Aerospace manufacturing skills certification and compliance

Build a living, role-based skills matrix that ties training, assessments, certificates, and authorizations to real work with expiry alerts, change-control triggers, and rapid evidence retrieval.

Aerospace compliance hinges on verifiable, role-based competence.

Every technician, inspector, and engineer must prove current qualifications, training, and practice against AS9100 and special-process standards, with traceable evidence ready for customer and regulatory audits at any time.

Aerospace manufacturing works under zero-defect expectations and tight oversight. Auditors don’t just ask whether you train people – they ask whether you can prove competence for each task, on each part, at a specific time and location.

That means defined role requirements, up-to-date certifications, disciplined assessments, and an auditable trail that links people, processes, and product.

Your baseline is AS9100D for quality management, with special processes (e.g., heat treat, NDT, welding, coatings) often governed by NADCAP.

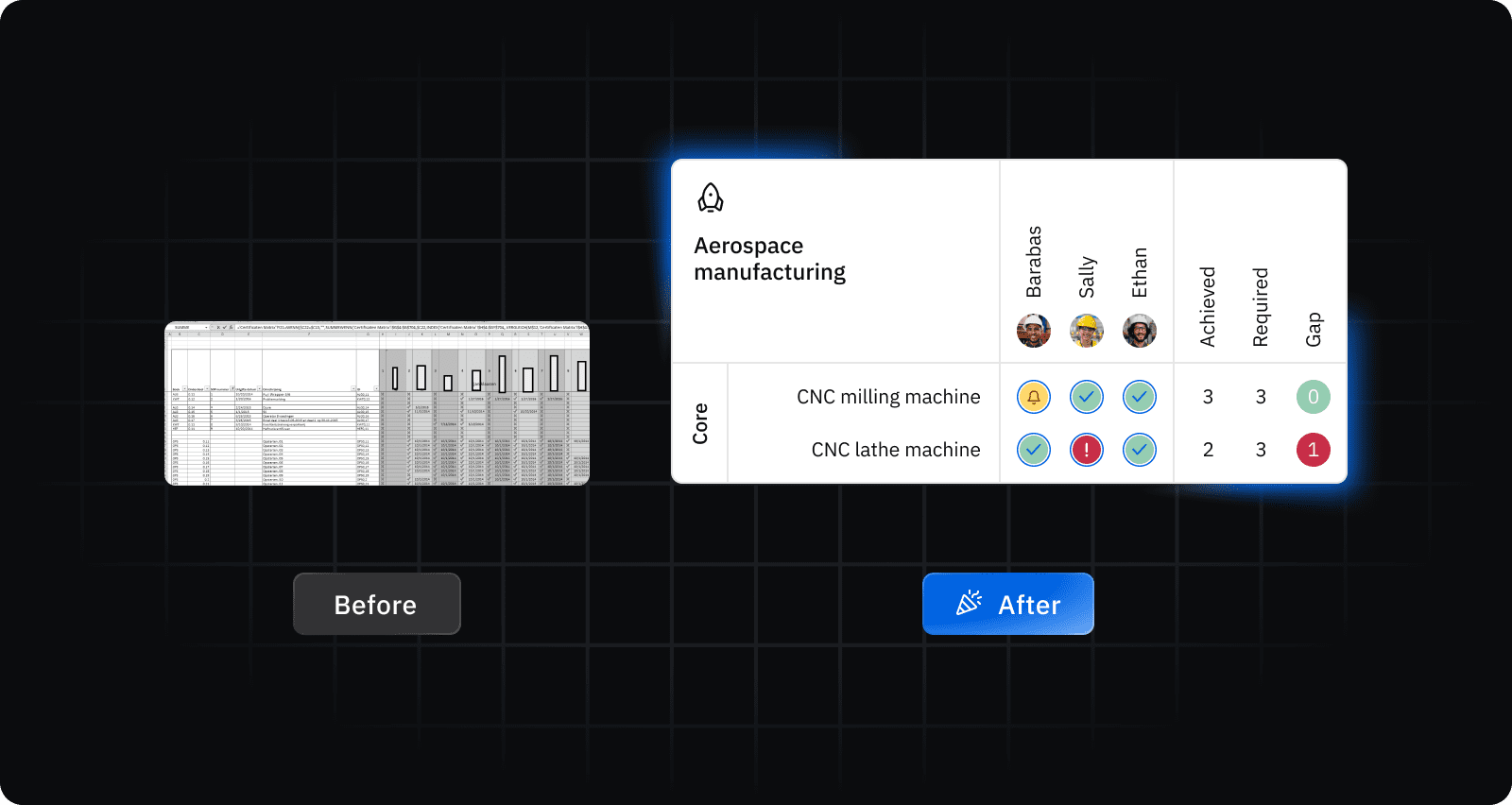

Add regional regulators (e.g., EASA/FAA) and customer-specific requirements, and you need a living skills matrix that aligns training, recertification, and shop-floor authorization, not a static spreadsheet.

This article shows how to structure certification programs, prevent skill decay, and align your skills matrix with audit-ready evidence, so you spend less time chasing documents and more time delivering compliant product.

What auditors expect to see

- Documented competence criteria by role and process

- Current certificates with issue/expiry dates and scope

- Assessment records and sign-offs tied to jobs or work centers

- OJT evidence, supervision logs, and recertification intervals

- Special-process qualifications and operator authorizations

- Traceable links from people to parts, travelers, and NCRs

| Standard or program | Competence focus |

|---|---|

| AS9100D | Defined competence, training effectiveness, records traceability |

| NADCAP (special processes) | Qualified personnel, approved procedures, periodic recertification |

| EASA/FAA Part 21/145 | Authorized staff, controlled training, maintenance and production approvals |

| AS9145 APQP/PPAP | Role clarity across planning, validation, and change control |

Why aerospace skill certification is critical to audit successCopied

Audits require objective proof that each person was competent at the moment work was performed. Role-based certifications connect training, assessments, and job authorizations to specific parts and dates, closing traceability gaps and reducing nonconformities during customer or regulatory reviews.

Aerospace auditors don’t accept verbal assurances – they verify evidence. When an NCR points to a special process, they trace who did the work, whether that person was qualified for that exact scope, and whether their certification was current.

Robust skills certification programs create that chain of custody: defined criteria per role, structured assessments, controlled OJT, periodic recertification, and documented authorizations tied to work orders or travelers.

The result is fewer audit findings, faster root-cause analysis, and easier customer approvals.

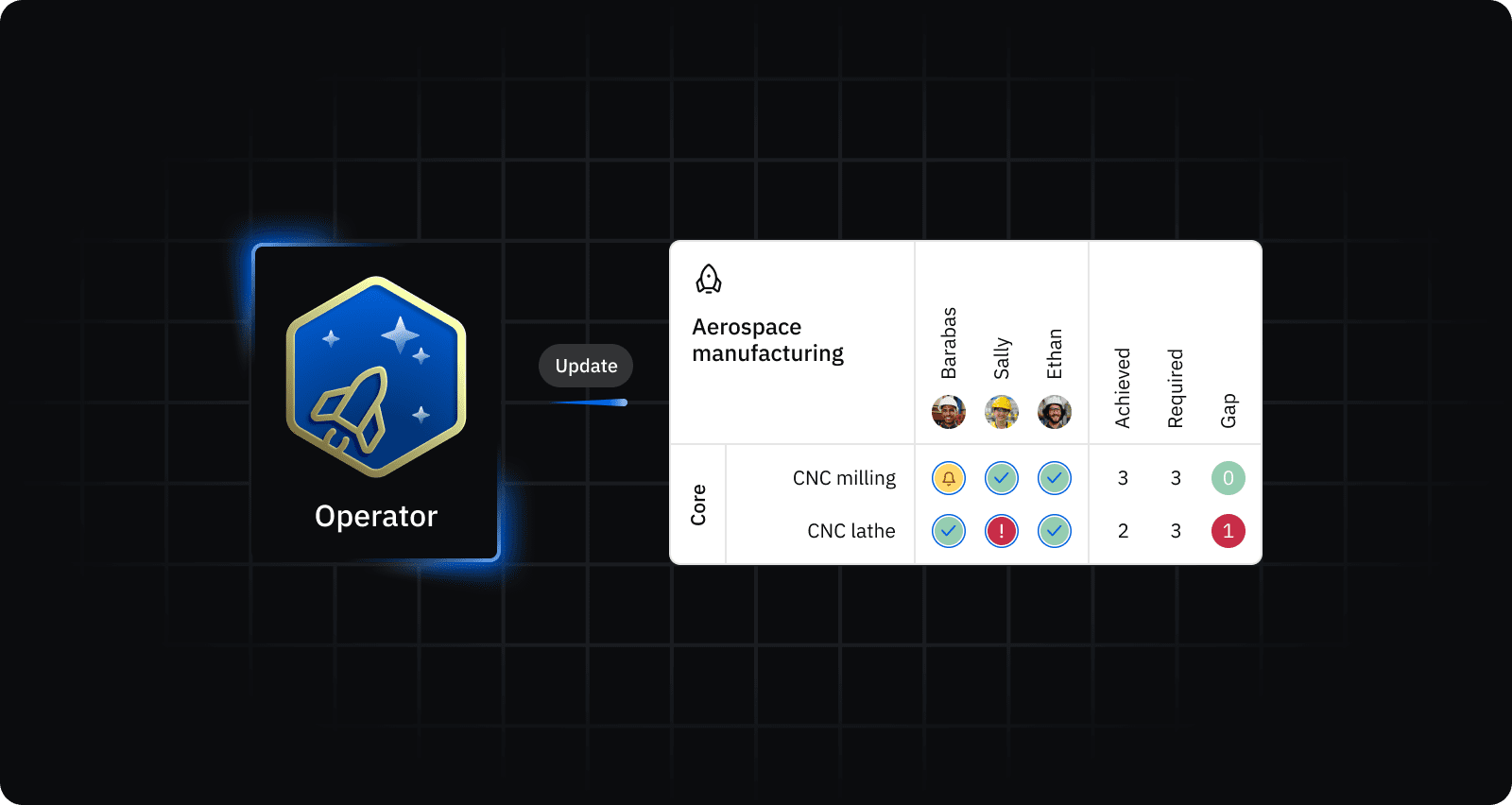

Practically, this looks like a living skills matrix backed by certificates with expiry alerts, supervisor sign-offs, and change-control records that show how people stayed competent as processes, equipment, and specifications evolved.

How certification reduces audit findings

- Links people, process, and product with time-stamped authorizations

- Prevents lapsed or out-of-scope qualifications on special processes

- Proves training effectiveness with documented assessments

- Speeds containment and corrective action with clear skill histories

Micro-checklist for audit day

- Current certificates and scope statements on file

- Assessment and OJT records mapped to job tasks

- Supervisor authorizations posted at work centers

- Recertification schedule with alerts and evidence of completion

What standards and frameworks matter in aerospace manufacturingCopied

The backbone is AS9100 for quality management [1], complemented by NADCAP for special processes, EASA/FAA approvals for regulated work, and AS9145 for APQP/PPAP.

All of them expect defined competence, effectiveness of training, and traceable records at audit time.

In practice, AS9100 sets the QMS baseline and requires you to determine needed competence, provide training, and retain evidence of effectiveness – auditors will check how your competence model ties to real jobs and records.

NADCAP applies when you run special processes (e.g., NDT, welding, heat treat): accreditation confirms procedures, equipment controls, and qualified personnel via rigorous PRI-led audits [2].

If you hold EASA Part 21 production approval or operate under FAA Part 145, you must maintain approved training programs and show recurrent competence for applicable staff [3].

Finally, AS9145 brings aerospace-grade APQP/PPAP discipline to new product introduction, forcing role clarity, documented plans, and evidence that people executing each phase are qualified [4].

Standards-to-competence

| Standard / Program | Scope | What You Must Prove at Audit |

|---|---|---|

| AS9100 (9100:2016) | QMS for aviation, space, defense | Defined competence, training effectiveness, and records linked to processes and roles |

| NADCAP (PRI) | Special processes accreditation | Qualified personnel, approved procedures, periodic recertification, successful PRI audits |

| EASA Part 21 (POA) | EU production approval | Controlled processes and competent staff under an approved system, documented in POA oversight |

| FAA 14 CFR Part 145 | US repair stations | FAA-approved initial and recurrent training program, with records available for inspection |

| AS9145 (APQP/PPAP) | New product introduction | Phase-gated plans, role/skill alignment, and evidence packages demonstrating readiness and control |

Quick actions to stay aligned

- Map each role to the relevant clauses (AS9100 7.2, NADCAP checklists, Part 21/145) and attach evidence sources

- Tag special-process operators for recertification intervals and supervisor authorizations

- Embed APQP/PPAP roles from AS9145 into your skills matrix for new programs [5]

How skills certification programs are structuredCopied

A robust program maps each role to required skills, defines clear qualification methods, stores auditable evidence, and enforces recertification cycles with alerts – all managed through a living skills matrix connected to training, work authorization, and change control

An aerospace-ready certification program starts with a role-based skills taxonomy and ends with audit-ready evidence.

For each role, define the skills, the acceptable qualification path (course, OJT, assessment, or external license), the authority to sign off, and the recertification interval.

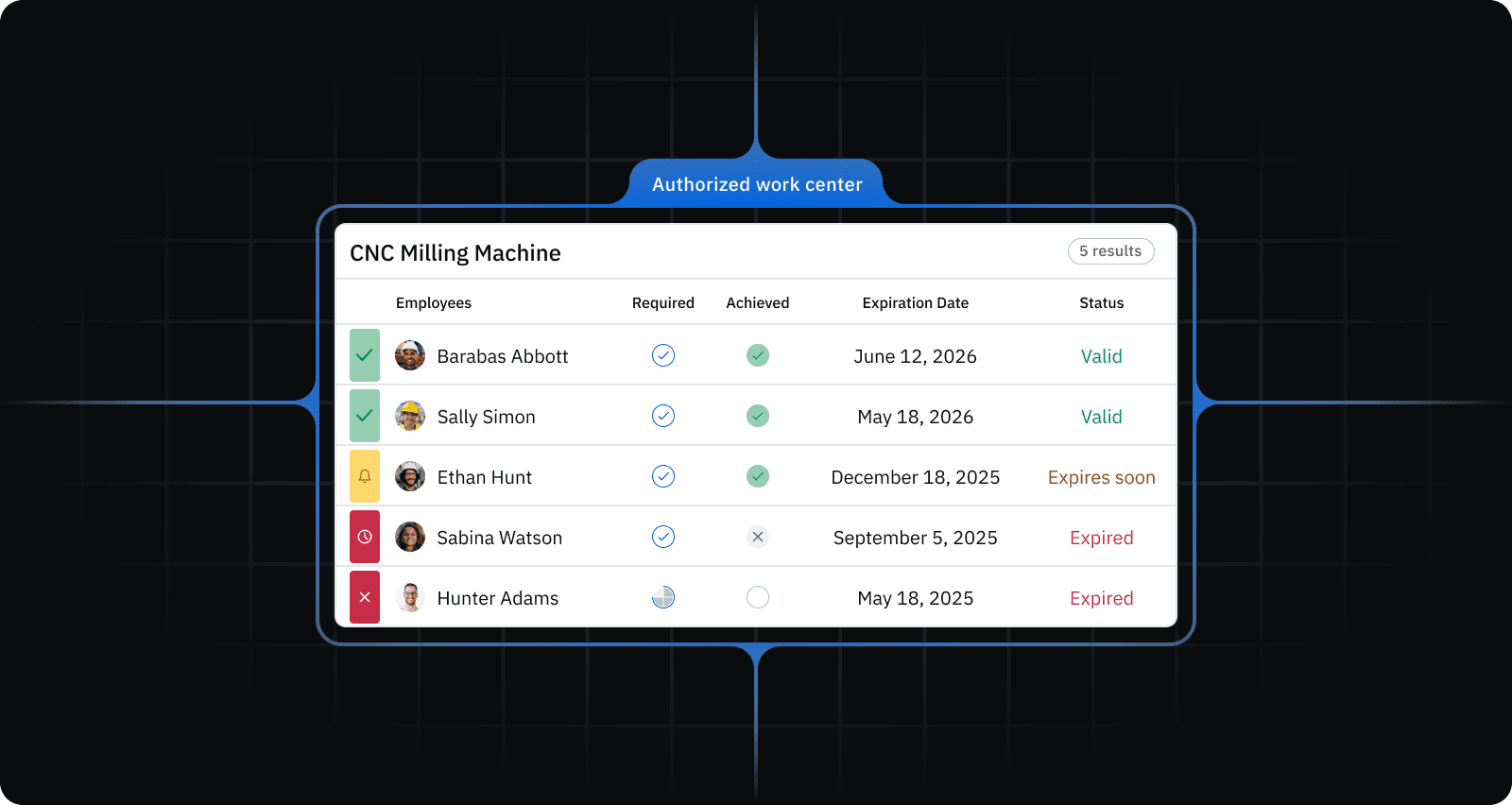

Tie every qualification to a verifiable record: certificate ID, scope, assessor, method, issue and expiry dates. Build supervisor authorizations and work-center restrictions on top, so only qualified people can touch special processes or critical tasks.

Finally, integrate training sources and change control, so when a spec or procedure changes, affected roles trigger retraining and re-authorization automatically.

Practically, this lives inside a skills matrix with certificate tracking, expiry alerts, and audit logs. This is not a static spreadsheet, but a system that updates with real work and real training.

Design principles

- Role before person

- Skill with a defined assessment method

- Evidence linked to the job or process

- Recertification cadence with automated alerts

- Supervisor authorization separate from training completion

Core building blocks

| Element | What It Defines | Example in Practice |

|---|---|---|

| Role taxonomy | Standard roles and variants | NDT Level II PT, Aerospace Welder GTAW |

| Competence criteria | What “qualified” means | Procedure X, spec Y, part family Z |

| Qualification method | How proof is earned | Course + exam, OJT hours, practical demo |

| Evidence package | What you must retain | Certificate PDF, assessor sign-off, scope statement |

| Validity window | When to recertify | 12–24 months, or after spec revision |

| Authorization | What work is permitted | Work-center A, process code B, traveler sign-off |

Evidence you’ll need on audit day

- Certificate or license with scope and dates

- Assessment records and OJT logs tied to skills

- Supervisor authorization mapped to work centers

- Change-control trace linking spec revisions to retraining

How to align training, skills matrix, and audit readinessCopied

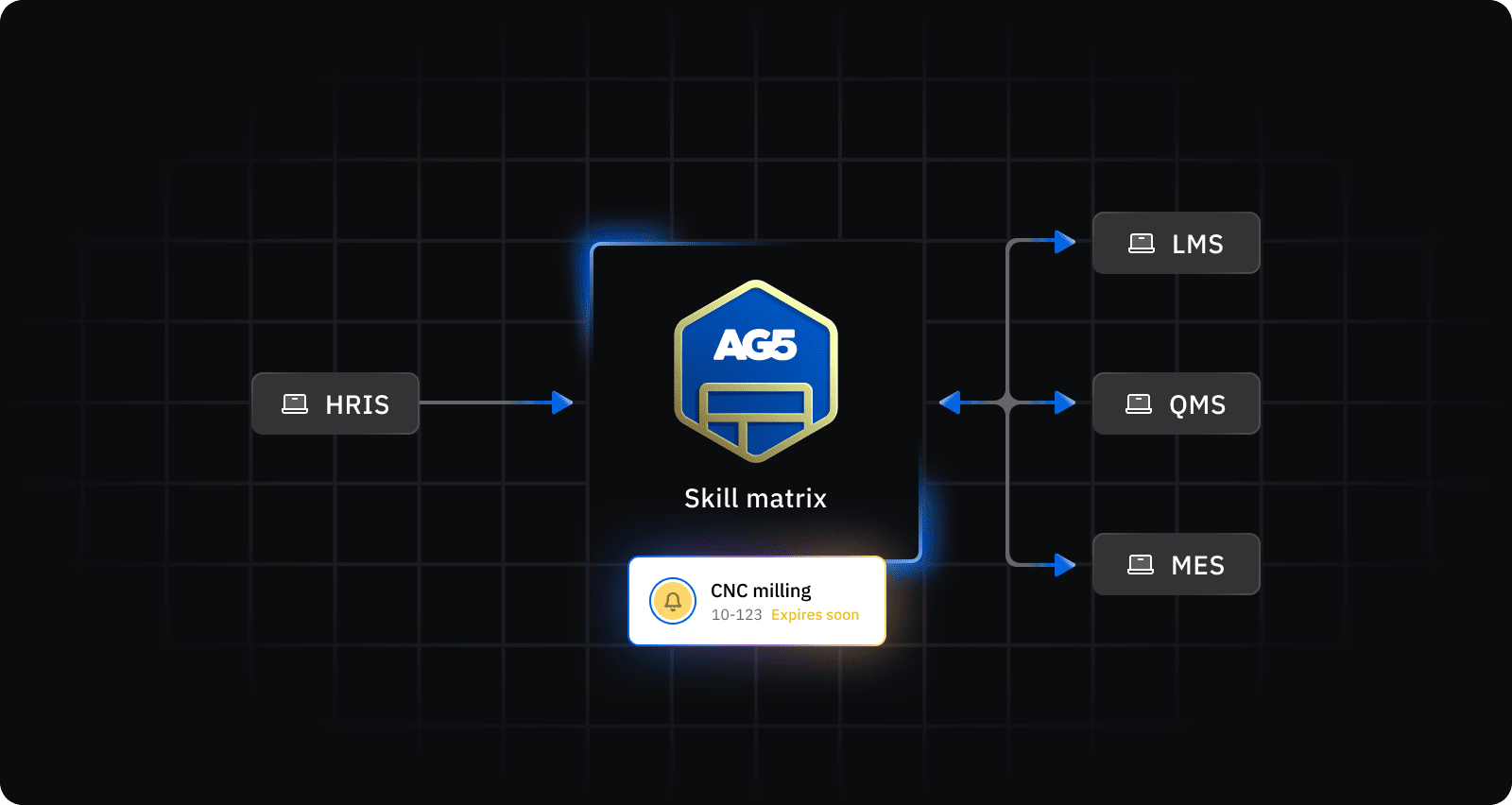

Connect your role-based matrix to your LMS and QMS so every required skill has a linked course, assessment, and authorization, with automated expiry alerts and change-control triggers. Validate the loop with internal audits and shop-floor spot checks

Start with people and roles in your skills matrix, not the tools. For each role, map required skills to specific courses and assessments, then bind completion to supervisor authorization at the work center.

Use your QMS for document control and change management so spec updates trigger retraining tasks automatically.

Feed HRIS master data to keep assignments current when people move, and pull MES or traveler data to prove the person who signed off was authorized that day. Finally, schedule mock audits to test evidence retrieval within minutes, not hours.

The goal is a closed loop: requirement → training → assessment → authorization → production evidence → periodic recertification.

Integration touchpoints

- HRIS for people data and role assignment

- Skills matrix for role requirements and authorization status

- LMS for courses, exams, and practical assessments

- QMS for controlled procedures and change notices

- MES/ERP for job history, sign-offs, and traceability

Audit evidence map

| Data Object | System of Record | Purpose in Audit |

|---|---|---|

| Role requirements | Skills matrix | Shows defined competence per role and process |

| Training records | LMS | Proves completion and assessment outcomes |

| Certificates | Skills vault / QMS DMS | Verifies scope, issue date, and expiry |

| Authorizations | Skills matrix / MES | Confirms who was permitted to do the work |

| Change notices | QMS | Links spec changes to retraining actions |

| Job history | MES / ERP | Ties person, part, date, and sign-off together |

Common gaps and mistakes in compliance skill programsCopied

The biggest failure points are traceability, scope mismatch, and lapsed recertification. Programs falter when role definitions are vague, assessments aren’t evidence-based, and authorizations aren’t linked to jobs.

Many aerospace shops “train and hope,” but auditors look for proof that a qualified person did the exact task under control.

Gaps appear when skills matrices are people-centric instead of role-centric, or when classroom completion replaces observed competence on the line. Another trap is letting certificates expire quietly or failing to recertify operators after a spec, procedure, or equipment change.

Finally, storing records in scattered spreadsheets slows evidence retrieval and undermines confidence during audits.

Shift your program to role-based requirements, codified assessment methods, automated expiry alerts, and work-center authorizations tied to travelers. Build change control into the loop so retraining triggers when documents update.

The goal is simple: the right person, proven competent, doing the right work, with evidence on demand.

Where programs stumble

- Vague role definitions and person-by-person matrices

- Training not mapped to procedures or part families

- Expired or out-of-scope certifications

- OJT without assessed proficiency or witness sign-off

- Supervisor authorization conflated with course completion

- Spec changes not linked to retraining tasks

- Spreadsheet silos and slow evidence retrieval

- Supplier/subcontractor competence not verified

| Symptom | Fastest Fix |

|---|---|

| People-centric matrix | Standardize role taxonomy and required skills |

| Course ≠ competence | Add practical assessments with documented criteria |

| Lapsed certs | Enable expiry alerts and recertification calendars |

| Slow audits | Centralize records with search and audit logs |

Roles & responsibilities in certification complianceCopied

Clear ownership prevents audit gaps. Quality defines competence and evidence; Engineering sets process requirements; L&D operationalizes training and assessments;

Supervisors authorize and monitor; Operators maintain currency; Internal auditors verify effectiveness and traceability across jobs, parts, and dates.

Aerospace compliance works when every function knows exactly what it owns and can prove it. Start by mapping roles to responsibilities and evidence. Quality determines competence criteria, record controls, and acceptance standards.

Engineering defines process qualifications and change control that trigger retraining. L&D (often with HR) turns role requirements into courses, assessments, and recertification cadences.

Production supervisors authorize who can run which process at which work center and monitor ongoing performance. Operators and inspectors keep qualifications current and capture OJT or observation sign-offs.

Internal audit pressure-tests the whole loop: is competence defined, current, and tied to real production evidence? Finally, supply chain validates subcontractor competence, especially on special processes, with documented reviews and approvals.

Who owns what

| Role / Function | Primary Ownership | Evidence You Should Have |

|---|---|---|

| Quality & regulatory | Competence criteria, records, acceptance | Controlled matrix, training effectiveness checks, audit logs |

| Engineering / process owners | Specs, process qualifications, changes | PQ docs, revision history, retraining triggers |

| L&D / HR | Courses, assessments, recertification | Curriculum map, exam results, OJT checklists |

| Production supervisors | Work-center authorization, oversight | Authorization lists, observation records, coaching notes |

| Operators / inspectors | Personal currency, scope adherence | Certificates, scope statements, badge / ID mapping |

| Internal audit | Program effectiveness, evidence retrieval | Audit plans, findings, CAPAs, verification records |

| Supply chain | Supplier competence & surveillance | Approved supplier list, special-process approvals |

Do this now

- Publish a one-page RACI for competence, training, authorization, and audits

- Tie change notices to named owners and automatic retraining tasks

- Require supervisors to re-confirm authorizations after every spec revision

Future trends and challenges in aerospace skills complianceCopied

Compliance is shifting toward digital traceability, special-process depth, and faster change cycles. Expect tighter flow-down from primes, additive and composite upskilling, data integrity controls for e-records, and risk-based recertification that proves competence continuously.

Aerospace programs now run on live data, digital twins, and multi-tier supply chains. That raises the bar for competence: operators must master new processes (AM, advanced NDT, composite repair), while auditors expect airtight traceability from person to part.

Primes are also pushing stricter flow-down on training and authorizations, so supplier readiness gets inspected, not assumed. Electronic records and e-signatures bring efficiency – but only if you can prove integrity, identity, and change control.

Finally, skills decay is under scrutiny; risk-based recertification models use usage frequency, defect data, and process changes to justify shorter (or longer) intervals.

Prepare by extending your skills matrix with process codes, linking it to MES travelers, and adopting dashboards that highlight risk, expiry, and capability coverage in real time.

Emerging trends to watch

- Digital thread linking people, procedures, equipment, and part travelers

- Additive manufacturing and advanced composites requiring new qualifications

- Prime contractor flow-down on supplier competence and audit readiness

- Data integrity for electronic training and authorization records

- Risk-based recertification tuned by usage and quality signals

- Cross-site standardization of roles, skills, and evidence models

- Human-automation teaming (cobots, NDI automation) with revised scopes

Trend-to-action

| Trend | What to Do | Matrix Update |

|---|---|---|

| Additive/composites growth | Define new role variants and special-process scopes | Add AM/composite skill IDs, method of assessment |

| Digital thread | Connect skills to MES traveler sign-offs | Column for operator ID ↔ traveler trace |

| Flow-down pressure | Include supplier competence checks in APQP | Supplier column with evidence link |

| Data integrity | Enforce unique IDs, e-sign, audit logs | Evidence field: signature hash, timestamp |

| Risk-based recert | Shorten intervals for low-use/high-risk tasks | Recert rules driven by usage metrics |

| Automation | Define human-robot task boundaries and training | Authorization tied to specific cells/equipment |

What to do now: Audit-ready checklistCopied

Use this condensed checklist to make your aerospace skills program audit-proof: standardize roles, map skills to assessment methods and evidence, automate expiry alerts, tie authorizations to work orders, and verify everything with internal audits and change-control triggers.

Turn the guidance into action with a short, repeatable cadence. Start by locking down a role taxonomy and linking each skill to a clear qualification path (course, OJT, practical demo) and evidence (certificate, assessor, dates, scope).

Build supervisor authorizations on top so only qualified personnel can run special processes or sign travelers. Connect your skills matrix to HRIS (people/roles), LMS (training/assessments), QMS (procedures/changes), and MES/ERP (job history/sign-offs).

Finally, schedule mock audits to prove you can retrieve records in minutes. AG5 helps here with role-based matrices, certificate tracking, expiry alerts, audit logs, and integrations so you spend less time chasing files and more time controlling risk.

30-60-90 day action plan

| Timeframe | Action | Owner | Evidence |

|---|---|---|---|

| 0–30 days | Lock role taxonomy; map skills to methods & evidence | Quality + Eng + L&D | Controlled matrix; criteria per skill |

| 31–60 days | Import certificates; enable expiry alerts; set recert rules | L&D / HR | Certificate vault; alert schedule |

| 61–90 days | Tie authorizations to work centers; link to travelers | Production + Quality | Authorization lists; MES sign-offs |

| Quarterly | Run mock audit; verify retrieval in ≤5 minutes | Internal audit | Audit log; CAPA follow-ups |

FAQs Copied

-

What’s the fastest way to become audit-ready if our records are scattered?

-

Do we need NADCAP if we already comply with AS9100?

-

How often should we recertify operators on special processes?

-

What evidence do auditors expect for competence?

-

How do we handle contractors or new hires during ramp-up?

-

What connects our skills matrix to the shop floor for traceability?

-

How do we prevent “course completion = competence” mistakes?

-

What should we verify with suppliers?

Sources Copied

- Change view: Table

-

APA

| # | Source title | Description | Publication | Retrieved | Source URL |

|---|---|---|---|---|---|

| 1 | 9100:2016 OVERVIEW | The IAQG is a legally incorporated international not for profit association (INPA) with membership from the Americas, Europe and the Asia Pacific Region | May 1, 2020 | October 21, 2025 | https://iaqg.org/wp-content/up.. |

| 2 | Nadcap®: The Global Standard for Aerospace Critical Process Accreditation | The Performance Review Institute (PRI) is a not-for-profit trade association started in 1990 | January 28, 2026 | October 15, 2025 | https://www.p-r-i.org/nadcap.. |

| 3 | User guide for Production organisations | EASA ensures confidence in safe air operations in Europe and world-wide by proposing and formulating rules, standards, and guidance; by certifying aircraft, parts, and equipment; and by approving and overseeing organizations in all aviation domains. | January 1, 1970 | October 16, 2025 | https://www.easa.europa.eu/en/.. |

| 4 | 9145 Advanced Product Quality Planning and Production Part Approval Process | The IAQG sets the standard for quality within the worldwide supply chain of the aerospace industry. As an international non-profit association under Belgian law with an office registered in Brussels (Belgium), the International Aerospace Quality Group (IAQG) was established in 1998. | - | October 21, 2025 | https://iaqg.org/standard/9145.. |

| 5 | What Is Competence? - Clause 7.2 of ISO9001/AS 9100 | ISA is a certification body headquartered in the U.S.A., providing business standards certification/registration to ISO 9001, AS9100 and AS9120 Quality Management Systems (QMS). | January 1, 1970 | October 16, 2025 | https://www.isaregistrar.com/w.. |

Author Copied

Revisions Copied

Written by: Rick van Echtelt

Copy edited by: Adam Kohut