AG5 for manufacturing

Skills management software for manufacturing

Keep your operators certified, compliant, and ready — so you never lose production time to missing skills or outdated training.

- Maintain compliance with ISO, OSHA, and safety standards

- Reduce unplanned downtime with certified, skilled teams

- Prevent costly delays from expired or missing training

Trusted by leading manufacturing companies worldwide

Let AG5 ensure your workforce is certified and production-ready

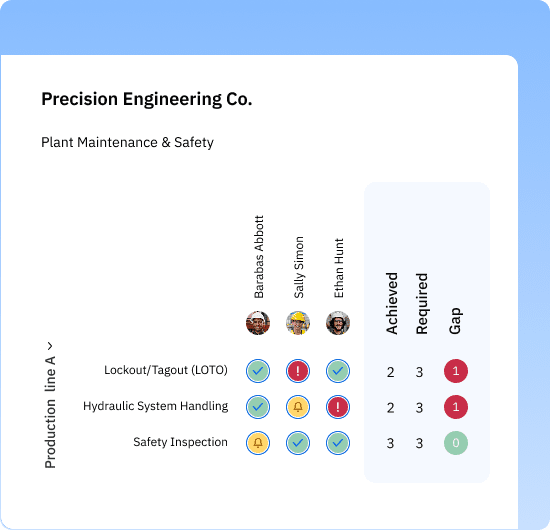

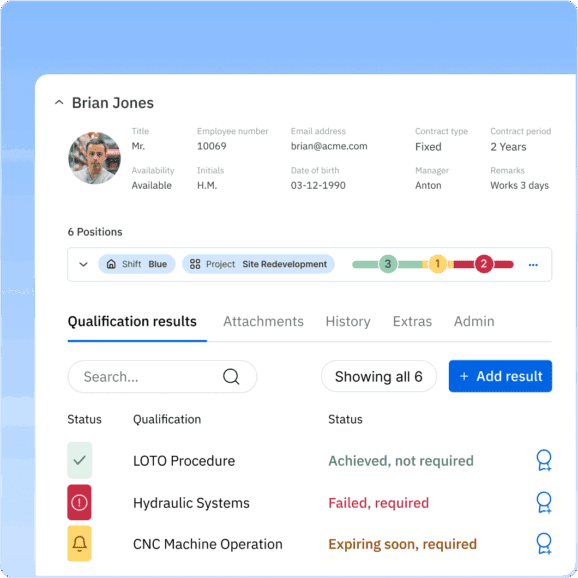

Never wonder if your shift has enough qualified operators

Get instant certainty about who’s authorized to run which machines — before a shift starts, not after something goes wrong.

Know exactly who can cover a workstation when someone calls in sick, and prevent unqualified operators from ever touching critical equipment.

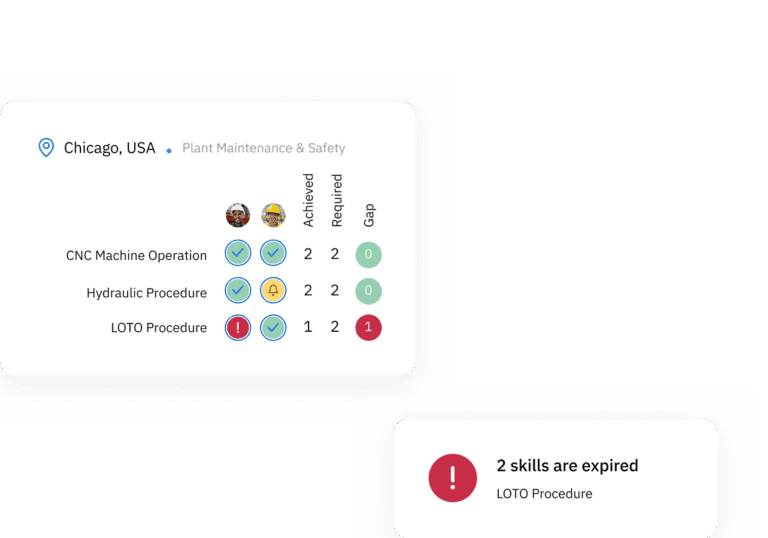

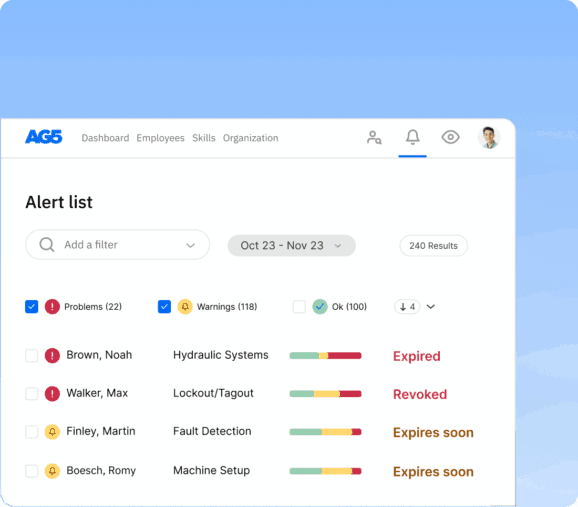

Spot skill gaps before they cause shutdowns

AG5 alerts you to expiring certifications and missing training before they halt production, trigger a failed audit, or put an unqualified operator on the floor.

With proactive warnings, you won’t scramble during shift changes, inspections, or machine breakdowns — you’ll stay ahead of every risk.

Avoid shutdowns, fines, and failed audits by meeting ISO and OSHA requirements

Ensure every operator meets ISO, OSHA, and equipment-specific safety requirements — so you never risk unqualified staff on the line.

If you fall out of compliance, the consequences are immediate: production stops, six-figure fines, failed audits, or lost customer contracts. With AG5, you always know who’s qualified and where your gaps are — before an inspector, customer, or attorney does.

Built for any frontline environment

AG5 supports manufacturers across industrial machinery, automotive, aerospace, electronics, food & beverage, medical, chemical, and plastics production — all with different safety rules, training needs, and compliance pressures.

Because we work with customers across these sectors, we understand their unique risks and requirements. AG5 gives every site the same advantage: real-time visibility into workforce skills to ensure safety, compliance, and uninterrupted production — no matter how different the industry demands are.

See how we’ve helped manufacturing companies like you

“We can instantly show certificates and competencies during audits. What used to take our team 4 weeks now takes 20 minutes. AG5 makes maintaining ISO compliance easy.”

“When we hired 40+ new staff in a short period, AG5 gave us the structure we needed — one place for all skills, certificates, and training. No more chaos or guesswork.”