Industry 5.0 manufacturing

In this article, we explain Industry 5.0 manufacturing, focusing on human-robot collaboration, sustainability, and integrating emerging technologies into manufacturing processes.

The endorsement of an Industry 5.0 manufacturing approach by the European Commission has far-reaching consequences for the future of the EU’s industrial strategy. It requires a new orientation toward industry performance, a new design for business models, value and supply chains, and a new purpose for digital transformation.

These changes demand renewed approaches to policymaking in partnership with business and industry, as well as new capabilities and approaches to research and innovation. To overcome these challenges, all levels of government must work together to create international standards that will set the foundation for Industry 5.0.

In this article, we will closely examine the concept of Industry 5.0, including what it entails and how it differs from previous industrial revolutions. We will also discuss the core elements of Industry 5.0 manufacturing and how companies can prevail in the next industrial revolution. Now, let’s dive in!

What is Industry 5.0 manufacturing?Copied

Industry 5.0 is the future of work, referring to people utilizing robots and intelligent machines to drive productivity and economic growth. Workers are set to benefit from the assistance of robots with cutting-edge technologies like the Internet of Things (IoT) and big data, making work easier and prioritizing safety and collaboration.

Industry 5.0 will empower workers and maximize efficiency. Central to this philosophy is the concept of the “cobot” – a humanoid robot designed to work alongside human employees in all aspects of the production process.

The term “Industry 5.0” was coined in Germany at the CeBIT 2017 trade fair in Hannover. At the event, Japan presented its vision for the future of industrial automation, robotics, and intelligent manufacturing. The Japanese invention, called Society 5.0, gave birth to the concept of Industry 5.0 as an evolution of the original idea with an enhanced role of humans.

The EU commission’s vision for Industry 5.0 goes beyond the traditional focus on technology or economic growth. This new approach shifts the focus to human progress and well-being.

Industry 5.0 is essential to reducing and shifting consumption to new forms of sustainable, circular, and regenerative economic value creation. Rather than representing a technological leap forward, Industry 5.0 builds on the existing Industry 4.0 approach, providing a broader context for the technological transformation of industrial production. The goal is to benefit people, the planet, and prosperity, rather than simply value extraction for shareholders. This will result in equitable prosperity for all.

Why industry 5.0?Copied

The European Union is amidst a so-called “twin transition.” This paper proposes an alternative approach to connecting digital transformation with sustainability and climate action.

In Industry 4.0, computers are already connected more than ever before. Machines, devices, and sensors communicate to share data and make decisions. Production lines can run without interruption, and orders can be filled automatically – without human input.

The benefits of these technological advances are clear. However, some challenges still need to be addressed before Industry 4.0 can reach its full potential, such as the high initial investment costs associated with these technologies.

Another challenge is the lack of skilled workers who can operate and maintain these complex systems. The biggest challenge, however, is the effect of automation on jobs.

In the US alone, up to 73 million jobs may be eliminated by 2030, according to a McKinsey report. This led to Industry 5.0’s more human-centric approach, linking the digital transformation of industry more closely to social developments.

By creating new jobs and retraining workers for future employment, Industry 5.0 can help mitigate the adverse effects of automation and ensure everyone can benefit from the industrial revolution.

Europe’s 2030 goals need a new framework

The Green Deal is a unique opportunity for the EU to redefine its industrial policy. The 10-year, €1 trillion investment plan can potentially put Europe on the path to climate neutrality by 2030, as the latest scientific evidence suggests, creating a new economic paradigm.

The industry is facing a paradigm shift, which brings with it a new set of challenges and opportunities – one of the most significant of which involves linking technologies more closely to the environment.

The goal is to create a more sustainable, resilient, and human-centric industry that is better able to meet the needs of 21st-century society.

Several factors must be taken into account to achieve this:

- Making technologies more energy-efficient and environmentally friendly

- Ensuring that new technologies are accessible to all members of society, not just those who can afford them

- Creating an industry that is more adaptive and responsive to change to keep up with the world’s evolving needs

With these challenges in mind, it is clear that the industry is at a crossroads. The decisions we make now will determine the course of our industry for years to come. Therefore, we must make the right choices to create an industry that is fit for the future.

Industry 4.0 manufacturing vs. Industry 5.0 manufacturingCopied

- Industry 4.0 is all about efficiency through digital connectivity and artificial intelligence (AI). This refers to the emergence of physical objects that are connected to the internet and can communicate with each other. This is ultimately directed at minimizing costs and maximizing profit for shareholders. However, Industry 4.0 is not focused on the design and performance dimensions essential for systemic transformation regarding environmental, climate, and social impact. As a result, Industry 4.0 could potentially harm the environment and society.

- Industry 5.0 ensures a framework for initiatives that combine competitiveness with sustainability, and seems to be a game-changer for how we do business. It emphasizes the importance of alternative modes of governance when it comes to sustainability and resilience, and empowers workers through digital devices. This combination of factors will help build transition pathways toward environmentally sustainable technology services, while expanding corporations’ responsibility to their entire value chains. In Industry 5.0, indicators will also be introduced that show the progress achieved on the path to well-being, resilience, and overall sustainability for each industrial ecosystem.

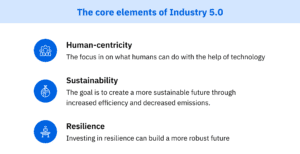

The core elements of Industry 5.0Copied

Industry 5.0 is not a radical departure from Industry 4.0, but a continuation of the trend towards increased automation and connection. The three core elements of Industry 5.0 are human-centricity, sustainability, and resilience. These are all areas in which Industry 4.0 has made significant advances, and which will continue to be important in the future. To achieve these goals, Industry 5.0 will build on the successes of Industry 4.0 while incorporating new technologies and ideas.

Industry 4.0 technologies affect the economy, environment, and society equally. As human-centricity, sustainability, and resilience become more important in the industry, ongoing digitization initiatives promise to be all the more successful.

Human-centricity

In Industry 4.0, the focus was on what technology could do to improve production processes. This led to the development of automated solutions that helped speed up and streamline production. However, these solutions often came at the expense of human workers, who were replaced by machines. In Industry 5.0, the focus is on what humans can do with the help of technology. This shift in thinking has led to the development of solutions designed to augment rather than replace human workers. For example, wearable technologies and augmented reality are being used to provide workers with real-time data and instructions, allowing them to work more efficiently. As Industry 5.0 manufacturing evolves, the goal is to create a symbiotic relationship between humans and machines, in which each can complement and enhance the other.

Sustainability

The goal of Industry 5.0 manufacturing is to create a more sustainable future through increased efficiency and decreased emissions. One way to achieve this goal is through the circular economy, which aims to find solutions for resource consumption. The EU has already set a course for increasing the quality and percentage of secondary raw materials (i.e., recycled goods). Another way to achieve sustainability is through improved energy efficiency. The EU is working to decrease emissions by implementing regulations requiring industry to become more energy efficient. As we move into Industry 5.0, we must keep sustainability at the forefront of our minds.

Resilience

Resilience is often thought of as a personal trait that enables us to recover from adversity. However, the term is also used concerning supply chains, which are increasingly vulnerable to disruptions. The Covid-19 pandemic has shown how easily global supply chains can be disrupted, with often devastating consequences. In response, the EU Commission has set up the Recovery and Resilience Facility to support member states in reforming and investing in more resilient solutions. The industry has many tools to respond to disruptions, such as big data and predictive maintenance. Investing in resilience can build a more robust future.

Copied

Copied

How to thrive in the next industrial revolutionCopied

The next industrial revolution will likely be even more disruptive than the previous one. This time, the changes will be driven by artificial intelligence, robotics, and other technologies that are developing rapidly. As these technologies mature, they will profoundly impact every aspect of society, from how we work and live, to the structure of our economy.

Here are five tips that will enable you to prevail in the next industrial revolution:

- Understand and utilize automation and robotics and how they are used to enhance the production process. While it may initially seem counterintuitive, embracing automation technologies can help free up resources, so you can focus on other areas of your business, such as customer service or product innovation – both essential components of success in any industry. Consider which tasks are the most time-consuming or tedious; if they can be automated by robotics or machine learning (ML) algorithms, take steps to automate them. This will help keep costs down while allowing you to focus on what matters most – growing your business.

- Understand machine learning techniques and models and how to apply them. Business owners must understand how machine learning models work and how they can be applied effectively within their industry or sector. Machine learning models make it possible to automate tasks previously done manually, making them more efficient and cost-effective. Additionally, understanding machine learning will allow companies to develop more accurate predictions about customer behavior or market trends that can be used to better inform business decisions.

- Invest in data and AI technology. Doing so will give your organization an edge over industry competitors that are not taking advantage of these tools. This means investing in cloud computing systems that provide up-to-date data insights, and leveraging AI algorithms to create automated processes that save time and money, while helping optimize operations more accurately than ever.

- Reimagine job descriptions and hire new talent with relevant skill sets. As technology advances, roles within an organization must also change accordingly. Companies must create new roles or adjust existing ones to ensure that their employees have the necessary skills to keep up with Industry 5.0’s fast pace. A few positions that may become more prominent include Chief Robotics Officer (CRO) or senior AI strategist, as well as roles related to using AI/ML, such as data analysts or data scientists who focus on leveraging AI/ML tools for predictive analytics, or optimizing customer experience through personalization solutions. Additionally, look for talent with skill sets like “data scientist” or “robotics engineer,” which will be more pertinent as our reliance on machines increases.

- Strategically leverage human capital resources. Despite the prevalence of robots and AI in Industry 5.0 manufacturing, you should stay focused on human resources. Strive to combine your staff’s skill sets with AI and automation to provide more added value than your competitors. Leaders should invest in software such as skills management tools to help their HR team better manage employees’ skill sets and ensure they are utilized effectively within an organization’s workflow. Skills management software enables employers to quickly identify areas in which additional training or retraining may be necessary

The next industrial revolution will likely bring about unprecedented changes in our world. Those leaders who can adapt and innovate will survive and thrive.

AG5 software and the next industrial revolutionCopied

As the world moves into Industry 5.0, it’s more important than ever to have a skills management solution that can keep up with the latest changes. AG5 was designed for agility and adaptability, with a modular design that makes adding new features and functionality accessible. Additionally, our organization includes a team of experts who are always current on the latest trends and technologies. You can schedule a free demo to learn more about how AG5 software can help your company survive and thrive in the next industrial revolution.

Schedule your free demo today!