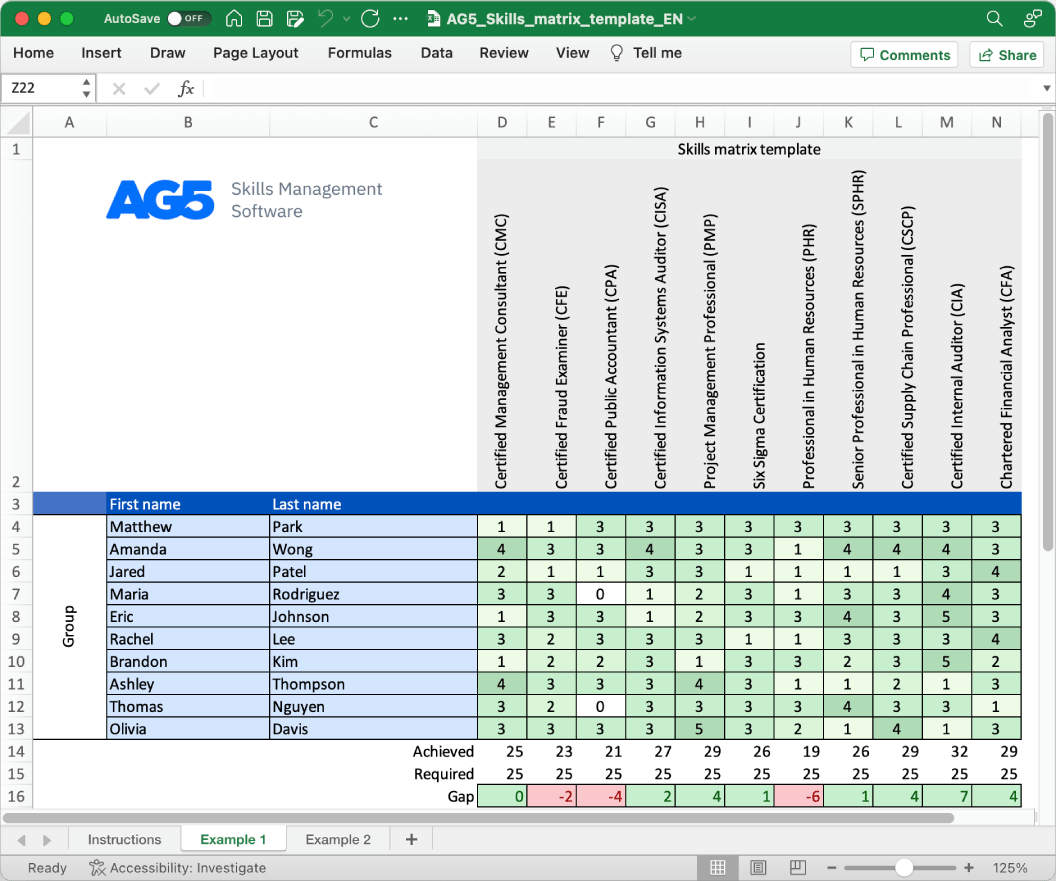

Process engineering skills matrix template

A skills matrix template is a tool teams can use to effectively manage and assess their processing engineering skills and knowledge.

Download your free template here

Overview Copied

With our free process engineering skills matrix template, you will receive a clear overview of the skills that are present in your organization, as well as those that are missing. Using this information, you can develop and implement a plan to ensure that your employees’ skills in process engineering are up to date, comprehensive, compliant, and ready for the future.

- Certified Process Engineer (CPE)

- Six Sigma Green Belt Certification

- Certified Process Safety Professional (CCPSC)

- Lean Six Sigma Black Belt Certification

- Certified Process Improvement Practitioner

- ISO 9001 Lead Auditor Certification

- Certified Process Design Engineer

- Certified Process Control Professional (CPCP)

- Certified Process Optimization Specialist

- Certified Reliability Engineer (CRE)

- Certified Process Simulation Engineer

- Certified Process Integration Engineer

- Certified Process Validation Professional

- Certified Process Mapping Expert

- Certified Process Analytics Specialist

- Certified Process Modeling and Simulation Specialist

- Certified Statistical Process Control (SPC) Practitioner

- Certified Process Automation Engineer

- Certified Process Safety Management (PSM) Auditor

- Certified Process Monitoring and Troubleshooting Professional

Benefits Copied

Skills management software is important in process engineering to effectively track and manage the diverse skills and competencies of process engineers. It enables organizations to identify and allocate the right resources for specific projects, monitor skill gaps, plan training programs, and ensure that the necessary expertise is available to optimize processes, improve efficiency, and drive continuous improvement initiatives.

Author Copied

Revisions Copied

Use AG5 to identify skill gaps

Say goodbye to Excel matrices. Start using AG5’s plug and play skill matrix software.

ISO27001 certified Free trial available