Lean manufacturing skills matrix template

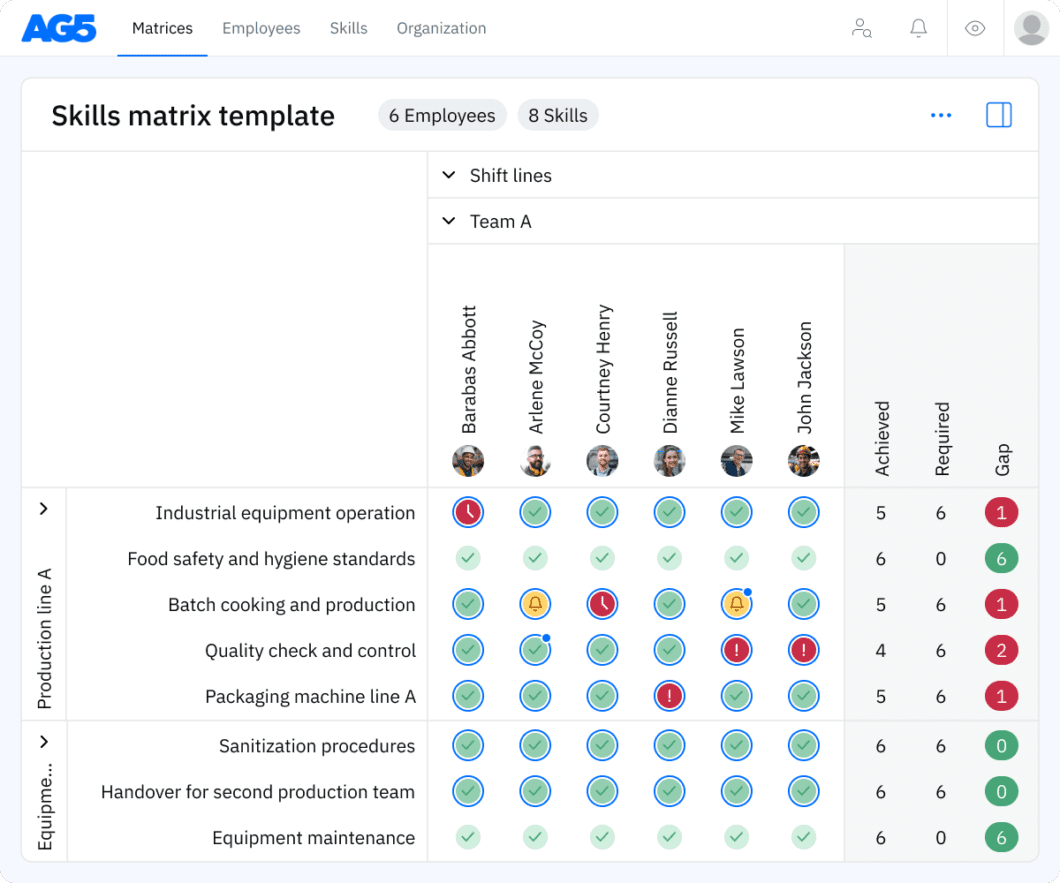

A skills matrix template is a tool lean manufacturing organizations can use to effectively manage and assess their skills and knowledge.

Download your free template here

Overview Copied

With our free lean manufacturing skills matrix template, you will receive a clear overview of the skills that are present in your organization, as well as those that are missing. Using this information, you can develop and implement a plan to ensure that your employees’ skills are up to date, comprehensive, compliant, and ready for the future.

Lean principles and concepts

- Understanding of the 5S methodology (Sort, Set in order, Shine, Standardize, Sustain)

- Knowledge of Kaizen for continuous improvement

- Identifying and eliminating waste (Muda) in manufacturing processes

- Implementing value stream mapping to identify inefficiencies

- Understanding of pull systems and just-in-time (JIT) manufacturing

Process improvement methodologies

- Implementing Six Sigma methodologies for process optimization

- Conducting root cause analysis (RCA) for identifying process issues

- Using PDCA (Plan-Do-Check-Act) cycle for continuous process improvement

- Applying problem-solving techniques such as A3 reporting and 8D methodology

- Developing and managing cross-functional improvement teams for process enhancements

Lean tools and techniques

- Implementing Kanban systems for inventory control and flow

- Utilizing SMED (Single-Minute Exchange of Die) for reducing setup times

- Applying takt time and cycle time analysis for production efficiency

- Using Total Productive Maintenance (TPM) to minimize equipment downtime

- Conducting process audits and Gemba walks to identify improvement opportunities

Value stream mapping and analysis

- Creating current and future state value stream maps to identify bottlenecks

- Analyzing lead times, cycle times, and takt times in the value stream

- Identifying areas of overproduction, excess inventory, and other waste sources

- Developing action plans to streamline operations based on value stream analysis

- Collaborating with cross-functional teams to implement value stream improvements

Benefits Copied

Skills management software for manufacturing can help organizations identify skill gaps and develop targeted training programs to improve lean manufacturing practices, ultimately improving product quality and reducing waste.

Download the free Excel Lean manufacturing skills matrix template Copied

We also have a free Excel template available that you can download if you are not ready to get started with AG5. To download it, please complete this form here.

Author Copied

Revisions Copied

Tired of managing skills in Excel?

Say goodbye to Excel matrices. Start using AG5’s plug and play skill matrix software.

Recognized by G2 for Excellence in Skills Management