Corrective and preventive maintenance planning skills matrix template

A skills matrix template is a tool teams can use to assess their corrective and preventive maintenance skills and knowledge

Download your free template here

Overview Copied

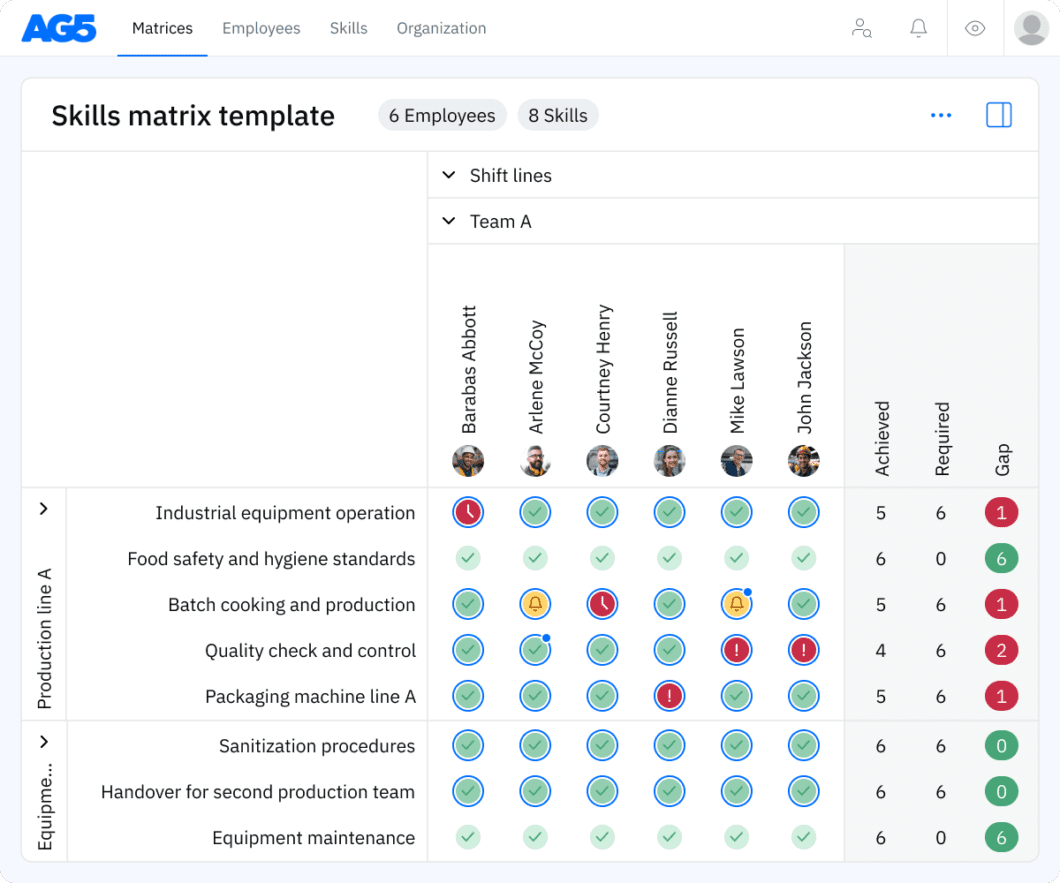

With our free corrective and preventive maintenance skills matrix template, you will receive a clear overview of the skills that are present in your organization, as well as those that are missing. Using this information, you can develop and implement a plan to ensure that your employees’ skills are up to date, comprehensive, compliant, and ready for the future.

Preventive maintenance scheduling and planning

- Developing preventive maintenance schedules for manufacturing equipment

- Monitoring equipment performance to determine maintenance intervals

- Implementing computerized maintenance management systems (CMMS) for tracking

- Coordinating maintenance activities to minimize production downtime

- Prioritizing maintenance tasks based on criticality and equipment usage

Corrective maintenance execution and troubleshooting

- Diagnosing equipment failures and identifying root causes

- Performing repairs on malfunctioning machinery and restoring functionality

- Using diagnostic tools and equipment for effective troubleshooting

- Implementing immediate corrective actions to minimize production disruptions

- Documenting all corrective maintenance activities for future reference

Predictive maintenance technologies

- Using vibration analysis to predict potential equipment failures

- Implementing thermal imaging for detecting overheating or electrical issues

- Using oil analysis to monitor equipment wear and tear

- Utilizing real-time sensor data to predict equipment performance issues

- Analyzing historical maintenance data to forecast future failures and maintenance needs

Continuous improvement in maintenance planning

- Analyzing maintenance data to identify trends and opportunities for improvement

- Implementing lean maintenance techniques to streamline maintenance processes

- Developing KPIs (Key Performance Indicators) for maintenance efficiency and effectiveness

- Conducting root cause analysis (RCA) to address recurring equipment issues

- Involving cross-functional teams in continuous improvement efforts for maintenance processes

Benefits Copied

With skills management software, organizations can plan and execute maintenance tasks effectively, preventing issues and minimizing downtime.

Download the free Excel Corrective and preventive maintenance planning skills matrix template Copied

We also have a free Excel template available that you can download if you are not ready to get started with AG5. To download it, please complete this form here.

Author Copied

Revisions Copied

Tired of managing skills in Excel?

Say goodbye to Excel matrices. Start using AG5’s plug and play skill matrix software.

Recognized by G2 for Excellence in Skills Management