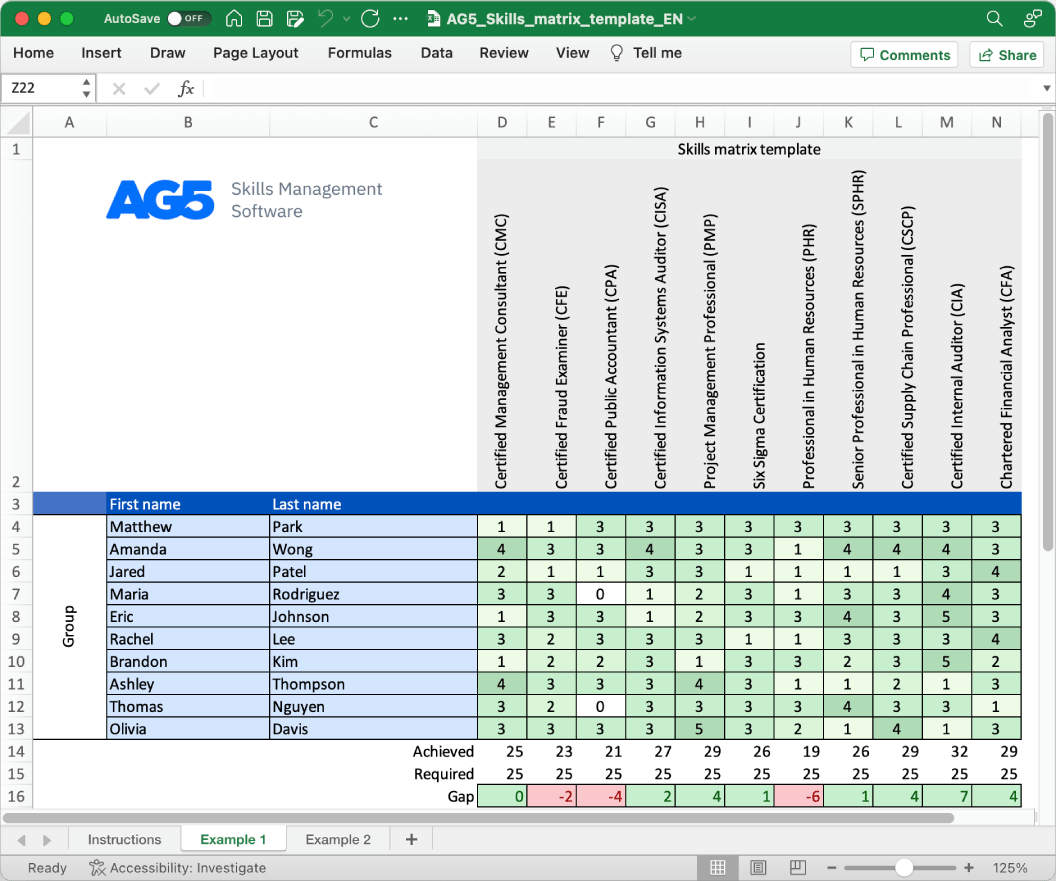

Equipment troubleshooting skills matrix template

A skills matrix template is a tool teams can use to assess their equipment troubleshooting skills and knowledge

Download your free template here

Overview Copied

With our free equipment troubleshooting skills matrix template, you will receive a clear overview of the skills that are present in your organization, as well as those that are missing. Using this information, you can develop and implement a plan to ensure that your employees’ skills are up to date, comprehensive, compliant, and ready for the future.

- Certified Equipment Specialist (CES)

- Certified Equipment Technician (CET)

- Certified Equipment Maintenance Technician (CEMT)

- Certified Equipment Repair Specialist (CERS)

- Certified Equipment Troubleshooter (CETR)

- Certified Equipment Reliability Engineer (CERE)

- Certified Equipment Failure Analysis Professional (CEFA)

- Certified Equipment Diagnostician (CED)

- Certified Equipment Calibration Technician (CECT)

- Certified Equipment Inspection Specialist (CEIS)

- Certified Equipment Service Technician (CEST)

- Certified Equipment Performance Analyst (CEPA)

- Certified Equipment Optimization Expert (CEOE)

- Certified Equipment Reliability Specialist (CERS)

- Certified Equipment Reliability Manager (CERM)

- Certified Equipment Reliability Auditor (CERA)

- Certified Equipment Reliability Trainer (CERT)

- Certified Equipment Troubleshooting Supervisor (CETS)

- Certified Equipment Troubleshooting Consultant (CETC)

- Certified Equipment Troubleshooting Analyst (CETA)

Benefits Copied

Skills management software for manufacturers is important in equipment troubleshooting to track and manage the skills of individuals responsible for identifying and resolving equipment issues. It ensures that professionals possess technical knowledge, problem-solving skills, and proficiency in using diagnostic tools for efficient equipment troubleshooting.

Author Copied

Revisions Copied

Tired of managing skills in Excel?

Say goodbye to Excel matrices. Start using AG5’s plug and play skill matrix software.

Recognized by G2 for Excellence in Skills Management