Plastics skills matrix template

A skills matrix template is a tool that can be used in the plastics industry to effectively manage and assess the skills and knowledge of individual employees or teams.

Download your free template here

Overview Copied

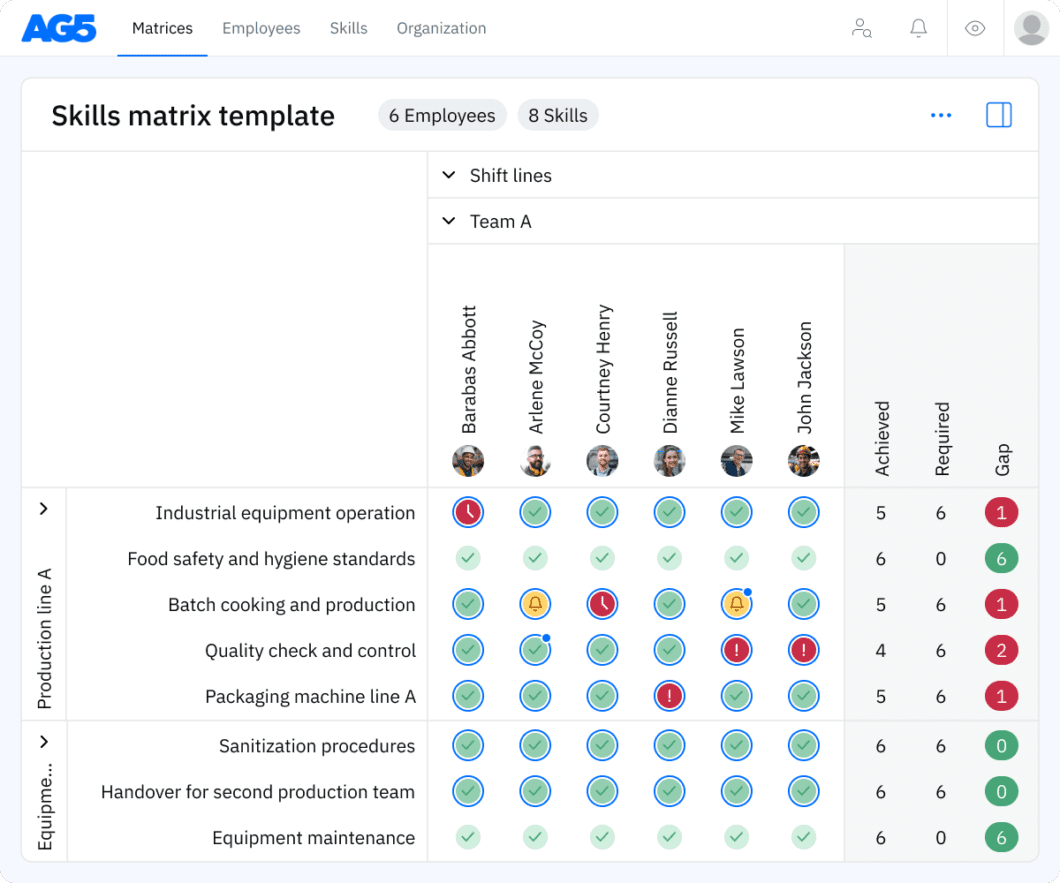

With our free plastics manufacturing skills matrix template, you will receive a clear overview of the skills that are present in your organization, as well as those that are missing. Using this information, you can develop and implement a plan to ensure that your employees’ skills are up to date, comprehensive, compliant, and ready for the future.

Plastic molding and forming processes

- Injection molding operation and setup

- Blow molding techniques and machine operation

- Thermoforming process and equipment operation

- Extrusion molding operation and process control

- Understanding of mold design and maintenance

Material handling and preparation

- Handling and mixing plastic resins and additives

- Operating material feeding and drying systems

- Understanding material properties and selection

- Preparing materials for different molding processes

- Monitoring and maintaining material quality and consistency

Machine maintenance and troubleshooting

- Performing routine maintenance on molding machines

- Troubleshooting common machine issues and malfunctions

- Understanding hydraulic, pneumatic, and electrical systems in machines

- Conducting mold changeovers and machine setup adjustments

- Implementing preventive maintenance schedules and practices

Process optimization and efficiency

- Implementing lean manufacturing principles in plastic production

- Optimizing cycle times and reducing waste in molding processes

- Conducting root cause analysis for process inefficiencies

- Monitoring key performance indicators (KPIs) for production

- Applying continuous improvement techniques (e.g., Kaizen) to manufacturing

Benefits Copied

Skills management software can benefit the plastics industry by tracking and managing employee skillsets, facilitating targeted training and development, ensuring compliance with regulatory requirements, and improving productivity and efficiency in the workplace.

Download the free Excel Plastics skills matrix template Copied

We also have a free Excel template available that you can download if you are not ready to get started with AG5. To download it, please complete this form here.

Author Copied

Revisions Copied

Tired of managing skills in Excel?

Say goodbye to Excel matrices. Start using AG5’s plug and play skill matrix software.

Recognized by G2 for Excellence in Skills Management