Logistics skills management software for a qualified, compliant workforce

Managing logistics skills across shifts, sites, and certifications is complex. Logistics skills management software replaces error-prone spreadsheets with real-time visibility into qualifications, expirations, and gaps; helping teams assign the right people, reduce risk, and stay audit-ready.

Managing a logistics operation means keeping track of countless moving parts. People need to know how to handle materials safely, use equipment properly, and follow the right procedures. When your team spans multiple sites, shifts change constantly, and certifications expire without warning, keeping everyone qualified becomes a major challenge.

The traditional approach of tracking logistics skills in spreadsheets creates gaps that hurt operations. Someone shows up for a shift, but lacks certification for the forklift they need to drive. A team member handles hazardous materials without current safety training. An audit reveals compliance issues no one knew existed.

Skills management software solves these problems by providing a clear system that shows exactly which team members are qualified for specific tasks. AG5 is a skills management platform designed specifically for logistics and supply chain teams, helping track certifications, identify skill gaps, and ensure the right people handle the right tasks every day.

Understanding logistics skills and why they matterCopied

What are logistics skills?

When people ask about logistics skills, the question really centers on the specific capabilities required to keep supply chain operations running smoothly. These are practical skills teams use every day to move goods safely and efficiently, not abstract concepts.

Logistics skills cover everything from basic material handling to complex coordination tasks. Technical knowledge like operating equipment, procedural understanding like following safety protocols, and soft skills like communicating with carriers all play important roles. The exact skills needed depend on your operation type, though all logistics operations share common requirements around safety fundamentals and procedural compliance.

Why traditional tracking methods fail

Most logistics teams start with spreadsheets because they seem simple. A file gets created with names in one column and skills in others. Updates happen when someone completes training. Managers reference it when assigning work.

However, reality quickly complicates this approach. The spreadsheet lives on someone’s computer, making it inaccessible to other managers. Updates occur sporadically, leading to outdated information. Certifications expire without reminders. As a result, qualification gaps get discovered at the worst possible time, usually right when that person needs to do critical work.

Multi-site operations face even bigger challenges since each location maintains its own tracking system with different formats. When people need to move between locations or coverage needs comparing across the network, the process essentially starts from scratch.

How competency management software worksCopied

Centralized skills tracking

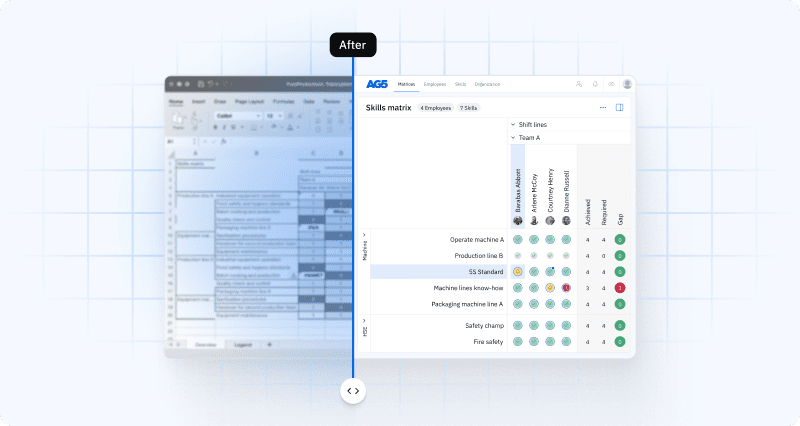

Competency management software takes a different approach from scattered spreadsheets. One central system houses all skills data, allowing every manager to see the same up-to-date information. Every team member gets a complete profile showing their current qualifications.

The system starts with a skills matrix, which structures how to define what competencies operations need and which roles require them. For example, forklift operators might need equipment certification, safety training, and load security knowledge. Warehouse supervisors need those same skills plus performance management and workforce planning capabilities.

Automated certification monitoring

The software handles time-based challenges through automated monitoring. Certifications have expiration dates, and the system tracks them all. Automated alerts go out before qualifications expire, giving time to schedule renewal training. This prevents situations where someone shows up for work only to discover their certification lapsed yesterday.

AG5 connects with existing systems to keep information current without manual updates. Integration with learning management systems automatically updates when someone completes training. Connection to HR platforms tracks when new hires join or people change roles. As a result, skills data stays accurate automatically.

Essential skills for different logistics rolesCopied

Frontline worker competencies

Frontline workers form the foundation of operations by handling materials, fulfilling orders, and keeping goods moving. Their skills focus on safe, accurate task execution.

Safe material handling ranks as the most critical competency. Workers must know proper lifting techniques, how to secure loads, and how to move items without causing damage or injury. This includes understanding weight limits, recognizing hazards, and using equipment correctly.

Picking and packing accuracy directly affects customer satisfaction, requiring workers to read orders correctly, identify the right items, verify quantities, and package goods appropriately. Equipment competency matters for both efficiency and safety, whether involving handheld scanners, pallet jacks, or powered equipment. Inventory discipline keeps operations running smoothly through accurate location management, precise cycle counts, and proper receiving processes.

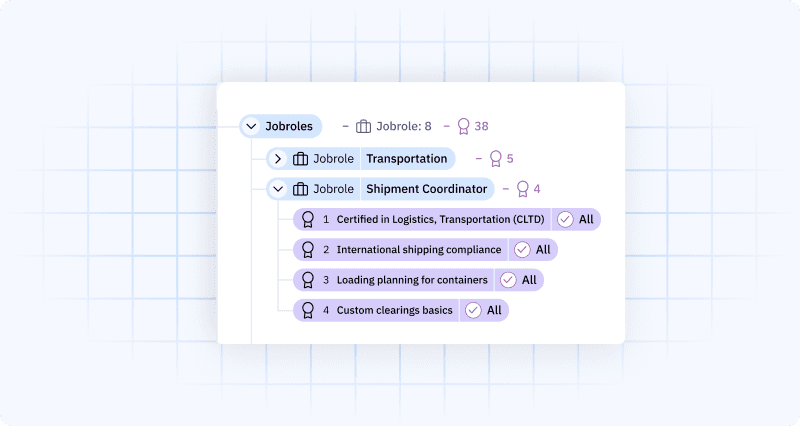

What skills does a logistics coordinator need?

Logistics coordinators bridge the gap between frontline execution and management oversight. Daily planning and problem-solving keeps shipments moving on schedule.

Shipment planning and prioritization require coordinators to juggle multiple factors including customer requirements, carrier schedules, and operational constraints. Then work gets sequenced in a way that meets deadlines without overwhelming the team.

Carrier and vendor coordination demands strong communication skills for scheduling pickups, handling delivery changes, and resolving issues. Documentation accuracy becomes more complex at this level, with coordinators managing exceptions, processing customs paperwork for international shipments, and ensuring all required information is complete and correct.

What skills does a logistics manager need?

Logistics managers operate at a strategic level with all the skills of coordinators plus additional capabilities for leading teams and managing operations.

Workforce planning and coverage management are crucial responsibilities. Managers forecast staffing needs, schedule teams effectively, and ensure adequate coverage for all required tasks. Cross-training strategy reduces operational vulnerability by identifying single points of failure where only one person has critical skills.

Performance management involves setting clear expectations, tracking metrics, and driving continuous improvement through analyzing bottlenecks, identifying root causes, and implementing solutions. Compliance oversight ensures training programs stay current, certifications get maintained, and audit requirements get met consistently.

Improving logistics skills systematicallyCopied

Defining clear proficiency standards

Many organizations invest heavily in training but struggle to prove it worked. They send people to classes, yet performance does not improve. Money gets spent on certifications, but operational problems persist. The missing piece is usually a systematic approach to skills improvement.

Effective skills improvement starts with clear definitions specifying what proficient means for each skill. Is a forklift operator proficient after basic certification, or do they also need to demonstrate speed and accuracy in your specific environment? Does picking proficiency mean meeting minimum standards or exceeding them consistently?

Assessing and closing skills gaps

Once proficiency levels get defined, they map to job requirements to create clarity about expectations. A warehouse worker knows exactly what skills need mastering. A coordinator understands what capabilities need developing for promotion. Managers can assess whether candidates have the right competencies for open positions.

Assessment evaluates where each team member stands today. Some skills are easy to verify through certifications or credentials, while others require observation or testing. The key is creating a baseline to measure improvement over time.

Gap identification happens when current skills get compared to requirements, showing where to focus training resources. Maybe your night shift lacks equipment operators, or perhaps your new coordinator needs development in exception handling. Instead of generic training programs, specific needs get targeted.

Making improvement measurable

Training gets assigned with clear deadlines because vague plans like we should train more people on forklifts rarely happen. Specific assignments with target dates get completed through formal programs, on-the-job coaching, or cross-training by experienced team members.

Re-assessment proves the training worked by verifying people can actually perform the skill after completion. This might happen through a practical test, supervisor observation, or demonstrated performance over time. Results get recorded in your skills management system for tracking progress.

Maintaining evidence over time is crucial for compliance and continuous improvement. Historical records showing who was trained, when they were assessed, and what the results were protect you during audits and help analyze training effectiveness. AG5 supports this entire process with live skills matrices, up-to-date integrations, and dashboards that make gaps visible.

Assigning qualified staff with confidenceCopied

Daily work assignment challenges

The practical value of skills management software shows up in daily work assignments. Every logistics operation faces matching available people to required tasks while ensuring everyone is properly qualified.

Consider a typical morning scenario where a shipment of hazardous materials arrives. Who on today’s crew is certified to handle it? Without a skills management system, checking multiple sources becomes necessary. Maybe the supervisor gets called to ask, or training records get searched, or assumptions get made that someone knows.

With competency management software, the answer is instant. Opening the system, filtering for the required certification, shows exactly which team members are qualified. When their certifications expire also becomes visible, revealing whether they can handle similar shipments next month.

Reducing operational risk

Specialized equipment creates even more critical needs. Operating powered equipment without proper authorization creates serious safety and liability risks. Insurance might not cover incidents involving unauthorized operators, and regulatory agencies impose penalties for non-compliance. Beyond legal issues, untrained operators are more likely to cause accidents or damage.

Customer-specific requirements add another layer of complexity. Some customers have their own quality or handling procedures that only trained staff can perform. Skills management software helps map these requirements systematically by tagging tasks with required competencies. The result is fewer surprises, better coverage, and less rework across operations.

Maintaining compliance and audit readinessCopied

The certification expiration challenge

Compliance management in logistics can feel like a constant battle. Regulations change, certifications expire, and auditors ask for documentation that seems to be missing. The stress compounds when managing multiple sites with different requirements.

The core problem is that certifications are time-limited. A forklift certification might last three years, safety training expires annually, and equipment authorizations need renewal every six months. Multiply these timelines across dozens or hundreds of employees, and tracking expiration dates becomes overwhelming.

Manual tracking fails in predictable ways. Expiration dates get entered in a spreadsheet, but no one checks it regularly. Employees are relied upon to report when they need renewal training, but they forget or assume someone else is tracking it. Expired certifications get discovered only when preparing for an audit or after an incident occurs.

Automated compliance monitoring

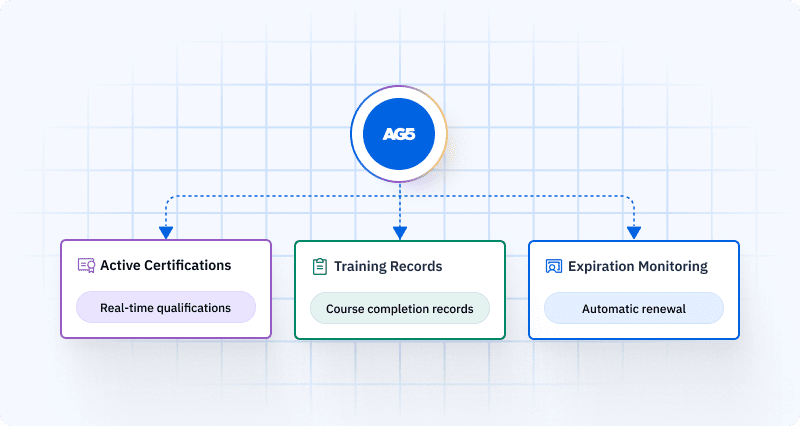

AG5 solves this through automated expiration alerts that monitor all certification dates and send notifications well before they expire. Managers get advance warning with enough time to schedule renewal training. As a result, continuous compliance gets maintained instead of scrambling to catch up.

The notification timing matters significantly. Getting an alert the day before a certification expires is not helpful since weeks or months of advance notice are needed, depending on training availability and scheduling complexity. Skills management software lets you configure these timelines based on your operational needs.

Building audit-ready documentation

Documentation requirements extend beyond just tracking certifications. During audits, regulators want to see processes for ensuring compliance, proof that only qualified people performed specific tasks, and evidence of training programs and assessment methods.

AG5 maintains complete historical records that satisfy audit requirements. Reports can get generated showing who held which certifications at any point in time. Proof can be provided that specific shipments were handled by appropriately trained staff. Systematic processes for monitoring qualifications and closing gaps can be demonstrated.

Managing skills across multiple sitesCopied

The multi-site coordination problem

Single-site logistics operations face plenty of skills management challenges. Multi-site operations face all those same challenges multiplied across each location, plus additional complexity from inconsistent practices and siloed information.

Each site tends to develop its own approach to tracking skills. One location uses a spreadsheet maintained by the operations manager, another uses a different spreadsheet with a different format, and a third keeps paper records in filing cabinets. When a company-wide view of capabilities is needed, a research project essentially begins.

Centralized visibility for better planning

The lack of standardization creates real operational problems. People cannot easily move between sites because qualifications are unknown. Training completion rates cannot be compared across locations. Best cross-training practices cannot be identified because each site works differently.

Skills management software solves these problems through centralization and standardization. Everyone uses the same system with the same definitions, allowing capabilities across all sites and shifts to be seen in real time. Managers at different locations can share successful training approaches and learn from each other.

This visibility enables better workforce planning by identifying which sites need additional training resources, spotting gaps in shift coverage before they cause problems, and moving people between locations confidently because their qualifications are known exactly.

AG5 provides reporting and dashboards that give leaders the big picture while letting site managers drill down into details. A regional director can see training completion rates across all locations. A site manager can see which team members on the upcoming night shift have the skills needed for tomorrow’s workload. This combination of strategic and tactical visibility improves decision-making at every level.

Integrating with existing business systemsCopied

Reducing duplicate data entry

Adding new software to your technology stack raises legitimate concerns. Does it require duplicate data entry? Will it work with existing systems? Is it something your team will actually use? These questions matter because technology that doesn’t integrate smoothly often gets abandoned.

AG5 addresses these concerns through integration capabilities that connect with your HR system to automatically update when employees join, leave, or change roles. Integration with learning management systems captures training completions without manual data entry. It can work with other operational systems to pull in relevant information about certifications and qualifications.

Improving data accuracy and sustainability

These integrations serve two key purposes. First, they reduce administrative burden since teams stop manually updating skills data in multiple places. Second, integrations improve data accuracy by eliminating manual data entry errors. When someone completes training in your LMS, that completion appears in AG5 immediately and accurately.

Getting started with your implementationCopied

Building your skills framework

Implementing skills management software might seem like a major undertaking. Concerns about time investment, change management challenges, or whether teams will adopt a new system are valid. However, the implementation process is more straightforward than most organizations expect.

The first step involves defining your skills framework by determining what competencies your operation needs and what proficiency levels make sense. Many organizations find it helpful to begin with AG5’s logistics skills matrix template, which provides a starting point based on common industry requirements that can be customized to match your specific operation.

Loading data and training users

Once your framework gets defined, load your current data including your team roster and their existing qualifications. Training your team comes next, with managers learning how to run reports and assign training while team members understand where to view their own skills profiles. The real value emerges when the system gets used for daily decisions, providing immediate answers about qualifications and advance warnings about expiring certifications.

Moving from reactive to proactive skills managementCopied

The shift from spreadsheet-based tracking to proper skills management software represents more than a technology upgrade. It represents a fundamental change in how workforce planning and operational risk get approached.

With spreadsheets, skills management is reactive. Problems get discovered when they cause operational disruptions. Expired certifications get found out when auditors point them out. Coverage gaps get realized when critical work cannot get done.

With competency management software, skills management becomes proactive. Gaps get seen before they cause problems, warnings arrive before certifications expire, and training can be planned based on upcoming needs rather than scrambling to catch up with current crises.

This shift matters because logistics operations cannot afford surprises. When shipments arrive, qualified staff must be ready to handle them. During audits, documentation must be immediately available to prove compliance. And when customers ask about quality processes, you need a systematic way to demonstrate staff competence.

AG5 provides the platform to make this transition successfully. The software tracks logistics skills and certifications across entire operations, integrates with existing systems to reduce administrative burden, and gives managers real-time visibility into coverage and capabilities. Most importantly, it transforms skills management from a stressful guessing game into a systematic process you can rely on.

See how AG5 helps logistics teams manage skills at scaleCopied

Ready to move beyond spreadsheets? Book a demo to see how AG5 tracks logistics skills, automates certification visibility, and gives leaders real-time coverage insights. Learn how other logistics teams have transformed their workforce planning and reduced compliance stress with systematic skills management.

FAQs Copied

-

What skills are needed for logistics?

-

What are logistics skills?

-

How to improve logistics skills?

-

What is skills management software?

-

How does competency management software help with compliance?

-

Can skills management software work with multiple sites?

-

What is a logistics skills matrix template?

-

How does AG5 integrate with existing systems?

Author Copied

Revisions Copied

Written by: Rick van Echtelt

Copy edited by: Adam Kohut