Aerospace engineering skills management for audit-ready teams

Aerospace engineering skills must be tracked, validated, and proven at the right time. Learn how aerospace skills management software helps teams document competencies, manage training and certifications by process, identify gaps early, and stay audit-ready as operations scale.

The aerospace industry operates under some of the most demanding quality and safety standards in manufacturing. Every component, every process, and every person involved needs to meet strict requirements. Yet many aerospace companies still track employee skills, certifications, and training records across spreadsheets, shared drives, and email inboxes.

This scattered approach makes it hard to answer basic questions:

- Who’s qualified to work on a specific process?

- Which certifications are about to expire?

- Can we staff next week’s shift without compromising quality?

AG5 helps aerospace teams track aerospace engineering skills, training, and certifications against the needs of each production process, so you can identify gaps early, plan training, and stay audit-ready.

Why aerospace engineering skills management mattersCopied

Aerospace manufacturing isn’t just about having skilled people. It’s about proving competence at the right moment—during audits, when staffing critical processes, or when customer requirements change overnight.

Traditional tracking methods create several problems:

Visibility gaps: Without a central system, managers spend hours hunting for training records, checking spreadsheets across departments, and asking team leads who’s qualified for what.

Compliance risk: When certifications expire without warning or training records can’t be found quickly, you’re exposed during audits and customer reviews.

Operational delays: Production schedules get disrupted when you discover skill gaps too late, can’t find qualified replacements, or need emergency training sign-offs.

Scaling challenges: As programs grow or sites expand, manual tracking becomes impossible to maintain consistently.

A skills matrix solves these issues by creating a single, structured view of workforce competence mapped to your actual production needs. This structured approach to competency management ensures that every team member’s capabilities are documented and accessible.

What are aerospace engineering skills?Copied

Aerospace engineering skills are the technical and professional capabilities used to design, validate, and support aerospace products and processes. These skills often combine analytical problem-solving, safety awareness, and tool or process competence.

In practical terms, aerospace engineering skills include:

Technical foundations: CAD proficiency, drawing interpretation, understanding of aerodynamics and materials science, and the ability to apply math and physics to real manufacturing challenges.

Process competencies: Knowledge of specific production processes, work instruction adherence, inspection routines, and configuration management awareness.

Professional capabilities: Critical thinking for risk identification, attention to detail in quality-critical environments, cross-functional teamwork, and project management skills.

Regulatory awareness: Understanding industry standards, quality requirements, and the documentation discipline needed to prove competence during audits.

The specific skills your team needs depend on your products, processes, and customer requirements. However, the common thread across all aerospace operations is the need to track these skills systematically and demonstrate competence when it matters.

Creating a skills matrix for each unique aerospace production processCopied

Different production processes require different skill sets. A composites layup operation demands different competencies than CNC machining or final assembly. Generic training records don’t capture this nuance.

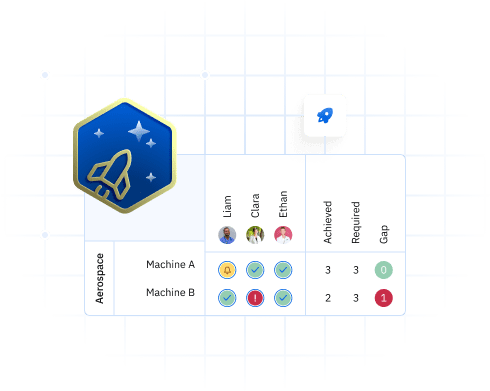

AG5 lets you track employee skills to the needs of your specific aerospace production processes—making it easier to identify skill gaps, find suitable replacements, and organize training programs.

How process-based skills matrices work

Start by defining what each production process actually requires. For a wing assembly process, you might need skills like:

- Torque application and fastener installation to specification

- Sealant application and cure time awareness

- Work instruction interpretation for this specific product line

- Quality inspection and documentation for aerospace standards

- Safety procedures for working with large structures

Then map your workforce against these requirements. You’ll quickly see who’s fully qualified, who has partial competency, who needs training, and where your coverage gaps exist.

This visibility changes how you plan. Instead of discovering a skill gap when someone calls in sick, you know your coverage situation weeks in advance. Instead of scrambling to find qualified people during audits, you have clear competence evidence ready to present.

Building matrices that match your operation

The most effective skills matrices mirror how work actually happens across your organization:

Production line or work center: Map skills to specific manufacturing areas where work happens, making daily staffing decisions straightforward.

Role or job function: Define what each position needs to know, creating clear training paths for new hires and role transitions.

Program or customer requirement: Track specialized competencies needed for specific contracts or products, especially when customer specifications vary.

Shift or site: Maintain visibility across multiple locations or time periods, ensuring consistent competence coverage throughout your operation.

A competency management system makes this mapping process manageable. Instead of maintaining dozens of spreadsheets, you build matrices once and update them as processes or requirements change.

Identifying who needs training before quality or delivery is impactedCopied

Reactive training management is expensive. Certifications expire after parts have already been worked on. Skill gaps appear when production is already planned. Staffing constraints are identified only as a shift is about to start.

Proactive training management prevents these situations by making skill status visible and expiry dates actionable.

Common training challenges in aerospace manufacturing

Aerospace teams often need to manage several competing demands:

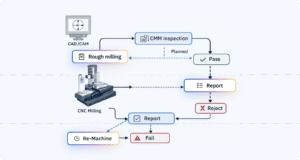

Critical process authorizations and sign-offs: Certain operations require specific qualifications. You can’t substitute someone else without proper authorization, which means gaps directly impact production capability.

Cross-site staffing flexibility: Multi-site operations need people who can work across locations, but different sites might use different processes or have different customer requirements.

Training requirements that change as processes and programs evolve: New product introductions, process improvements, and changing customer specifications all trigger training needs that must be tracked and completed.

Recertification cycles that vary by skill type: Some competencies need annual renewal, others expire every two years, and some require revalidation after process changes.

AG5 helps you spot gaps and prioritize training based on operational risk. The system uses role-based matrices, expiry alerts, and integrations that reduce manual chasing.

Setting up effective training visibility

Good training management starts with clear ownership and automated reminders:

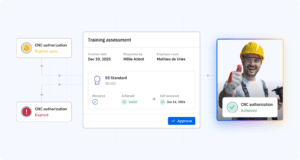

Expiry tracking: Set expiration dates for certifications, process authorizations, and time-limited training. Get automatic alerts before credentials expire, not after.

Gap analysis: Compare required skills against current workforce competence to identify where training is needed most urgently.

Training prioritization: Focus on gaps that affect critical processes, customer deliverables, or audit readiness rather than treating all training equally. Effective training management helps you allocate resources where they’ll have the most impact.

Progress tracking: Monitor who’s enrolled in training, who’s completed required courses, and where bottlenecks exist in your training pipeline.

Understanding how it works helps you set up a system that actually prevents problems instead of just documenting them after they happen.

Staying audit-ready with clear competence evidenceCopied

Audits are stressful when competence records are scattered. Customer auditors ask to see training records for specific people working on their products. Internal quality reviews need evidence that only qualified personnel performed critical operations. Regulatory inspections require proof of ongoing competency management.

If your records live across multiple systems, finding this evidence takes hours or days. If you can’t find it at all, you’ve got a serious compliance problem.

Why aerospace competence standards are strict

AS9100 is widely used in aerospace quality management and adds requirements on top of ISO 9001. Competence is explicitly addressed as a requirement area. The standard requires organizations to determine necessary competence for personnel affecting product quality, ensure personnel are competent based on appropriate education, training, or experience, and maintain documented information as evidence of competence.

This isn’t about bureaucracy. It’s about ensuring that aerospace products—which must perform reliably in demanding conditions—are built by people who know what they’re doing and can prove it.

AG5 supports this by keeping competence evidence current and reportable. Whether you’re preparing for customer audits or aligning to aerospace quality expectations, the fastest wins come from making competence evidence easy to retrieve.

Building audit-ready competence systems

Effective competence management for audits includes:

Centralized records: Keep all training certificates, qualification records, and competency assessments in one searchable location.

Role-based documentation: Link competence evidence to the specific roles and processes where it’s needed, making it easy to show that qualified people performed critical work.

Version control: Track when training was completed, which version of work instructions or processes applied, and when retraining occurred after changes.

Quick reporting: Generate competence reports by role, process, person, or time period in minutes rather than hours or days.

For more details on aerospace-specific compliance approaches, see our guide on aerospace manufacturing skills certification and compliance.

Aerospace engineering skills list (examples you can track)Copied

Knowing what skills to track is the foundation of good competence management. Here are practical examples of aerospace engineering skills that teams commonly build into their skills matrices.

Technical aerospace engineering skills

CAD proficiency and drawing interpretation: Reading and understanding engineering drawings, working with 3D models, and interpreting geometric dimensioning and tolerancing (GD&T) requirements. This skill ensures tooling and standard work alignment across the production floor.

Analytical and critical thinking: Identifying risks in designs or processes, making informed tradeoffs between competing requirements, and solving complex problems that arise during manufacturing. Engineers need to think through cause and effect in systems where small changes can have significant impacts.

Math and science fundamentals applied to aerospace contexts: Understanding aerodynamics principles, structural mechanics, material properties, and thermal dynamics as they apply to real aerospace components and assemblies.

Attention to detail and safety awareness: Operating in quality-critical and safety-critical environments where small errors can have serious consequences. This includes following procedures exactly, catching mistakes before they propagate, and maintaining safety discipline.

Project and time management: Coordinating work across multiple teams, meeting program deadlines, and managing priorities when multiple demands compete for limited resources.

Practical manufacturing engineering competencies

Process-specific authorizations and work instruction competence: Being qualified to perform specific operations like welding, coating, heat treating, or non-destructive testing according to approved procedures.

Inspection and verification routines: Conducting quality checks at appropriate process stages, using measurement equipment correctly, and documenting results with the required level of detail.

Configuration and change awareness: Understanding which revision of a design or process applies, recognizing when engineering changes affect work, and ensuring proper implementation of modifications.

Training completion and recertification requirements: Maintaining current status on required training tied to specific programs, processes, or customer requirements.

If you’re starting from scratch, an aviation skills matrix template can help you structure your first competency model before moving to a full system.

How AG5 helps manage aerospace engineering skillsCopied

AG5 turns engineering skills into a structured competency model with several practical components:

Role-based matrices: Define what each role needs to know and track each person’s progress against those requirements. This creates clear expectations for employees and visibility for managers.

Evidence tracking: Upload and store training certificates, qualification records, and competency assessments. Link evidence to specific skills so auditors can find what they need quickly.

Gap visibility: See at a glance where skill shortages exist, which processes are at risk, and who needs training most urgently. This turns reactive scrambling into proactive planning.

Expiry alerts: Get automatic notifications before certifications expire or recertification is due. Stop relying on memory or manual calendar checks.

Audit-ready reporting: Generate competence reports filtered by role, process, skill, person, or time period. Turn hours of manual data gathering into minutes of report generation.

The goal isn’t to add bureaucracy. It’s to make competence management faster, more reliable, and less stressful for everyone involved.

Why aerospace teams use skills matricesCopied

Skills matrices make readiness visible by role and process. They answer questions like: Who is qualified for what? Where do gaps exist? What training is needed? These questions come up constantly across multiple programs, sites, and shifts.

Practical scenarios where skills matrices help

Shift planning: When scheduling production, you need to know if each shift has adequate coverage of critical skills. A skills matrix shows this instantly instead of requiring phone calls and email chains.

Program ramps: New product introductions require specific competencies. A matrix helps you identify who needs training before the first production unit is scheduled, not after.

Cross-training decisions: When planning workforce flexibility, you need to know who has partial competency in adjacent areas and could be developed quickly. Skills matrices make these decisions data-driven instead of based on assumptions.

Hiring and recruiting: Understanding your team’s current competency profile helps you target hiring toward your actual skill gaps rather than generic “experienced aerospace engineer” requirements.

Audit preparation: When customers or registrars request competence evidence, a skills matrix provides the structure to present it clearly and completely.

Best practices for aerospace skills trackingCopied

Implementing effective skills management requires more than just software. Here are practical approaches that work:

Start with critical processes

Don’t try to map every possible skill on day one. Start with your most critical production processes—the ones that affect quality, delivery, or compliance most directly. Build matrices for these areas first, prove the value, then expand.

Define skills clearly

Vague skill descriptions create confusion. “Welding knowledge” could mean anything. “TIG welding per AWS D17.1 for aluminum aerospace structures” is specific enough to train, test, and track.

Involve the people who do the work

Engineers and technicians know what competencies their work actually requires. Get their input when building skills matrices. They’ll catch requirements that desk-based analysis misses, and they’ll have more ownership of the system.

Keep matrices current

Skills requirements change as processes improve, products evolve, and customer specifications are updated. Schedule regular reviews of your skills matrices—at least annually, more often for rapidly changing areas.

Connect training to gaps

Don’t just identify gaps; create clear paths to close them. When someone lacks a required skill, they should know what training is available, how to enroll, and when they’ll be qualified.

Make data accessible

Skills information helps multiple teams: production planning needs it for scheduling, HR needs it for development planning, quality needs it for audit preparation. Make sure relevant stakeholders can access the information they need without creating security risks.

Moving beyond spreadsheetsCopied

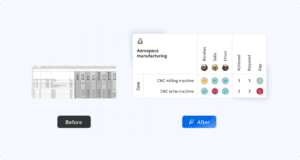

Many aerospace teams start skills tracking in Excel. Spreadsheets are familiar, flexible, and don’t require budget approval. But as tracking needs grow, spreadsheet limitations become painful:

Version control chaos: Multiple copies of the “master” spreadsheet float around with conflicting information. Nobody’s sure which version is current.

Update bottlenecks: One person owns the spreadsheet and becomes a bottleneck for updates. Training gets completed but doesn’t get recorded for weeks.

No automation: Certifications expire without warning because spreadsheets can’t send alerts. Gap analysis requires manual sorting and filtering every time you need it. Automated skills tracking software eliminates these manual processes.

Limited reporting: Creating audit-ready reports from spreadsheets means exporting, reformatting, and manual cleanup every single time.

Scaling problems: What works for one team of 20 people breaks down completely for three shifts across two sites with 200 people.

Moving to dedicated skills management software solves these problems. You get automated alerts, real-time updates, standardized reporting, and the ability to scale without losing control.

The transition doesn’t have to be complicated. Many teams start by migrating one critical process from spreadsheets to a skills management system, validating that it works, then expanding from there.

Getting started with aerospace skills managementCopied

If you’re ready to improve how your organization tracks aerospace engineering skills, here’s a practical starting path:

Assess your current state

Document how you track skills today. Where do records live? Who maintains them? What works well and what causes problems? This baseline helps you measure improvement and identify quick wins.

Define your requirements

What do you need your skills management system to do? Common requirements include tracking certifications, managing expirations, generating audit reports, and analyzing skill gaps. Prioritize these by importance and urgency.

Select critical areas

Choose 2-3 production processes or roles where better skills visibility would have immediate impact. Focus your initial implementation here rather than trying to do everything at once.

Build initial matrices

Create skills matrices for your selected areas. Define required competencies, map current workforce against them, and identify gaps. This exercise alone often reveals surprises about your actual competence coverage.

Implement and refine

Put your system into production use. Track what works, what needs adjustment, and what value you’re getting. Use early wins to build support for broader rollout.

Expand systematically

Once you’ve proven the approach in critical areas, expand to additional processes, roles, and sites. Each expansion gets easier as your team becomes familiar with the system and approach.

See how AG5 supports aerospace competence and training oversightCopied

AG5 helps aerospace manufacturers track engineering skills, certifications, and training against production process needs. The system identifies gaps early, keeps teams audit-ready, and makes competence evidence easy to find when customers, auditors, or internal reviews need it.

Book a demo to see how AG5 maps aerospace engineering skills to production processes, identifies gaps, and keeps your organization audit-ready. You’ll see the actual system, discuss your specific requirements, and understand how skills management software could work in your operation.

FAQs Copied

-

What are aerospace engineering skills?

-

How does AG5 help manage aerospace engineering skills?

-

Why do aerospace teams use skills matrices?

-

What's the difference between a skills matrix and a training record?

-

How often should aerospace skills matrices be updated?

-

Can skills management software integrate with existing training systems?

-

What's required to maintain AS9100 compliance for competence?

-

How long does it take to implement aerospace skills management software?

Author Copied

Revisions Copied

Written by: Rick van Echtelt

Copy edited by: Adam Kohut