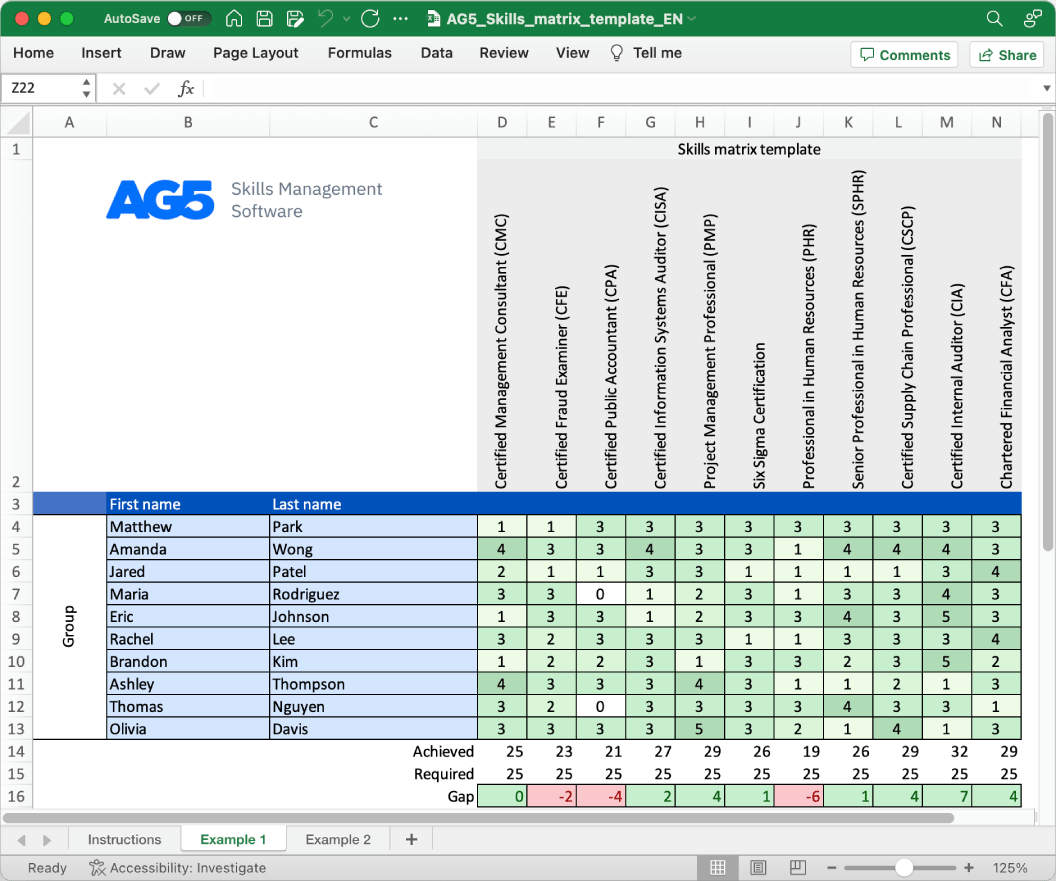

Rotational molding skills matrix template

A skills matrix template is a tool that organizations can use to effectively manage and assess the skills and certification statuses of individual employees or teams.

Download your free template here

Overview Copied

You can use this rotational molding skills matrix for operators, engineers, and technicians who handle tasks like mold design, machine setup, material selection, process troubleshooting, and quality control.

Design & Engineering

- Mold design

- Product design for rotomolding

- Material selection

- Wall thickness optimization

- CAD modeling

- SolidWorks Certification

- Autodesk Certification

Production & Operations

- Machine setup

- Mold loading and unloading

- Temperature control

- Process troubleshooting

- Quality inspection

- OSHA Safety Certification

- Lean Manufacturing Certification

Materials & Processes

- Polymer science basics

- Resin flow behavior

- Material drying

- Color and additive mixing

- Regrind use and limits

- ASME Geometric Dimensioning and Tolerancing (GD&T) certification

Quality & Compliance

- Dimensional inspection

- Defect identification

- Root cause analysis

- Process documentation

- Final product testing

- ISO 9001 Internal Auditor

- Six Sigma Green Belt

Benefits Copied

Using a rotational molding skills matrix template can benefit your teams in various ways. Among them:

- Targeted training for molding process expertise. You can use this skills matrix to identify gaps in specialized areas like mold design and resin handling, so you can provide targeted training that helps employees develop the expertise to handle the intricacies of the rotational molding process

- Enhanced machine and equipment management. By tracking skills related to machine setup and maintenance, you can ensure that only experienced operators handle critical equipment

- Improved product consistency and quality control. Using a skills matrix to monitor quality control skills, such as defect identification and dimensional inspection, helps ensure that employees are consistently able to identify and correct issues early

How can I customize my rotational molding skills matrix to fit a specific team? Copied

The scope of a rotational molding skills matrix can be as large or small as you choose. For example, it could cover your entire organization – or only those tasked with mold production and molding operations.

To customize a skills matrix to your needs, you should:

- Define focus. Clarify if the skills matrix pertains to an entire department or specific roles within it

- Identify key skills. List essential competencies for each role or area of operation

- Establish proficiency levels. Define skill proficiency levels, aligning them with job requirements

- Set evaluation criteria. Create a clear evaluation process, considering on-the-job performance and training qualifications

- Regularly review and update. Ensure regular reviews to adapt to evolving roles, technologies, and organizational goals

Do you require a skill or certification that is not included in the above list? No problem! You can easily add additional certifications yourself to customize the skills matrix to your organization’s needs. You can also add your own employees and how they score against each certification.

Not sure what scoring system to use? Check out our “Ultimate Guide to Creating an Excel Skills Matrix.”

Looking for alternatives to Excel for your skills matrix templates? Copied

AG5’s skills management software enables you to visualize and close skills gaps across your organization – no need for complicated Excel spreadsheets. You’ll use intuitive skills matrices that bring together skills data and job requirements – and are always up to date.

FAQs Copied

-

What are the benefits of using a rotational molding skills matrix?

-

Is this rotational molding skills matrix free to download?

-

How do I use a rotational molding skills matrix?

-

What if I want to take my skills management to the next level?

Author Copied

Revisions Copied

Tired of managing skills in Excel?

Say goodbye to Excel matrices. Start using AG5’s plug and play skill matrix software.

Recognized by G2 for Excellence in Skills Management