Warehouse skills management software for safer operations

Warehouse skills management software gives logistics teams real-time visibility into worker qualifications. By tracking certifications, training, and equipment authorizations in one system, warehouses can prevent coverage gaps, improve safety, and simplify compliance—especially during peak operational periods.

Warehouse skills management software solves one of the most persistent challenges in logistics operations: knowing exactly which workers have which qualifications at any given moment. Between tracking forklift certifications, monitoring picking accuracy, and planning shift coverage based on actual capabilities, warehouse managers need clear visibility into their team’s skills.

When warehouse skills tracking relies on spreadsheets or informal systems, critical details fall through the cracks. Certifications expire without warning. Managers scramble to find qualified workers for essential tasks. Compliance audits reveal gaps in documentation. These problems compound during peak seasons when operations are already stretched thin.

This guide explores how warehouse skills management software transforms operations by providing real-time visibility into worker qualifications, automating certification alerts, and enabling skills-based planning that reduces coverage gaps and improves safety.

Understanding warehouse skills and why they matterCopied

Warehouse skills encompass the specific abilities and certifications workers need to perform their jobs safely and effectively. These range from basic operational competencies to specialized equipment authorizations that require formal training and regular renewal.

Most warehouse skills fall into three categories. Operational skills include picking accuracy, packing procedures, inventory management, and quality control processes. Equipment certifications cover forklift operation, order picker authorization, and dock equipment handling. Safety and compliance skills ensure workers understand PPE requirements, hazmat procedures, and emergency protocols.

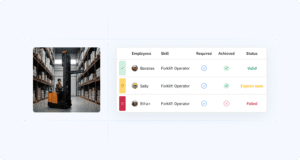

The challenge is not just identifying which warehouse skills your operation needs. The real difficulty lies in tracking who has which skills, when certifications expire, and where gaps exist across your workforce. A well-designed skills matrix provides visual clarity into these workforce capabilities, showing at a glance which workers possess which qualifications.

Essential warehouse skills by roleCopied

Warehouse worker skills

Entry-level warehouse workers need foundational skills that enable safe, accurate work. Safety awareness tops the list because warehouse environments present constant hazards. Workers must understand proper lifting techniques, maintain situational awareness around moving equipment, and follow pedestrian separation protocols.

Picking and packing accuracy directly impacts customer satisfaction. Workers need attention to detail to select correct items, verify quantities, and catch errors before products ship. Small mistakes at this stage create expensive returns and damage customer relationships.

RF scanner operation has become essential in modern warehouses. Workers must scan barcodes accurately, navigate warehouse management systems, and troubleshoot common issues. Understanding how to interpret system messages when discrepancies appear saves time and prevents inventory errors.

Basic inventory practices include proper bin discipline, participation in cycle counts, and recognizing when stock levels look incorrect. Workers should understand FIFO practices for perishable goods, lot tracking for regulated products, and serial number management for high-value items.

Warehouse manager skills

Warehouse managers require different capabilities focused on planning, coaching, and process improvement. Skills-based shift planning means building schedules around actual qualifications rather than just headcount. Managers must know which workers hold which certifications and ensure adequate coverage for all essential functions.

Cross-training coordination reduces single points of failure. Smart managers identify critical warehouse skills and ensure multiple workers can perform each key task. This flexibility prevents operational disruptions when specific workers are unavailable.

Performance coaching works best when managers have clear data on current skills and training completion. Rather than relying on memory, managers need systems that show who is ready for additional responsibilities and where skill gaps require attention.

Safety enforcement and incident response require managers to maintain documentation of safety training, conduct audits, and respond quickly when issues arise. Accurate records become essential during compliance reviews and incident investigations.

Equipment certifications and authorizationsCopied

Equipment-related warehouse skills require formal training and certification. These authorizations ensure safe machinery operation and typically need renewal on regular schedules.

Forklift certifications are among the most common warehouse requirements. However, different equipment types require separate authorizations. Counterbalance forklifts, reach trucks, order pickers, and pallet jacks each present unique operating characteristics and safety considerations.

Tracking which workers hold which specific equipment certifications becomes essential for shift planning. When certifications expire, workers cannot legally operate that equipment until they renew. This creates sudden coverage gaps that disrupt operations and force managers into reactive mode.

Loading dock operations require specialized knowledge about weight distribution, proper securement, and dock safety protocols. Workers need training on dock locks, trailer inspection, and loading practices that prevent product and equipment damage.

Common warehouse skills management challengesCopied

Even well-run warehouses face recurring skills management issues. Understanding these challenges helps build better systems to address them.

Scattered information across multiple systems

Warehouse skills data often exists in multiple locations. HR maintains certification files. Individual supervisors track training completion. Equipment authorizations live in separate databases. When managers need answers to basic questions, they waste time hunting through disconnected systems.

Using a structured warehouse management skills matrix template centralizes this information, giving managers a single source of truth for workforce capabilities. This eliminates the frustration of checking multiple spreadsheets to answer simple questions like who can operate specific equipment on the second shift.

Expired certifications causing compliance gaps

Manual tracking makes it easy to miss certification expiration dates. By the time someone realizes a license has lapsed, coverage problems already exist. Worse, letting workers operate equipment with expired certifications creates serious liability exposure during safety incidents or audits.

Systems with certificate storage and expiring qualification alerts solve this problem by notifying managers well before renewals are due. This shifts operations from reactive scrambling to proactive planning.

Difficulty scaling during peak seasons

Seasonal peaks strain warehouse operations through rapid hiring and increased volume. Managers must onboard temporary workers quickly while maintaining safety and productivity standards. Without clear skills tracking, deploying new hires effectively becomes guesswork.

Which temporary workers completed safety training? Who has prior forklift experience? Which areas still need coverage? These urgent questions during peak periods demand immediate answers that scattered systems cannot provide.

Limited visibility for strategic planning

Operations leaders need aggregate views of workforce capabilities across facilities. How many certified forklift operators do we have company-wide? Where are the biggest skill gaps? Which locations need training investment?

When warehouse skills data lives in site-specific spreadsheets, answering these strategic questions becomes nearly impossible. Leaders make decisions based on incomplete information, missing opportunities to optimize training budgets and workforce allocation.

How warehouse skills management software solves these problemsCopied

Purpose-built warehouse skills management software addresses the limitations of manual tracking by centralizing data, automating alerts, and enabling skills-based planning.

Centralized skills visibility

Software platforms provide a single database where all warehouse skills information lives. Everyone sees current data reflecting the latest training completions and certification renewals. This eliminates version control issues and ensures accuracy across the organization.

Managers can quickly answer questions about workforce capabilities without manual data compilation. Who can operate reach trucks today? Which teams are short on required qualifications? Where do we need cross-training to reduce bottlenecks? These answers appear instantly through real-time reporting.

Automated certification management

The system tracks certification issue dates and expiration dates for every qualification. Automated alerts notify managers 60 or 90 days before renewals are due, providing adequate time to schedule training without creating urgency.

This proactive approach prevents the compliance gaps and operational disruptions that occur when certifications lapse unexpectedly. Workers maintain continuous authorization to operate equipment, and managers avoid last-minute scrambling to find coverage.

Skills-based scheduling and planning

Integration capabilities connect warehouse skills data to workforce planning systems. This enables managers to build schedules based on actual qualifications, with automatic checks that flag when someone is assigned to tasks they are not qualified to perform.

These guardrails prevent costly mistakes before they happen. Operations run more smoothly because every assignment matches a qualified worker to the appropriate task.

Scalable templates and frameworks

Organizations can accelerate implementation by starting with proven frameworks rather than building from scratch. These templates capture industry best practices while remaining flexible enough to accommodate unique requirements across different facilities and operational models.

Templates enable organizations to start tracking essential warehouse skills immediately and expand their approach over time as they identify additional competencies to monitor.

Implementing warehouse skills management softwareCopied

Moving from spreadsheets to dedicated software requires planning but delivers significant returns through improved visibility and reduced administrative burden.

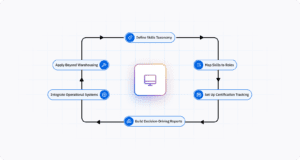

Define your warehouse skills taxonomy

Start by listing all warehouse skills your operation requires. Group them into logical categories like operational tasks, equipment authorizations, safety procedures, and quality requirements. Be specific enough to enable useful tracking without creating overwhelming complexity.

For example, forklift operator is too broad if you have multiple equipment types. However, tracking every possible loading pattern separately creates unnecessary detail. Find the right level of granularity for your needs.

Map skills to roles and requirements

Connect each warehouse skill to the specific job roles that require it. This creates clear expectations for workers and managers about role requirements. It also enables straightforward gap analysis showing which workers are fully qualified and which need additional training.

Role mapping supports better hiring decisions by defining exactly what qualifications new workers need. It also helps with succession planning by identifying which skills workers need to develop for advancement.

Establish certification tracking processes

For every time-sensitive qualification, record issue dates and expiration dates. Configure alert timing based on how long training scheduling typically takes at your organization. Some certifications may need 90-day advance notice while others work fine with 60 days.

Store certificate copies in the system where authorized personnel can access them during audits. Being able to produce proof of current certifications instantly prevents compliance issues and demonstrates your commitment to safety standards.

Build reporting that drives decisions

Configure reports that answer your most frequent questions. Who can perform specific tasks right now? Which certifications expire in the next quarter? Where do we have skill gaps by shift or location? Which workers are ready for cross-training opportunities?

These views should generate automatically without manual data compilation. When managers can answer questions in seconds instead of hours, they make better decisions faster and spend less time on administrative work.

Connect to your operational systems

Explore how warehouse skills management software connects to your existing technology stack. Connections to scheduling systems enable skills-based planning. Links to HR platforms sync hiring and training data. Integration with warehouse management systems provides operational context.

The more connected your skills data becomes to actual operations, the more value you extract from the system. These connections turn skills management from a compliance exercise into a strategic operational advantage.

Industry applications beyond warehousingCopied

While this guide focuses on warehouse skills, similar principles apply across logistics and supply chain operations. Transportation companies track driver qualifications and safety certifications. Distribution centers manage skills across multiple locations. Manufacturing operations coordinate technical competencies with production requirements.

Organizations in these adjacent industries face the same fundamental challenge: matching qualified workers to tasks while maintaining visibility into certifications and training completion across a distributed workforce.

Warehouse skills list with examplesCopied

Understanding which specific warehouse skills to track helps organizations build comprehensive skills management frameworks. Here are common examples organized by category.

Operational warehouse skills:

- Picking accuracy and order fulfillment

- Packing procedures and material handling

- RF scanner and handheld device operation

- Inventory cycle counting and bin discipline

- Quality inspection and damage assessment

- Shipping documentation and labeling

- Receiving procedures and verification

- Returns processing and restocking

Equipment certifications:

- Counterbalance forklift operation

- Reach truck authorization

- Order picker and cherry picker

- Pallet jack and walkie stacker

- Dock equipment and loading systems

- Yard truck and trailer movement

Safety and compliance:

- PPE requirements and proper usage

- Hazmat handling procedures

- Lockout tagout protocols

- Emergency response procedures

- Spill containment and cleanup

- Fire safety and evacuation

- Ergonomics and injury prevention

- Incident reporting and investigation

Warehouse manager competencies:

- Labor planning and scheduling

- Cross-training program development

- Performance coaching and feedback

- Safety audit and inspection

- KPI tracking and analysis

- Process improvement methodology

- Team communication and coordination

- Conflict resolution and problem-solving

Moving forward with warehouse skills managementCopied

Effective warehouse skills management transforms operations from reactive to proactive. When coverage issues emerge, managers who use skills management software plan confidently based on actual workforce capabilities rather than scrambling. Organizations renew qualifications on schedule instead of discovering expired certifications during audits. Teams work from verified skills data rather than guessing which workers can perform which tasks.

Warehouses that excel at skills management share common practices. They maintain centralized, current records of worker qualifications. Automated alerts for expiring certifications keep operations running smoothly. Building schedules based on skills data rather than assumptions becomes standard practice. These organizations make skills visibility a normal part of daily operations rather than something managers must work hard to achieve.

Whether you manage a single warehouse or oversee distributed logistics operations, improving skills management starts with understanding current capabilities and implementing systems that make workforce data accessible and actionable.

AG5 warehouse skills management software centralizes qualifications tracking, automates certification alerts, and enables skills-based planning across operations. The platform helps warehouses prevent coverage gaps, maintain compliance, and make better workforce decisions through real-time skills visibility. Schedule a demo to see how AG5 can transform your warehouse skills management.

FAQs Copied

-

What are warehouse skills?

-

What are the most important warehouse worker skills?

-

What skills do warehouse managers need?

-

How do you track warehouse skills effectively?

-

What certifications do warehouse workers need?

-

How often do warehouse certifications need renewal?

-

What is a warehouse skills matrix?

-

How does warehouse skills management software improve operations?

Author Copied

Revisions Copied

Written by: Rick van Echtelt

Copy edited by: Adam Kohut