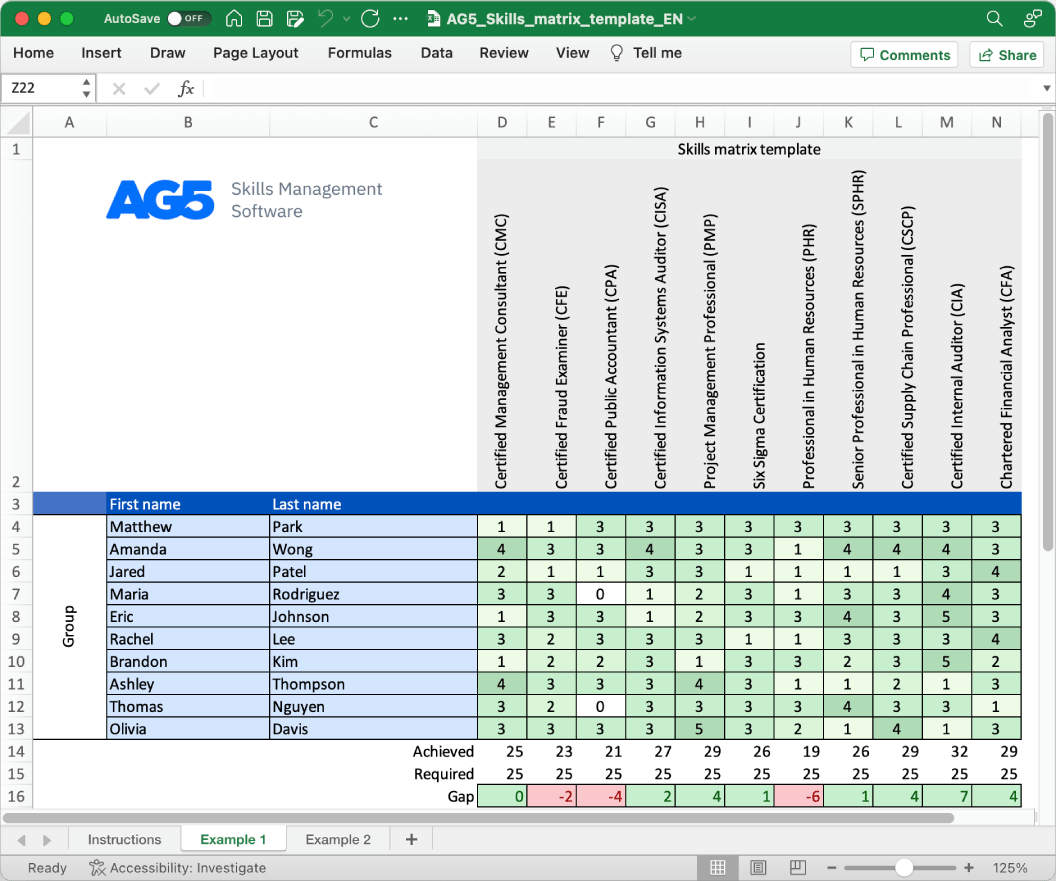

Composite materials manufacturing industry skills matrix template

A skills matrix template is a tool that can be used in the composite materials industry to effectively manage and assess the skills and knowledge of individual employees or teams.

Download your free template here

Overview Copied

With our free composite materials manufacuturing skills matrix template, you will receive a clear overview of the skills that are present in your organization, as well as those that are missing. Using this information, you can develop and implement a plan to ensure that your employees’ skills are up to date, comprehensive, compliant, and ready for the future.

- Certified Composite Technician (CCT)

- Certified Composite Manufacturing Engineer (CCME)

- Composites Technician Program Certification

- Lean Manufacturing Certification

- Six Sigma Green Belt Certification

- ISO 9001 Certification

- ISO 14001 Certification

- Root Cause Analysis Certification

- Occupational Health and Safety Assessment Series (OHSAS) Certification

- National Institute for Occupational Safety and Health (NIOSH) Certification

- ANSI Z10 Certification

- Occupational Safety and Health Administration (OSHA) Certification

- Certified Quality Engineer (CQE)

- Certified Maintenance and Reliability Professional (CMRP)

- Total Quality Management (TQM) Certification

- Certified Manager of Quality/Organizational Excellence (CMQ/OE)

- American Society for Composites (ASC) Certification

- American Society for Testing and Materials (ASTM) Certification

- Society of Manufacturing Engineers (SME) Certification

- National Aerospace and Defense Contractors Accreditation Program (NADCAP) Certification

Benefits Copied

Skills management software is important in the composite materials manufacturing industry as it helps ensure that employees are trained and equipped with the necessary skills to manufacture, test, and package composite materials efficiently and safely, and that they comply with industry regulations and customer requirements.

Author Copied

Revisions Copied

Tired of managing skills in Excel?

Say goodbye to Excel matrices. Start using AG5’s plug and play skill matrix software.

Recognized by G2 for Excellence in Skills Management