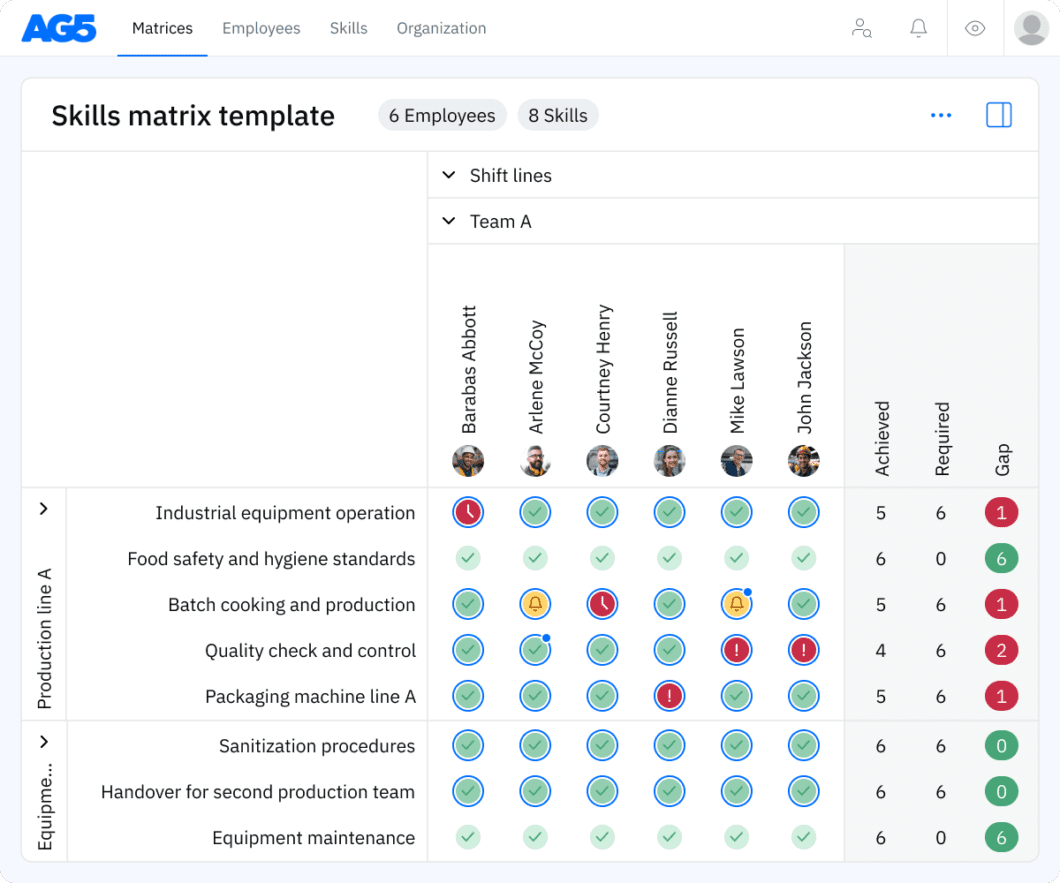

Plating and surface finishing industry skills matrix template

A skills matrix template is a tool that can be used in the plating and surfacing finishing indusry to effectively manage and assess the skills and knowledge of individual employees or teams.

Download your free template here

Overview Copied

With our free plating and surface finishing industry skills matrix template, you will receive a clear overview of the skills that are present in your organization, as well as those that are missing. Using this information, you can develop and implement a plan to ensure that your employees’ skills are up to date, comprehensive, compliant, and ready for the future.

Surface preparation and cleaning

- Understanding and applying surface cleaning techniques (e.g., degreasing, pickling, and abrasive blasting)

- Selecting the appropriate cleaning methods based on the material type and finishing requirements

- Ensuring thorough removal of contaminants, oils, and oxides prior to plating or finishing

- Handling and disposing of cleaning chemicals safely in accordance with environmental regulations

- Inspecting surfaces for cleanliness and preparation adequacy before the finishing process

Electroplating techniques and processes

- Operating electroplating equipment for various metals (e.g., chrome, nickel, zinc)

- Controlling plating parameters such as current density, temperature, and time for optimal coating

- Monitoring bath chemistry and making necessary adjustments to ensure consistent quality

- Understanding the differences in plating for different materials (e.g., steel, aluminum, brass)

- Preventing plating defects such as pits, blisters, or uneven coatings through proper process control

Coating application and finishing

- Applying various types of protective coatings, such as anodizing, powder coating, or painting

- Ensuring uniform application of coatings and achieving desired thickness

- Using curing and drying processes to set coatings for durability and corrosion resistance

- Inspecting finished parts for coating quality, adhesion, and surface finish consistency

- Implementing corrective measures for coating defects, such as orange peel or uneven layers

Quality control and testing

- Performing adhesion and hardness testing on finished surfaces to ensure durability

- Conducting thickness measurements using tools like micrometers, calipers, and X-ray thickness testers

- Inspecting finished parts for surface finish, defects, and uniformity using visual and automated techniques

- Applying non-destructive testing (NDT) methods to evaluate surface integrity and adhesion

- Recording and reporting test results for quality assurance and continuous improvement processes

Benefits Copied

Skills management software is important in the polymer industry as it helps ensure that employees are trained and equipped with the necessary skills to manufacture, test, and package polymers efficiently and safely, and that they comply with industry regulations and customer requirements.

Download the free Excel Plating and surface finishing industry skills matrix template Copied

We also have a free Excel template available that you can download if you are not ready to get started with AG5. To download it, please complete this form here.

Author Copied

Revisions Copied

Tired of managing skills in Excel?

Say goodbye to Excel matrices. Start using AG5’s plug and play skill matrix software.

Recognized by G2 for Excellence in Skills Management