

- TAS station plastics fit

- TAS station seat assembly

Benefits Copied

Using a skills matrix template can benefit your manufacturing teams in various ways. Among them:

- Equipment proficiency and maintenance. Easily identify employees’ expertise in operating and maintaining manufacturing-industry machinery, minimizing downtime and reducing maintenance costs.

- Cross-training for flexibility. Discover cross-training opportunities, so certain employees can seamlessly shift between roles or production lines.

- Health and safety compliance. Maintain a safe working environment by ensuring employees are compliant with manufacturing safety standards.

- Specialized process knowledge. Track employees’ knowledge of specific manufacturing processes, ensuring tasks are assigned to those with the expertise.

- Regulatory compliance. Ensure your workforce remains compliant with industry standards, reducing the risk of issues that could impact product quality and audit results.

Download the free Excel Manufacturing skills matrix template Copied

We also have a free Excel template available that you can download if you are not ready to get started with AG5. To download it, please complete this form here.

Looking for alternatives to Excel for your skills matrix templates? Copied

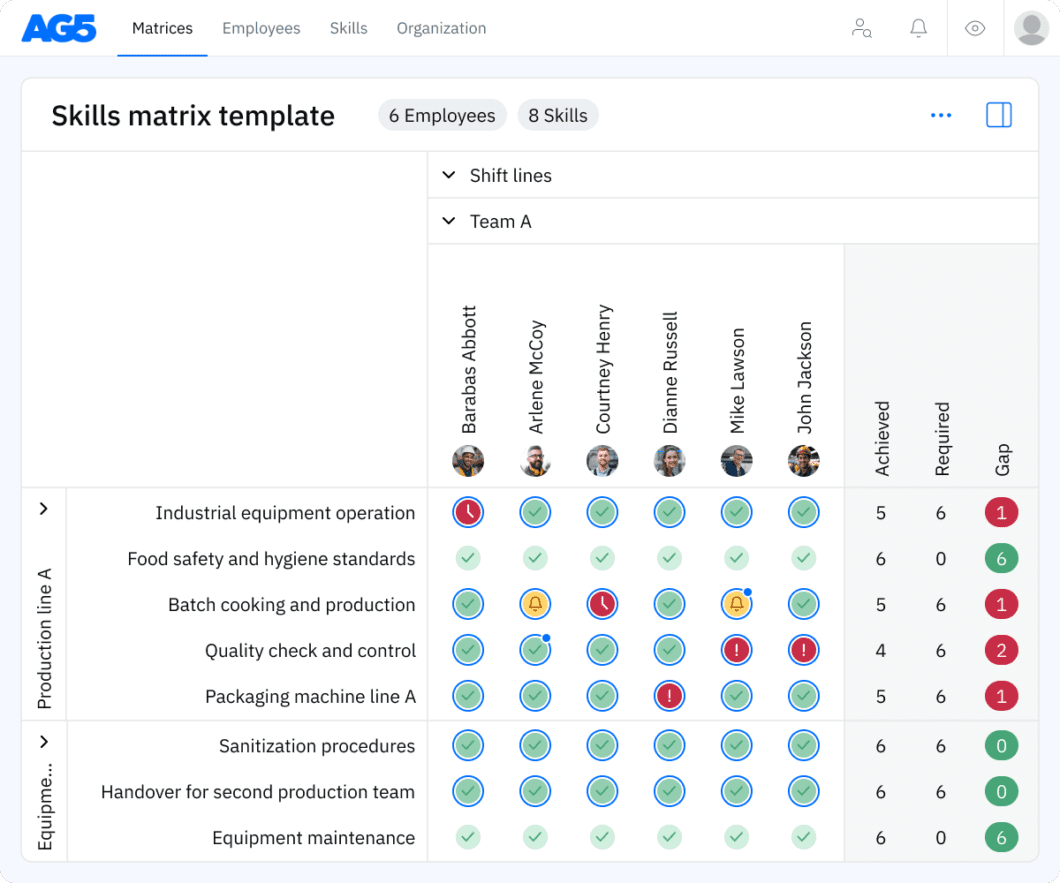

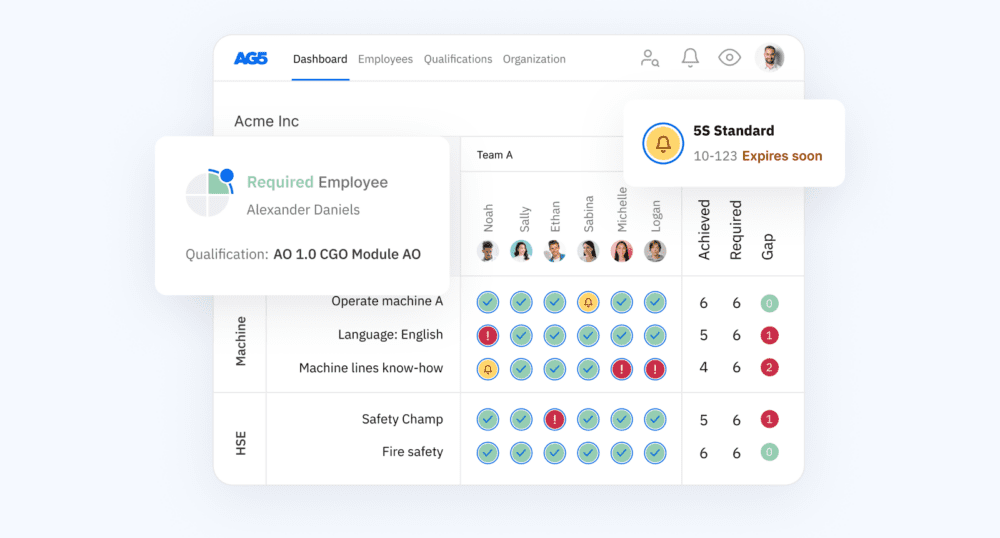

AG5’s skills management software enables you to visualize and close skills gaps across your organization – no need for complicated Excel spreadsheets. You’ll use intuitive skills matrices that bring together skills data and job requirements – and are always up to date.

Customizing a skills matrix Copied

The scope of this manufacturing skills matrix can be as large or small as you choose. For example, it could cover your entire manufacturing operations – or only those employees or teams involved with quality control.

To customize a skills matrix to your needs, you should:

- Define focus. Clarify if the skills matrix pertains to an entire department or specific roles within it.

- Identify key skills. List essential competencies for each role or area of operation.

- Establish proficiency levels. Define skill proficiency levels, aligning them with job requirements.

- Set evaluation criteria. Create a clear evaluation process, considering on-the-job performance and training qualifications.

- Regularly review and update. Ensure regular reviews to adapt to evolving roles, technologies, and organizational goals.

Author Copied

Revisions Copied

Written by: Rick van Echtelt

Copy edited by: Adam Kohut

Tired of managing skills in Excel?

Say goodbye to Excel matrices. Start using AG5’s plug and play skill matrix software.

Recognized by G2 for Excellence in Skills Management