Why food and beverage skills management is becoming critical for audit readiness

Food production requires trained, qualified workers. See how food and beverage skills management tracks employee training, certifications, and qualifications to maintain compliance. Discover why operations are moving from spreadsheets to dedicated systems for workforce tracking.

Food and beverage production depends on having the right people with the right skills in the right roles. Skills management is the systematic approach to identifying, tracking, and developing the competencies your workforce needs to operate safely and efficiently.

In the food industry, this takes on special importance. Unlike many other sectors, food production faces strict regulatory requirements, high turnover rates, and serious consequences for training gaps. A worker operating equipment without proper certification or someone handling allergens without current training isn’t just an HR issue–it’s a safety and compliance risk that can lead to recalls, injuries, or failed audits.

Food and beverage skills management software provides a structured way to track employee qualifications, training completion, and certification status. As a result, operations managers can verify workforce readiness, plan training needs, and maintain the documentation required for regulatory compliance.

Why traditional tracking methods fall shortCopied

Most food and beverage operations start by tracking workforce skills in spreadsheets or paper files. Initially, this approach works well, especially for smaller teams. However, as operations scale, these manual systems create serious gaps.

The version control problem

When multiple people maintain separate spreadsheets, you end up with conflicting information. For instance, the training coordinator updates their version, while the site manager has another, and HR maintains a third. No one knows which version reflects current reality. By the time you discover a certification has expired, the deadline has already passed.

The manual alert problem

Spreadsheets can’t notify you when action is needed. Someone has to manually review every row, every week, checking expiration dates against the calendar. This manual process is time-consuming and error-prone. Things inevitably slip through, especially during busy periods.

The reporting problem

When an auditor asks for documentation, you need to compile data from multiple sources. Hours are spent creating reports, never with full confidence you’ve captured everything. Furthermore, the process becomes even more challenging when you need to report across multiple facilities.

The scalability problem

What works for 50 employees becomes unmanageable at 500. Manual effort grows exponentially with team size. Eventually, you need dedicated staff just to maintain training records, and even then, accuracy suffers.

![]()

These problems aren’t theoretical. Instead, they represent the daily reality for many food production operations. Modern compliance management software for the food industry addresses these challenges by centralizing information, automating alerts, and enabling instant reporting.

Core components of effective skills managementCopied

Effective skills management in food and beverage operations requires several key components working together. Understanding these elements helps you evaluate whether your current approach is comprehensive enough.

Skills inventory and role mapping

Start by defining what skills and certifications each role requires. Production operators need different competencies than QA staff or maintenance technicians. A comprehensive skills inventory documents these requirements clearly.

For example, a production line operator might need:

- Basic food safety certification

- Allergen awareness training

- Equipment-specific operation training

- Good Manufacturing Practices (GMP) training

- Safety procedures and emergency response

A skills matrix helps visualize these requirements. It shows which skills each role needs and which employees have those skills. Consequently, this visual approach makes gaps immediately obvious.

Training completion tracking

Once you know what training is required, you need to track who has completed it. This means recording training dates, maintaining proof of completion, and noting when refresher training is due.

Good training tracking includes several elements. First, individual training records for each employee showing their complete training history. Second, course-level views showing who has completed specific training and who still needs it. Third, team or department views showing overall completion rates.

Many operations integrate their skills management system with their learning management system (LMS). When someone completes a course in the LMS, that information automatically updates their training record. This eliminates double data entry and keeps information current. Learn more about integrations that connect training systems with skills management.

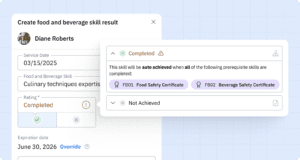

Certification and credential management

Certifications differ from training in that they have formal expiration dates and often require specific renewal processes. Managing certifications effectively means tracking not just whether someone has a credential, but when it expires and what’s required for renewal.

Common certifications in food and beverage operations include:

- Food safety certifications (ServSafe, HACCP)

- Equipment operation licenses (forklift, powered industrial truck)

- Quality control certifications

- First aid and emergency response

- Specialized process certifications

Effective certification tracking includes the certificate itself (stored digitally), the issue date, the expiration date, and any renewal requirements. Systems should alert you well before expiration so you can schedule renewals without letting certifications lapse.

Gap analysis and planning

Gap analysis compares your current workforce skills against requirements. It answers questions like: Which roles have insufficient training coverage? Which certifications are about to expire? Where are we vulnerable if someone leaves or transfers?

This analysis becomes especially important when planning for growth or changes. If you’re adding a new production line, gap analysis shows exactly what training your current staff needs or what skills new hires should have. Additionally, if you’re implementing a new process, you can identify who needs training before the change happens.

Good gap analysis also helps with budget planning. When you can see all upcoming training and certification renewals, you can budget more accurately. This is valuable for expensive specialized training or certifications that require external instructors.

Compliance and audit readinessCopied

Food and beverage operations face regular audits from multiple sources: regulatory agencies, customer audits, certification bodies, and internal quality reviews. Workforce qualifications are always part of these audits.

What auditors verify

Auditors typically want to verify several things:

- Employees performing specific tasks have the required training

- Certifications are current, not expired

- Training records are complete and accessible

- There’s a system to ensure ongoing compliance

The importance of documentation

The difference between passing and failing often comes down to documentation and organization. You might have trained people appropriately, but if you can’t prove it quickly during an audit, you risk findings or non-conformances.

This is where compliance software for the food industry provides clear value. Systems designed for audit readiness let you generate reports instantly, showing exactly who is trained for what. You can produce evidence on demand rather than scrambling to compile it when auditors arrive. Having compliance reports ready to go transforms audits from stressful events into routine verifications.

Industry-specific workforce challengesCopied

Food and beverage operations face workforce management challenges that are more acute than in many other industries.

High turnover rates

Food production experiences some of the highest turnover rates across all manufacturing sectors. This constant churn means you’re always onboarding new people and ensuring they receive required training. Traditional tracking methods struggle to keep up with this pace of change.

Seasonal fluctuations

Many food operations experience seasonal peaks requiring temporary workers. You need to onboard these workers quickly, ensure they’re properly trained, and maintain records even after they leave. When they return the following season, you need to know what training they already completed and what needs renewal.

Multiple shifts and locations

Food production often runs 24/7 across multiple facilities. Coordinating training across different shifts and sites is complex. You need to ensure every shift has adequate coverage of qualified personnel, not just the day shift at your main facility.

Language diversity

Food production workforces are often multilingual. Training materials and records need to account for this diversity. You need to verify understanding, not just attendance.

Varying skill levels

Production roles might require basic certifications, while QA roles need advanced technical training, and maintenance staff need specialized equipment knowledge. Managing these different requirements simultaneously requires flexibility in your tracking system.

These challenges explain why dedicated food industry compliance software exists. Generic HR systems or simple spreadsheets weren’t designed with these specific complications in mind.

Building an effective skills management systemCopied

Whether you’re improving an existing system or starting from scratch, building effective skills management follows a logical progression.

Define your requirements

Start by documenting what skills, training, and certifications each role requires. Involve supervisors and subject matter experts in this process. They know what’s actually needed on the floor, which sometimes differs from what formal job descriptions say. A food and beverage skills matrix template can provide a starting point that you customize for your operation.

Audit your current state

Gather existing training records, certificates, and documentation. This often reveals gaps you didn’t know existed. You might discover that training you assumed happened was never documented, or that certifications expired months ago without anyone noticing.

Choose your tools

Decide whether to improve your current spreadsheet system or move to dedicated software. Consider your operation’s size, complexity, and growth plans. Small single-site operations might manage with enhanced spreadsheets. Multi-site operations with hundreds of employees typically need dedicated systems. Explore how skills management software works to understand what’s available.

Migrate your data

Transfer existing records into your new system. This is time-consuming but crucial. Incomplete migration means you’ll need to maintain two systems temporarily, which defeats the purpose.

Establish processes

Define how information flows into the system. Who updates training records? How quickly after training completion? Who reviews certification expirations? How do you handle exceptions? Clear processes prevent the system from becoming outdated immediately after implementation.

Train your team

Everyone who interacts with the system needs training. This includes training coordinators, supervisors who need to check qualifications, and HR staff who onboard new employees. Without adequate training, people revert to old methods.

Monitor and improve

After implementation, regularly review whether the system is working. Are people using it? Is information current? Are you catching certification expirations before they lapse? Use these insights to refine your processes.

Integration with existing systemsCopied

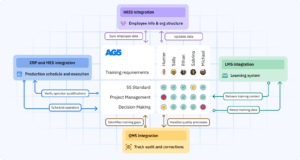

Food and beverage operations already use various systems: ERP for production planning, MES for manufacturing execution, QMS for quality management, HRIS for HR functions, and LMS for training delivery. Your skills management approach needs to work with these systems, not replace them or create duplicate work.

ERP and MES integration

These systems handle production scheduling and execution. Skills management can integrate to verify that scheduled operators have the required qualifications for their assigned tasks. This prevents situations where someone is scheduled to operate equipment they’re not certified to use.

HRIS integration

Your HR system maintains employee records, job titles, and organizational structure. Syncing this information with your skills management system eliminates duplicate data entry. When someone gets hired, promoted, or transfers, that change automatically updates in both systems.

LMS integration

Your learning management system delivers training content. When someone completes a course, that completion should automatically update their skills record. This real-time sync keeps training data current without manual intervention.

QMS integration

Quality management systems often track audit findings and corrective actions. If an audit identifies training gaps, that finding should connect to your skills management system so you can track remediation.

The key principle is that skills management complements your existing food and beverage business management software rather than competing with it. Each system has its specialty. Your ERP handles production planning, your QMS handles quality processes, and your skills management system handles workforce readiness. Check what features support integration with your existing technology stack.

Common implementation pitfalls to avoidCopied

Organizations implementing skills management systems often encounter predictable challenges. Learning from others’ mistakes can help you avoid them.

Making it too complex

The temptation is to track every possible skill in exhaustive detail. This creates so much administrative burden that people stop maintaining the system. Start with skills that are critical for safety and compliance. You can always add more detail later.

Inadequate change management

People resist new systems, especially if they don’t understand why it matters. Explain how skills management makes everyone’s job easier: supervisors can quickly verify qualifications, training coordinators spend less time on paperwork, and audits become less stressful.

Poor data quality at launch

If you migrate incomplete or inaccurate data, you’ll spend months cleaning it up. Take the time to get data right before going live. It’s painful upfront but saves enormous effort later.

No clear ownership

Someone needs to own the system–not just use it, but ensure it stays current and useful. Without clear ownership, the system gradually becomes outdated and people lose trust in its accuracy.

Forgetting about maintenance

Skills requirements change over time. New regulations emerge, processes evolve, and equipment gets replaced. Your skills management system needs regular review to ensure it reflects current reality, not how things worked two years ago.

Measuring skills management effectivenessCopied

How do you know if your skills management approach is working? Several metrics can indicate success or highlight areas needing improvement.

Training completion rates

What percentage of required training is completed on time? Declining completion rates suggest your processes aren’t working or people are overwhelmed with training requirements.

Certification compliance

How many employees have expired certifications? Zero expired certifications means your alert system is working and people are renewing on time. Regular expiration issues indicate process problems.

Time to qualification

How long does it take new hires to become fully qualified for their roles? Shorter times suggest efficient training processes. Extended times might indicate training bottlenecks or unclear requirements.

Audit findings

Are you getting workforce-related findings during audits? Frequent findings about missing training records or expired certifications mean your skills management needs improvement.

Administrative time

How much time do coordinators spend maintaining training records? Effective systems reduce administrative burden. If staff report spending more time on records than before, something isn’t working.

Cross-training coverage

Do you have adequate backup for critical skills? Good skills management reveals where you’re vulnerable if someone leaves or is absent. Improving coverage in these areas increases operational resilience.

How food and beverage companies approach skills managementCopied

Looking at how other operations manage workforce skills provides practical insights into what works.

Multi-site operations

Large companies with multiple production facilities need standardized approaches. They typically establish corporate-level requirements while allowing sites some flexibility for local needs. Centralized visibility lets corporate training teams see compliance across all locations while site managers focus on their own teams.

High-turnover environments

Operations with significant turnover focus on rapid onboarding. They create streamlined training paths for new hires, with clear checklists showing what training is required and in what sequence. This structure helps new employees become productive quickly while ensuring nothing gets missed.

Seasonal operations

Food companies with seasonal peaks maintain records of temporary workers from year to year. When seasonal employees return, they can quickly verify what training is still current and what needs renewal. This approach is much faster than treating returning workers as entirely new each season. Having custom training paths helps streamline this process.

Specialized production

Companies with specialized processes or equipment develop detailed competency frameworks. They track not just basic certifications but also advanced skills that take time to develop. This helps them identify and develop internal expertise rather than always hiring externally.

Taking the first steps toward better skills managementCopied

Improving skills management doesn’t require a complete overhaul all at once. You can start with focused improvements that build toward a comprehensive system.

Begin by documenting your current state honestly. What training records do you have? How complete are they? How do you currently track certifications? Where are the gaps? This assessment shows you where you are and clarifies what needs improvement.

Next, prioritize based on risk. Start with skills that have the biggest safety or compliance implications. If forklift certifications lapse, that’s a serious safety issue. If allergen training isn’t tracked properly, that’s a major food safety risk. Focus on high-impact areas first.

Consider starting with a pilot. Choose one department or one facility to test your improved approach. Work out the processes on a smaller scale before rolling out company-wide. This pilot also builds internal advocates who can champion the system to others. Explore resources that provide implementation guidance.

Set realistic timelines. Implementing comprehensive skills management takes months, not weeks. Rushing leads to poor data quality and resistance from staff. Plan for adequate time to migrate data, train users, and establish new processes.

Most importantly, remember that skills management is not a project with an end date. It’s an ongoing capability that requires continued attention and improvement. The initial implementation is just the beginning of a journey toward better workforce readiness and compliance.

Final thoughtsCopied

Effective food and beverage skills management transforms workforce compliance from a constant worry into a controlled process. You gain clear visibility into who is qualified, stay prepared for audits without last-minute scrambling, and renew certifications proactively before they expire.

The investment in better skills management pays dividends through reduced audit stress, improved operational efficiency, better training planning, and increased confidence in workforce readiness. Whether you improve your current spreadsheet approach or move to dedicated software, the key is having a systematic method that scales with your operation and keeps pace with constant workforce changes.

Food production will always require trained, qualified people. Skills management ensures you can prove they’re ready for the work they do.

FAQs Copied

-

What's the difference between training tracking and skills management?

-

Is AG5 regulatory compliance software for the food industry?

-

What's the difference between food and beverage skills management software and business management software?

-

Can I start with a template?

-

How does AG5 handle multiple facilities?

-

Does AG5 integrate with our existing systems?

-

What kind of certifications can AG5 track?

-

How long does it take to implement AG5?

Author Copied

Revisions Copied

Written by: Rick van Echtelt

Copy edited by: Adam Kohut