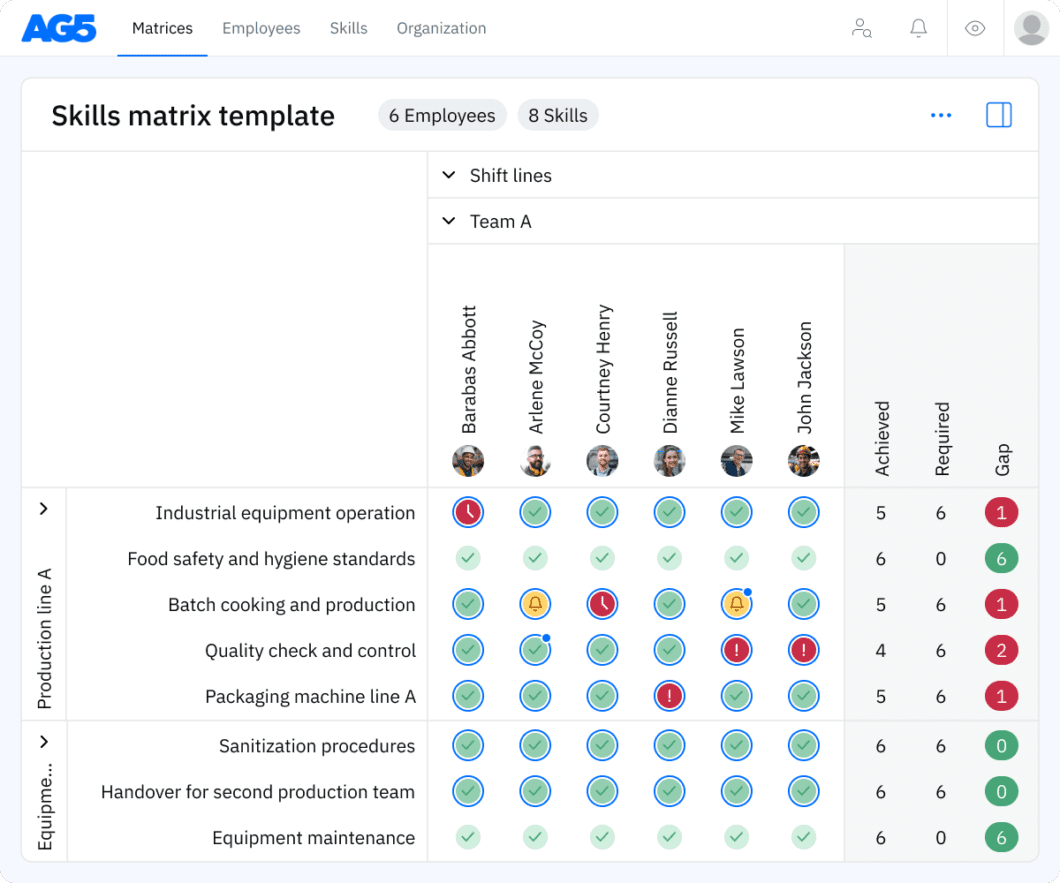

Maintenance skills matrix template

A skills matrix template is a tool that organizations can use to effectively manage and assess the skills and certification statuses of individual employees or teams. For example, you can use this maintenance skills matrix to assess technicians' proficiency in tasks such as equipment troubleshooting, preventive maintenance, and machine repair.

Download your free template here

Overview Copied

With our free maintenance skills matrix template, you will gain a comprehensive overview of the skills present within your organization and identify any skill gaps that may exist. Using this information, you can develop and implement a strategic plan to ensure that your employees’ maintenance skills are up to date, comprehensive, compliant, and ready for the future.

Repair procedures

- Preventive maintenance

- Component replacement techniques

- Troubleshooting and repair

- Sensors and actuators

- Hydraulics and pneumatics

- Electrical systems maintenance

- Calibration and testing

Production line maintenance

- 1.1 B7X CNC machine operation

- 1.2 B7X Milling and turning

- 1.3 B7X Machine setup and calibration

- 1.4 B7X Precision measurement

- 1.5 B7X Tool selection and maintenance

- 1.6 B7X Production monitoring

Certifications

- Certified Maintenance and Reliability Professional (CMRP)

- Certified Maintenance Manager (CMM)

- Certified Maintenance Technician (CMT)

- Certified Reliability Leader (CRL)

- Certified Maintenance Planning and Scheduling Professional

Benefits Copied

Using a skills matrix template can benefit your maintenance team in various ways. Among them:

- Efficient response to equipment failures. Minimize downtime by quickly assigning skilled personnel to address equipment failures, ensuring swift resolution and minimal impact on production.

- Enhanced cross-training opportunities. Identify and capitalize on opportunities to cross-train personnel, fostering a versatile workforce capable of handling diverse maintenance tasks efficiently.

- Compliance with industry standards. Ensure adherence to industry regulations by mapping team certifications and competencies, promoting a compliant and safe manufacturing environment.

- Optimized preventive maintenance planning. Plan preventive maintenance schedules effectively based on team skills, ensuring tasks align with available expertise for efficient and proactive equipment care.

- Continuous improvement initiatives. Foster a culture of improvement by regularly updating the skills matrix, tracking development, and aligning team capabilities with evolving manufacturing technologies.

Download the free Excel Maintenance skills matrix template Copied

We also have a free Excel template available that you can download if you are not ready to get started with AG5. To download it, please complete this form here.

Frequently asked question Copied

-

What are the benefits of using a maintenance skills matrix?

-

Is the maintenance skills matrix free to download?

-

How do I use a maintenance skills matrix?

-

What if I want to take my skills management to the next level?

Author Copied

Revisions Copied

Tired of managing skills in Excel?

Say goodbye to Excel matrices. Start using AG5’s plug and play skill matrix software.

Recognized by G2 for Excellence in Skills Management