The top 10 AI skills transforming manufacturing in 2025

In 2025, AI is transforming manufacturing through robotics and automation — but only if workers have the right skills. This article explores the 10 most valuable AI skills on the factory floor, from predictive maintenance to digital twins, and shows how to track and develop them with real-time skills management.

As of this 2025, 90% of manufacturers have adopted “some form” of AI technologies into their business operations [1].

Smart robots are collaborating alongside human workers, predictive algorithms are preventing costly equipment failures, and AI-powered systems are optimizing everything from inventory levels to energy consumption. From here, demand for AI will continue to grow – as will the industry. Valued at $5.94 billion in 2024, the global AI market in manufacturing is anticipated to reach $60.7 billion by 2034 [2].

This means manufacturers will need to ensure their workforces have the right skills to use AI-powered technologies effectively.

One key challenge is knowing who has these skills and how to develop them in a structured way. Traditional methods – like spreadsheets, manual assessments, and outdated systems – can’t keep up with how fast AI in manufacturing is evolving.

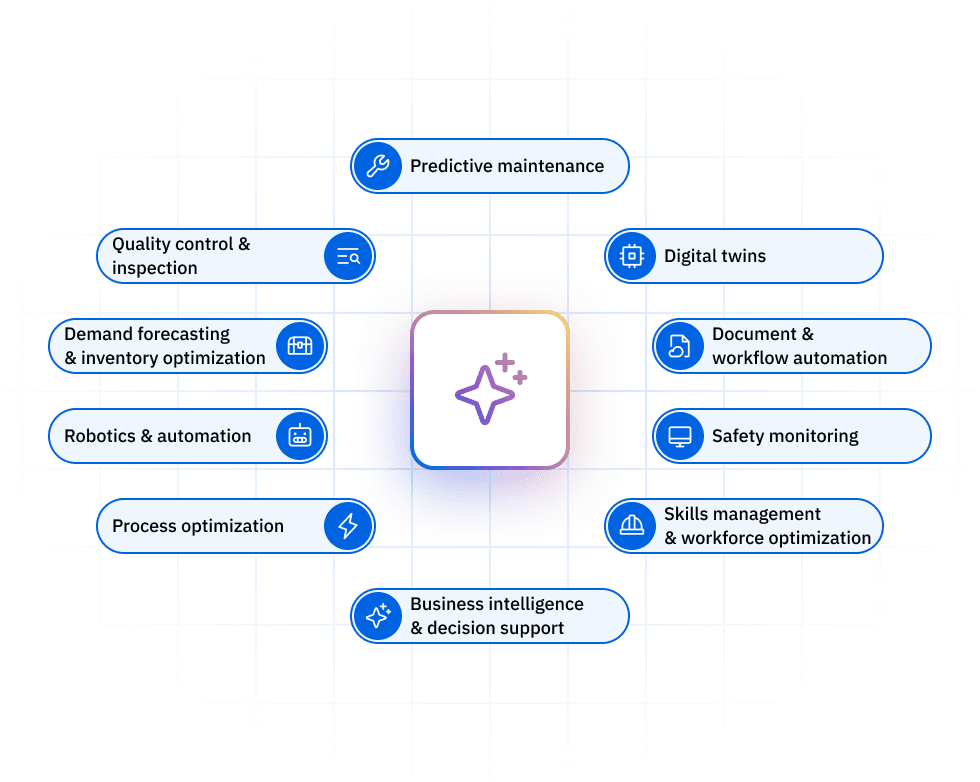

In this article, we’ll examine the top 10 AI skills that hold the most value in 2025 future, with a focus on those applied to robotics and automation. We’ll also shine a spotlight on how AG5’s skills management platform provides manufacturers with real-time visibility into their workforce’s capabilities, and sets clear pathways for developing the AI skills that will define competitive advantage for years to come.

How robotics and automation are reshaping manufacturingCopied

As technology surrounding robotics and automation evolves, machines are increasingly capable of handling tasks once performed by people, but faster, with more precision, and around the clock.

Smart robots and automated systems are already improving efficiency, reducing errors, and making factories safer. For example, collaborative robots – known as “cobots” – can work with humans on – or even fully take over – repetitive or dangerous tasks.

However, upgrading the tools isn’t enough. Workers also need to upgrade their skills. Automation and robotics are creating demand for new roles that require digital and technical knowledge, such as robot maintenance and data analysis [3]. Companies that want to stay competitive need to invest in training their workforce: both in using machines and in understanding how they work.

Why AI skills are becoming mission-critical on the factory floorCopied

As automation scales across manufacturing operations, AI fluency is shifting to a necessity. This massive adoption creates urgent demand for workers who can operate alongside AI systems and actively leverage them to drive innovation and efficiency.

The skills gap here is particularly acute. While traditional manufacturing skills are focused on mechanical operations, today’s workers need to understand how AI algorithms make decisions, interpret data-driven insights, and troubleshoot intelligent systems.

The 10 essential AI skills driving innovation in manufacturingCopied

1. Predictive maintenance

Predictive maintenance represents one of the highest-value applications of AI in manufacturing. It involves using AI to monitor equipment data from sensors, vibration analyzers, and maintenance logs to identify early signs of failure. Workers skilled in predictive maintenance help avoid costly downtime and can significantly extend equipment life.

Real-world examples include:

- Predicting motor burnout by analyzing current fluctuations

- Detecting unusual vibration patterns indicating bearing wear

- Identifying temperature anomalies suggesting impending system failures

2. Quality control & inspection

AI-powered quality control transforms inspection processes through computer vision and machine learning, alerting employees to defect detection in real-time – and with unprecedented accuracy and speed. Such AI systems can improve defect detection, as well as work faster and more accurately than manual inspection.

For example:

- Welders can operate AI systems that inspect welds for structural integrity, measure dimensions with microscopic precision, and identify surface flaws

- Automotive manufacturers can use AI vision systems to inspect paint quality

- Electronics manufacturers verify component placement on circuit boards with extremely high accuracy rates

3. Demand forecasting & inventory optimization

AI-driven demand forecasting analyzes historical sales data, market trends, and external factors to predict future product demand with remarkable accuracy. This prevents costly overproduction and stockouts by allowing manufacturers to align production with real demand.

Examples in manufacturing include:

- Electronics manufacturers forecasting demand for components like chips or batteries

- Automotive plants predicting parts and vehicle demand across regions

- Packaging producers aligning output with seasonal spikes in food and beverage sales

4. Robotics & automation

Modern AI makes robots smarter and more adaptable. Workers can manage collaborative robots that work safely alongside humans, program robots for complex assembly tasks, and maintain AI-powered automation equipment. These AI-driven capabilities increase production efficiency while allowing for more flexible manufacturing setups.

Real-world examples include:

- BMW’s intelligent robots that adapt assembly processes for different car models without reprogramming [4]

- Amazon’s warehouse robots that coordinate autonomously to optimize picking routes [5]

5. Process optimization

AI can analyze real-time production variables – think speed, temperature, pressure, and energy consumption – and automatically adjust them for optimal outcomes. Workers are able to monitor

AI systems that make thousands of micro-adjustments per hour with higher output quality, reduced material waste, and lower energy usage, all in real time.

Real-world examples of AI-driven process optimization in manufacturing include:

- Steel manufacturers optimizing furnace operations, with some organization reporting a 5% reduction in energy consumption while maintaining quality [6]

- Pharmaceutical companies maintaining precise environmental conditions during drug production

6. Digital twins

Digital twins are virtual models of physical machines or systems. AI uses these models to simulate performance and test changes without disrupting actual operations – reducing trial-and-error in physical setups, speeding up design cycles, and improving operational decision-making

Examples of digital twins in the manufacturing industry include:

- Aerospace manufacturers simulating aircraft engine performance under extreme conditions

- Automotive companies testing production line configurations virtually before physical implementation

7. Document & workflow automation

AI automates back-office processes like order processing, compliance documentation, and report generation using natural language processing (NLP) and robotic process automation (RPA). Automating routine workflows saves time, cuts down on manual errors, and allows staff to focus on higher-value tasks.

For example:

- Pharmaceutical companies can automatically generate compliance reports from production data

- Automotive manufacturers can process supplier documentation and contracts without manual intervention

8. Safety monitoring

AI-powered safety monitoring uses video analysis and sensor data to detect unsafe behaviors, missing PPE, and dangerous proximity situations in real-time. This improves safety compliance and enables faster response when incidents or unsafe conditions are detected.

Real-world applications of AI-driven safety monitoring in manufacturing include:

- Construction companies ensuring hard hat compliance across job sites

- Chemical manufacturers monitoring for proper protective equipment in hazardous areas, preventing accidents before they occur

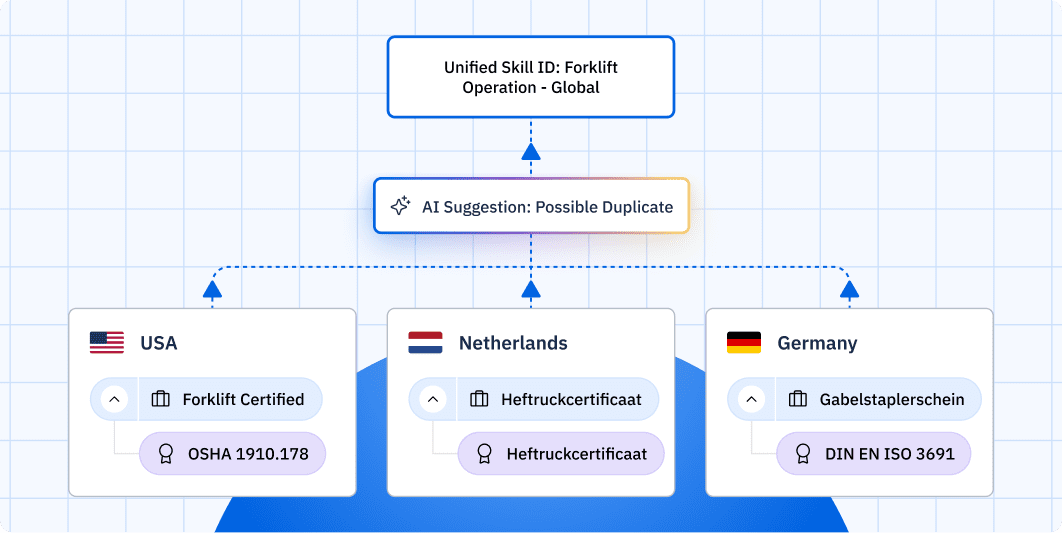

9. Skills management & workforce optimization

AI transforms workforce planning by mapping employee skills, training history, and certifications to optimize role assignments and identify development needs.

For example:

- Manufacturing companies can ensure certified technicians are assigned to critical equipment maintenance, while creating customized reskilling paths for workers transitioning to new technologies

10. Business intelligence & decision support

AI is able to aggregate operational and workforce data into intuitive dashboards that allow employees to make better decision without requiring technical expertise.

For example:

- Production managers identify efficiency trends across shifts, while quality control supervisors query systems in plain English to understand defect patterns and receive automated alerts about potential issues.

What’s at stake when manufacturers lack visibility into AI skillsCopied

Without clear visibility into who possesses critical AI skills, manufacturers face substantial operational risks. Unlike traditional manufacturing skills that remained stable for years, AI-related competencies constantly evolve, creating dangerous blind spots in resource allocation and emergency response.

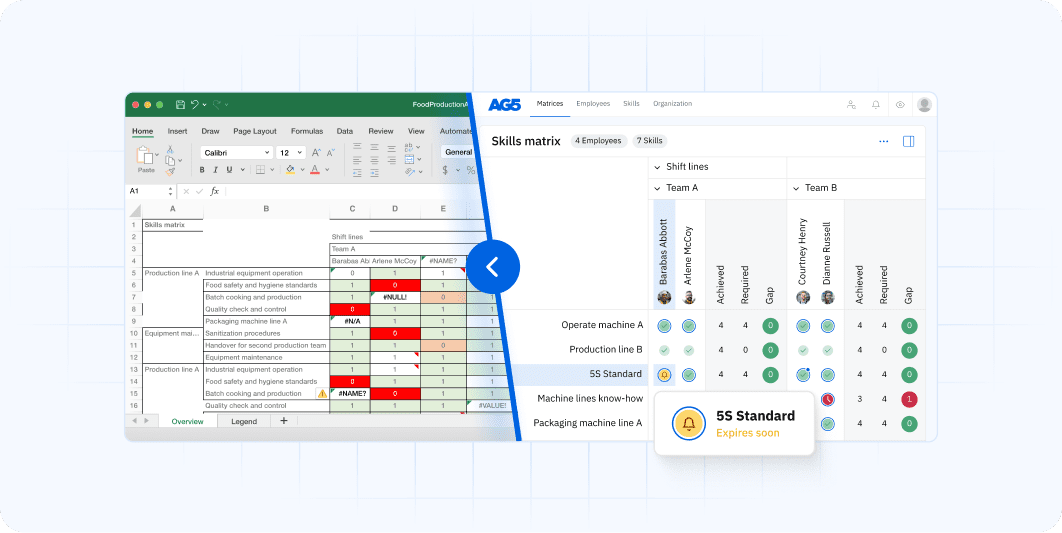

Why traditional tools fall short with AI skillsCopied

Excel spreadsheets and outdated systems cannot keep pace with rapidly evolving AI skills. These approaches suffer from static data that quickly becomes obsolete, fragmented information across multiple systems, and manual processes that rely on self-reporting. They also provide no insight into skill gaps or development pathways.

How AG5 bridges the AI skills visibility gapCopied

AG5’s platform provides comprehensive solutions to visibility challenges:

- Real-time skills visibility. Through constantly updated skills matrices showing workforce capabilities across teams, departments, and sites. Managers immediately see which workers are certified for specific AI systems

- Streamlined compliance and training. By automatically tracking certifications and renewals, integrating with your LMS, and providing clear visibility into competency development

- Reduced onboarding time. Through clear visibility into required competencies and personalized learning paths tailored to specific roles

- Data-driven decision-making. Via centralized workforce data analysis to identify skill gaps, predict training needs, and optimize recruitment strategies

- Employee empowerment. By providing clear visibility into skills profiles and career development opportunities, fostering engagement and improving retention

FAQs Copied

-

What are AI skills in manufacturing?

-

Why are AI skills important in robotics and automation?

-

How does AI improve manufacturing operations?

-

How can manufacturers manage AI-related skills more effectively?

-

What is a skills matrix and how does it help with AI skill tracking?

-

How does AG5 support AI skills management?

Sources Copied

- Change view: Table

-

APA

| # | Source title | Description | Publication | Retrieved | Source URL |

|---|---|---|---|---|---|

| 1 | Survey: 90% of manufacturers are using AI, but many feel they lag behind competitors | Smart Industry | May 31, 2024 | August 8, 2025 | https://www.smartindustry.com/.. |

| 2 | Artificial Intelligence (AI) in Manufacturing Market Size - By Component, By Deployment Model, By Technology, By Application, By End Use, Growth Forecast, | GM Insights | January 1, 2025 | August 8, 2025 | https://www.gminsights.com/ind.. |

| 3 | Future of Jobs Report 2025 | World Economic Forum (WEF) | January 1, 2025 | August 8, 2025 | https://reports.weforum.org/do.. |

| 4 | How AI-powered humanoid robots are changing auto manufacturing at BMW, Tesla, and Mercedes-Benz | Automotive Manufacturing Solutions | January 30, 2025 | August 8, 2025 | https://www.automotivemanufact.. |

| 6 | AI in Iron and Steel: Global Trends and Country-by-Country Analysis | ResearchGate | July 1, 2025 | August 11, 2025 | https://www.researchgate.net/p.. |

Author Copied

Revisions Copied

Written by: Rick van Echtelt

Copy edited by: Adam Kohut