Why automotive skills management affects audit results

Automotive manufacturing demands precise workforce qualification. This guide explains automotive skills management, the key skills and certifications to track, why spreadsheets fail at scale, and how modern skills management software helps teams stay audit-ready and reduce operational risk.

In automotive manufacturing, precision is everything. Every weld, every bolt, every inspection follows strict standards. But here’s the challenge: ensuring your entire workforce has the right skills and certifications to meet those standards, especially when you’re managing hundreds or thousands of employees across multiple shifts and locations.

That’s where automotive skills management becomes critical. When done right, it helps you track who can do what, where the gaps are, and which certifications are about to expire, all before problems hit your production line.

This guide explores what makes effective skills management in automotive manufacturing, the key skills your team needs to track, and how modern skills management software like AG5 can help you move beyond spreadsheets to a system that actually supports your operations. Whether you’re looking for the best automotive skills management solution or simply trying to understand which skills matter most in your plant, this article provides practical insights you can apply today.

Why automotive teams outgrow spreadsheets fastCopied

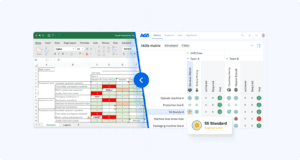

If you’re still managing workforce skills in spreadsheets, you’re not alone. Many automotive plants start there. The problem isn’t effort or commitment, spreadsheets fail because automotive operations move too fast and involve too many variables.

Here’s what happens in practice:

You have dozens of different roles, each requiring specific qualifications. A paint line operator needs different skills than a welding technician. An inspector on one station may not be qualified for another. As a result, you end up with hundreds of skill-role combinations that need tracking. This is precisely why organizations turn to structured skills management systems that can handle this complexity.

Then there’s the complexity of multiple sites. Plants run different shifts, use contractors and temporary labor, and need to maintain consistent quality standards across locations. When skills data lives in disconnected spreadsheets, you can’t see the full picture, and that makes planning nearly impossible.

Expiring certifications add another layer of risk. Forklift licenses, safety training, technical authorizations, these all have renewal dates. In a spreadsheet, these dates are easy to miss until someone shows up for a shift and realizes they’re not current.

Finally, when audit time comes, the scramble begins. You need to prove qualification coverage for critical processes, but the evidence is scattered across folders, email threads, and paper binders. Even with good intentions, pulling it together takes days of manual work.

This is why automotive teams need a proper skills matrix, a live system that tracks skills in real time and supports the way automotive operations actually work. The transition from spreadsheets to systematic skills management isn’t just about better organization. It’s about reducing risk, improving flexibility, and making workforce decisions based on accurate, current information instead of educated guesses.

What “best automotive skills management” actually means (a quick checklist)Copied

If you’re evaluating different approaches to managing automotive workforce skills, whether that’s software, systems, or processes, the best solutions tend to share five characteristics. These aren’t nice-to-haves. They’re the features that separate functional skills management from systems that actually improve operations.

Connect skills to real work

Generic job titles don’t tell you much in automotive manufacturing. You need to track skills at the level your operations actually run: by specific role, machine, process step, production line, and physical location. As a result, you can see exactly who’s qualified for each station, not just who has a similar-sounding job title.

Make gaps obvious and actionable

You shouldn’t need to rebuild a spreadsheet every week just to see where coverage is thin or who can step in when someone’s absent. The best systems make skill gaps immediately visible so you can take action before they affect output or quality. This kind of visibility becomes essential when you’re working with a competency management system that tracks both current state and future requirements.

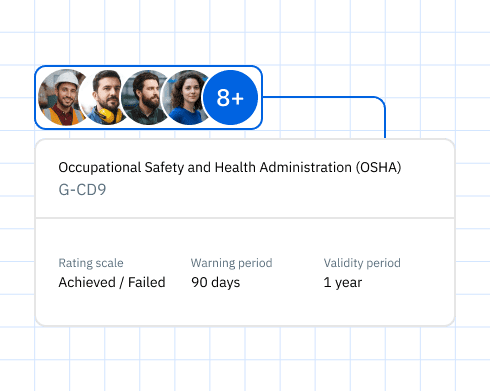

Handle certifications and evidence cleanly

Automotive work requires proof, of training completion, qualification dates, certification renewals. A good system stores that evidence, tracks expiration dates, and sends alerts before qualifications lapse. No more digging through files when an auditor asks for documentation.

Support audits without chaos

Customer audits, IATF reviews, internal quality checks, these happen regularly in automotive plants. The best skills management software lets you pull an audit-ready report in minutes, with the level of detail auditors expect. No more all-hands scrambles to compile documentation.

Work with your existing systems

Your HRIS holds employee data. Your LMS tracks training completion. A skills management system should connect to these tools through integrations, not create another data entry task. That way, information flows automatically and stays current across your stack.

AG5 is built around these requirements. It’s designed to make skills management operational, not just administrative, so you can focus on running production instead of chasing paperwork.

Skills needed in the automotive industryCopied

When automotive leaders search for “skills needed in the automotive industry,” they’re usually dealing with two realities at once. First, the work is highly technical and process-specific, each station, machine, and procedure has its own requirements. Second, quality and safety standards are non-negotiable, which means every skill needs documentation and proof.

Below, we’ll break down the most common skills to track in automotive manufacturing. These fall into two categories: core skills that apply across roles, and technical skills that are equipment- or process-specific.

Key skills in the automotive industry (core categories)

These are the foundational skills that support quality, safety, and operational consistency across automotive operations. They’re not tied to specific machines but are essential for anyone working in a manufacturing environment.

Quality and compliance skills

Automotive plants run on tight quality standards. That means employees need to understand inspection routines, defect handling procedures, traceability requirements, document control, and internal audit readiness. These skills ensure problems get caught early and recorded properly.

Safety and EHS skills

Safety isn’t optional in automotive manufacturing. Core safety skills include PPE compliance, hazard awareness, lockout/tagout procedures, incident response protocols, and ergonomic practices. These protect both people and operations from costly incidents.

Production and process discipline

Consistency drives automotive quality. Process discipline skills include standard work adherence, changeover routines, and understanding line balancing basics. When everyone follows the same process the same way, variation drops and throughput improves.

Problem-solving and continuous improvement

Problems happen. What matters is how quickly and effectively your team can respond. Skills like root cause analysis, corrective action development, and participation in Lean or Kaizen initiatives help teams improve processes systematically instead of firefighting the same issues over and over.

Team and shift skills

Automotive plants run 24/7 across multiple shifts. That requires strong handover practices, clear escalation paths, intentional cross-training, and the ability to communicate effectively under time pressure. These skills keep operations smooth when people rotate or situations change.

Technical skills in the automotive industry (examples you can track to task level)

Technical skills are where automotive skills management gets specific. These aren’t general capabilities, they’re tied to particular equipment, processes, or standards. As a result, tracking them requires precision. The exact technical skills you need to manage will depend on your plant configuration, product mix, and manufacturing processes. What matters is having a system that can adapt to your specific requirements without forcing you into generic categories that don’t match how your operation actually runs. Here are common examples:

Machine and equipment operation by station

Different machines require different operator qualifications. This includes presses, weld cells, paint lines, CNC equipment, assembly fixtures, and test rigs. Someone qualified on one press model may not be qualified on another, so tracking needs to be that granular.

Torque and fastening standards

Proper torque application prevents failures down the line. Operators need to understand calibration requirements, tool control procedures, and the specific torque values for different assemblies. This is both a technical skill and a critical quality control point.

Metrology and measurement equipment competency

Quality depends on accurate measurement. Employees who use gauges, calipers, CMMs, or other metrology equipment need specific training on those tools, and that training needs to be documented for audit purposes.

Robot cell and automation interaction

As automotive plants adopt more automation, operator-level skills around robot cells become important. This isn’t about programming robots, it’s about safely loading, unloading, and responding to error conditions in automated work cells.

Maintenance basics and TPM routines

Total productive maintenance (TPM) skills help operators handle basic upkeep tasks, reducing downtime and extending equipment life. These skills vary by role, not everyone needs them, but those who do need clear qualification tracking.

Material handling certifications

Forklift operation, overhead crane use, and other material handling tasks require formal certification. These expire on set schedules and need proactive renewal to avoid operational disruptions.

Process-specific certifications and refresher training

Many automotive processes require periodic requalification. Welding certifications, specific assembly procedures, quality inspection protocols, these often include refresher training on a 12- or 24-month cycle. A good skills management system tracks these renewal dates and flags them before they lapse. For more on how to handle industry-specific certifications in automotive, AG5 provides tools to manage these requirements across your entire workforce.

How automotive skills management software supports your operationsCopied

Understanding what skills you need to track is one thing. Actually managing those skills across a full manufacturing operation is another. This is where purpose-built skills management software makes a real difference.

Here’s how modern systems like AG5 support the day-to-day work of automotive teams:

Map skills to production processes, not generic job titles

Automotive plants don’t run on job titles. They run on processes, machines, and specific work instructions. AG5 lets you map skill requirements the same way, by linking qualifications to the actual work being done.

For example, instead of tracking “assembly technician skills,” you track skills for Station 12 on Line 3. When a process changes or new equipment arrives, you update the skill requirements to match. This keeps your skills matrix aligned with reality, which is essential when you’re trying to understand how it works in your specific operation.

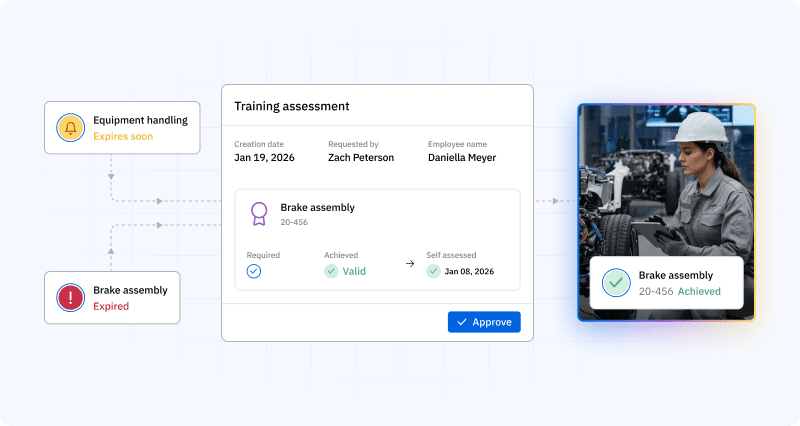

Proactively close gaps before they hit output

One of the biggest benefits of moving beyond spreadsheets is visibility. AG5 highlights skill gaps and sends alerts for expiring certifications automatically. As a result, you can schedule training, reassign coverage, or adjust staffing plans before problems reach the production floor.

This proactive approach prevents the common scenario where someone shows up for their shift and realizes their forklift certification expired last week, or where a key station sits idle because the only qualified operator called in sick. Instead of reacting to these situations after they happen, you can see them coming and take preventive action. This shift from reactive to proactive management has a real impact on operational efficiency and quality consistency.

Generate audit-ready reporting in minutes

Customer audits, IATF reviews, ISO assessments, these are regular events in automotive manufacturing. When an auditor asks for evidence of qualification coverage on critical processes, you need to produce a detailed, accurate report quickly.

With AG5, that report takes minutes instead of days. You can show exactly who was qualified for which processes during which time periods, complete with supporting documentation. This kind of audit readiness reduces stress and demonstrates operational control to customers and certification bodies.

Common use cases for automotive teamsCopied

Different departments benefit from automotive skills management in different ways. Here’s how various teams typically use a system like AG5:

Quality assurance

QA teams need to verify that only qualified personnel perform critical quality checks and inspections. With skills management software, you can confirm qualification coverage for every critical station, reduce defects by ensuring proper training, and produce standardized evidence when customers or auditors ask for proof of competency.

Training coordination and L&D

Instead of maintaining endless training lists, L&D teams can use skills data to prioritize what matters most. AG5 shows which skills are missing, which certifications are about to expire, and where training will have the biggest operational impact. This turns training from a compliance checkbox into a strategic activity tied to real business needs.

Operations and production planning

Production planners need to staff shifts based on actual readiness, not assumptions. With clear visibility into who can cover which stations, you can avoid downtime caused by missing qualified operators and improve flexibility by tracking who can step into adjacent roles when needed.

This kind of operational planning becomes even more powerful when you’re working across multiple facilities. The broader manufacturing industry page on AG5’s site shows how these principles apply beyond automotive to other manufacturing sectors as well.

Maintenance and technical teams

Maintenance work often requires specific technical authorizations and task-level competencies. Skills management software helps you track who’s qualified to work on which equipment, support role-based readiness during planned maintenance windows, and reduce risk when coverage shifts between sites or when contractors come on-site.

What makes AG5 different for automotive manufacturingCopied

There are plenty of tools that claim to manage skills. What sets AG5 apart is how it’s built specifically for operational environments like automotive manufacturing, where process precision, audit requirements, and multi-site complexity aren’t optional features, they’re daily realities. To see exactly how it works in practice, many teams start with a guided demo that shows their specific use case.

AG5 helps automotive teams replace outdated spreadsheets and reduce the operational drag of manual tracking. For example, automotive customers have highlighted outcomes like eliminating paper documentation, consolidating multiple departments into one unified system, and significantly reducing the time spent preparing for audits.

The platform connects to your existing systems through powerful integrations, adapts to your specific processes, and provides the kind of real-time visibility that makes workforce planning actually work. In other words, it’s not just a database of skills, it’s a system that supports how automotive operations run every day.

Moving from spreadsheets to systematic skills managementCopied

If you’re still managing skills in spreadsheets, the transition to dedicated software might feel like a big lift. But here’s the thing: the longer you wait, the more complex your spreadsheets become, and the harder they are to maintain.

Most automotive teams who make the switch find that the initial setup effort pays back quickly. You work with live data instead of rebuilding reports, get automatic alerts before certifications expire, and handle audits by pulling a report rather than scrambling at the last minute.

The key is starting with a clear picture of what you need to track. Focus on the skills that directly impact quality, safety, and throughput. Map those to your actual processes and roles. Then, as the system proves its value, you can expand coverage to additional skills and departments. Many successful implementations start with a single production line or critical process area, validate the approach, and then scale across the facility. This phased approach reduces risk and builds organizational confidence in the new system.

The real cost of manual skills tracking in automotive plantsCopied

When evaluating whether to invest in skills management software, it helps to understand what manual tracking actually costs your operation. These costs often stay hidden because they’re distributed across multiple departments and don’t show up as a single line item in the budget.

First, there’s the time cost. Someone, usually multiple people, spends hours each week updating spreadsheets, chasing down training records, and trying to figure out who’s qualified for what. That time could be spent on value-adding activities instead of data maintenance.

Then there’s the risk cost. Every time a certification expires unnoticed or an unqualified operator ends up on a critical station, you’re exposed to quality problems, safety incidents, and audit findings. These events can be expensive, both in direct costs and in damage to customer relationships.

There’s also an opportunity cost. Without clear visibility into skill gaps and coverage, you can’t optimize cross-training, plan succession effectively, or allocate training budgets where they’ll have the biggest impact. You’re making workforce decisions based on incomplete information, which means you’re probably leaving efficiency gains on the table.

Finally, there’s the stress cost. Manual systems create ongoing anxiety for supervisors, planners, and quality managers who know they don’t have complete visibility but are still responsible for outcomes. That stress affects decision-making and employee satisfaction in ways that are hard to quantify but very real.

When you add up these hidden costs, the investment in proper skills management software often pays for itself surprisingly quickly. The return isn’t just about efficiency, it’s about reducing risk, improving quality, and giving your team the tools they need to do their jobs well.

See how AG5 optimizes automotive manufacturing with better skills managementCopied

Ready to move beyond spreadsheets? AG5 helps automotive manufacturers track skills, close gaps proactively, and stay audit-ready, all in one system designed for operational teams.

Book a live demo to see how AG5 maps skills to your production processes, flags gaps early, and keeps your operation running smoothly.

FAQs Copied

-

What is automotive skills management?

-

What are the key skills in the automotive industry to track?

-

What are technical skills in the automotive industry?

-

Why is a skills matrix important in automotive manufacturing?

-

Is AG5 a skills matrix or a skills management platform?

-

How does skills management software help with audits?

-

Can AG5 integrate with existing HRIS and LMS systems?

-

How long does it take to implement skills management software?

Author Copied

Revisions Copied

Written by: Rick van Echtelt

Copy edited by: Adam Kohut